Powering Through Problems: Your Ultimate Guide to Industrial Generator Set Troubleshooting

Industrial generator sets are the unsung heroes of continuous operations, providing critical backup power when the grid fails. From manufacturing plants and hospitals to data centers and construction sites, these robust machines are designed for reliability. However, even the most dependable equipment can encounter issues. Frankly speaking, understanding how to perform effective industrial generator set troubleshooting is not just a skill; it's a necessity for minimizing downtime and protecting your bottom line. In my experience, a proactive approach, coupled with a solid understanding of common problems, can save countless hours and significant expense.

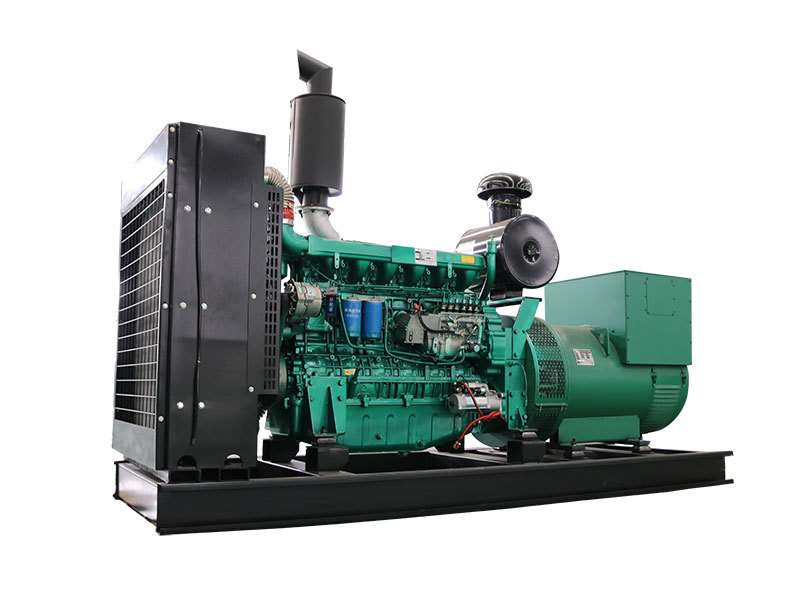

Understanding the Core Components and Their Roles

Before diving into troubleshooting, it's essential to have a basic grasp of what makes an industrial generator set tick. At its heart, a generator set comprises an engine (typically diesel or natural gas) and an alternator. The engine converts fuel into mechanical energy, which then drives the alternator to produce electrical energy. Supporting this core are several vital systems: the fuel system, cooling system, lubrication system, exhaust system, starting system, and control system. Each of these components plays a crucial role, and a failure in any one can lead to a shutdown.

The Engine: The Heartbeat of the Generator

The engine is where the magic begins. It needs clean fuel, proper lubrication, and adequate cooling to run efficiently. Issues here can range from fuel starvation to overheating.

The Alternator: Generating the Power

This is where mechanical energy is converted into electrical power. It involves complex windings and excitation systems. Problems here can manifest as no output, low output, or unstable voltage.

Supporting Systems: The Backbone of Reliability

The fuel, cooling, lubrication, exhaust, starting, and control systems are all interconnected. A clogged fuel filter, a leaky radiator hose, a low oil level, a blocked exhaust, a weak battery, or a faulty sensor can all bring the entire unit to a halt.

Common Industrial Generator Set Troubleshooting Scenarios

When an industrial generator set fails to start or run as expected, it can be a stressful situation. Fortunately, many issues fall into predictable categories. Let's explore some of the most common industrial generator set troubleshooting scenarios and how to approach them.

Scenario 1: The Generator Won't Start

This is perhaps the most frustrating problem. Several factors can prevent a generator from cranking or starting.

Fuel Issues: The Most Frequent Culprit

"Is there fuel in the tank?" This is the first question many technicians ask, and for good reason. Beyond just the level, check for:

- Clogged Fuel Filters: Over time, fuel can accumulate debris and water, blocking the filters. This is a common maintenance oversight.

- Air in the Fuel Lines: Air pockets can prevent fuel from reaching the engine. Bleeding the fuel system is often necessary.

- Faulty Fuel Pump: If the pump isn't delivering fuel, the engine won't start.

- Contaminated Fuel: Water or other contaminants can wreak havoc on the fuel system and engine.

Battery and Starting System Problems

The starting system relies heavily on a healthy battery.

- Dead or Weak Battery: The most obvious cause. Check voltage and ensure terminals are clean and tight.

- Faulty Starter Motor: If the battery is good but you hear no cranking or a grinding noise, the starter motor might be the issue.

- Bad Solenoid: The solenoid engages the starter motor. A faulty one will prevent cranking.

Electrical Control System Glitches

Modern generators have sophisticated control panels.

- Safety Shutdowns: The control panel might be preventing startup due to a perceived fault (e.g., low oil pressure, high coolant temperature, overspeed). Check the fault codes.

- Wiring Issues: Loose or damaged wiring to the starter or control panel can cause starting problems.

