A power generator factory visit offers a unique opportunity to witness the intricate processes behind the creation of these essential machines. Whether you are a seasoned industry professional, a business owner seeking a reliable power solution, or an individual looking for a backup generator, understanding the manufacturing journey provides valuable insights. From raw materials to finished product, observing the stages of production, quality control measures, and technological advancements can significantly influence your purchasing decisions. So, what awaits you behind the doors of a modern power generator manufacturing facility?

Understanding the Manufacturing Process

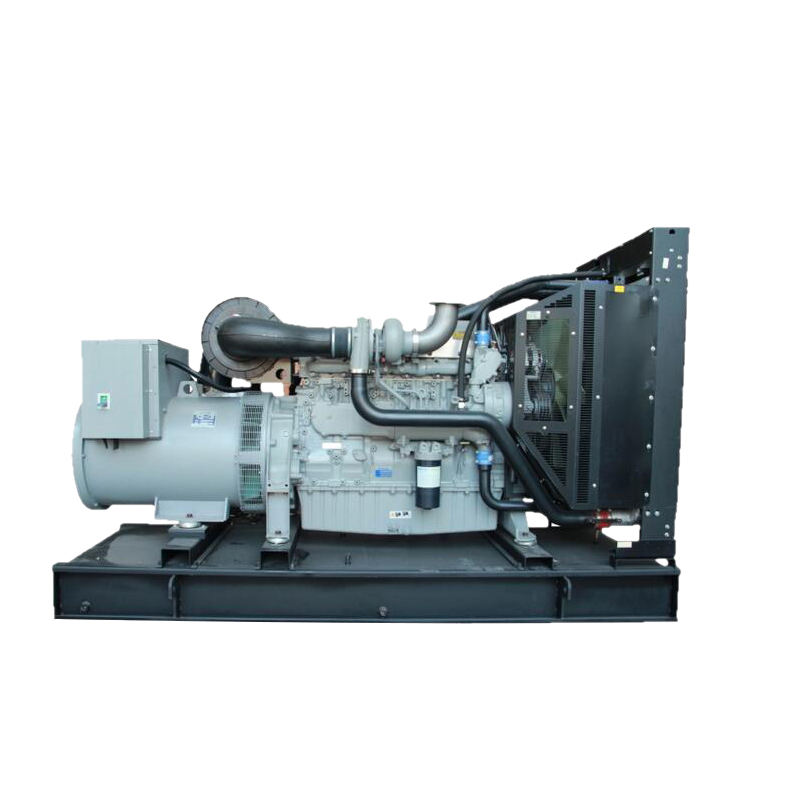

The journey of a power generator, such as the robust **HS10000 Generator**, begins with the careful selection of raw materials. Steel for the frame, copper for the windings, and high-quality components for the engine are all crucial. The manufacturing process then typically involves several key stages. First, the engine block is cast and machined to precise specifications. Next, the alternator, responsible for converting mechanical energy into electrical energy, is meticulously assembled. This involves winding copper coils, inserting them into the stator, and ensuring proper insulation. The frame is then fabricated, providing a sturdy housing for the engine and alternator. All components are tested individually before moving to the assembly line.

The assembly process is a carefully choreographed dance of precision and efficiency. Highly skilled technicians work along the assembly line, each responsible for a specific task. From attaching the engine to the frame to wiring the electrical components, every step is performed with meticulous attention to detail. Automated systems often play a key role, ensuring consistency and accuracy. Throughout the process, quality control checkpoints are strategically placed to identify and address any potential issues. This rigorous approach guarantees that each generator meets the highest standards of performance and reliability. But how do these quality checks actually work?

Quality Control and Testing

Quality control is paramount in power generator manufacturing. Our company employs a multi-layered approach to ensure that every generator leaving the factory meets stringent performance and safety standards. This starts with incoming material inspections, where raw materials are rigorously tested for compliance with specifications. Throughout the manufacturing process, in-process inspections are conducted to identify and address any defects early on. Once assembled, each generator undergoes a series of comprehensive tests. These include load testing, where the generator is subjected to varying electrical loads to ensure it can deliver the rated power. Vibration testing, insulation testing, and noise level measurements are also performed. Only generators that pass all these tests are deemed fit for shipment.

The importance of rigorous testing cannot be overstated. Power generators are often relied upon in critical situations, such as during power outages or in remote locations where grid electricity is unavailable. A faulty generator can have serious consequences, potentially leading to equipment damage or even endangering lives. Therefore, our commitment to quality control is unwavering. We are committed to providing reliable and durable power solutions for both our business partners looking for **industrial generator supplier** options and individual customers seeking a backup power source. Furthermore, all of our processes adhere to international standards, guaranteeing the reliability of our generators.

Exploring Advanced Manufacturing Technology

Modern power generator factories are equipped with cutting-edge technology to enhance efficiency, precision, and quality. Computer Numerical Control (CNC) machines are used for machining engine components and other critical parts to exacting tolerances. Robotic welding systems ensure consistent and strong welds on the frame and other structural elements. Automated assembly lines streamline the production process, minimizing human error and maximizing output. 3D printing technology