Scenario 2: The Generator Starts but Shuts Down Unexpectedly

This scenario often points to issues that arise once the engine is under load or has been running for a short period.

Overheating

An engine that overheats will trigger a shutdown to prevent damage.

- Low Coolant Level: Check for leaks in hoses, radiator, or water pump.

- Faulty Thermostat: A stuck thermostat can prevent coolant from circulating.

- Blocked Radiator Fins: Debris can impede airflow through the radiator.

- Malfunctioning Cooling Fan: The fan ensures adequate airflow, especially at low speeds.

Low Oil Pressure

This is a critical safety shutdown.

- Low Oil Level: Again, check for leaks and top up if necessary.

- Faulty Oil Pump: The pump might not be circulating oil effectively.

- Clogged Oil Filter or Passages: This restricts oil flow.

- Faulty Oil Pressure Sensor: The sensor might be giving a false reading.

Fuel Starvation Under Load

Sometimes, a generator will start fine but then shut down when the load is applied.

- Partially Clogged Fuel Filters: The engine can run on idle with restricted fuel flow, but not under demand.

- Issues with Fuel Tank Venting: A blocked vent can create a vacuum, preventing fuel flow.

Scenario 3: The Generator Runs but Produces No Power or Unstable Power

This points towards issues with the alternator or voltage regulation.

Alternator Problems

The alternator is responsible for generating electricity.

- Damaged Windings: Internal damage to the stator or rotor windings can cause power loss.

- Faulty Voltage Regulator: This component controls the output voltage. If it fails, you'll get no power or erratic voltage.

- Exciter Issues: The exciter provides the initial DC voltage to the rotor to create the magnetic field.

Loose Connections

Even a slightly loose connection at the output terminals or within the control panel can lead to intermittent power or complete loss. It's worth noting that corrosion can be a silent killer of electrical connections.

Preventative Maintenance: The Key to Avoiding Troubleshooting

Frankly speaking, the best way to deal with industrial generator set troubleshooting is to avoid it altogether. Regular, thorough preventative maintenance is paramount. Many experts agree that a well-maintained generator set is far less likely to fail when you need it most.

Regular Inspections and Checks

Daily or weekly checks should include:

- Visual Inspection: Look for leaks, loose wires, or any obvious damage.

- Fluid Levels: Check oil, coolant, and fuel levels.

- Battery Condition: Ensure terminals are clean and the voltage is adequate.

- Control Panel: Check for any warning lights or error messages.

Scheduled Maintenance Tasks

Follow the manufacturer's recommended schedule for tasks like:

- Oil and Filter Changes: Crucial for engine longevity.

- Coolant Flushes and Replacement: Maintains optimal engine temperature.

- Fuel Filter Replacement: Prevents fuel system contamination.

- Spark Plug/Injector Checks: Ensures efficient combustion.

- Load Bank Testing: This is a critical step for industrial generators. It involves running the generator under a simulated load to ensure it can handle its rated capacity and to burn off carbon deposits. Many technicians overlook load bank testing, which is a shame because it's incredibly effective for identifying subtle issues before they become major problems.

Advanced Troubleshooting and When to Call a Professional

While this guide covers common issues, some problems require specialized knowledge and tools. If you've gone through the basic troubleshooting steps and are still facing difficulties, or if the issue involves complex electrical components or internal engine problems, it's time to call in the experts. Attempting repairs beyond your expertise can lead to further damage or safety hazards.

Diagnostic Tools and Techniques

Professionals use tools like:

- Multimeters: For checking voltage, current, and resistance.

- Oscilloscopes: To analyze electrical waveforms.

- Scan Tools: For reading diagnostic trouble codes (DTCs) from the generator's control system.

- Infrared Cameras: To detect hot spots indicating electrical or mechanical issues.

Safety First!

Industrial generator sets operate with high voltages and potentially hazardous fuels. Always prioritize safety. Ensure the unit is properly grounded, disconnect power before working on electrical components, and wear appropriate personal protective equipment (PPE). Have you ever encountered a situation where a simple safety oversight led to a bigger problem? It's a good reminder for all of us.

The Importance of Documentation

Keeping detailed records of maintenance, repairs, and any troubleshooting performed is invaluable. This logbook provides a history of the unit, helping to identify recurring issues and informing future maintenance strategies. It's a fundamental part of effective industrial generator set troubleshooting and management.

Mastering industrial generator set troubleshooting is an ongoing process that combines knowledge, experience, and a commitment to preventative care. By understanding the common pitfalls and implementing a robust maintenance program, you can significantly enhance the reliability and lifespan of your critical power infrastructure.

For more detailed information, please visit our official website:industrial generator set troubleshooting

About the author: Alex "Sparky" Johnson is a seasoned industrial power systems technician with over 15 years of hands-on experience in generator set maintenance, repair, and troubleshooting. He specializes in emergency power solutions for critical infrastructure and has a passion for demystifying complex technical subjects for a broader audience. Alex believes that proactive maintenance is the ultimate troubleshooting tool.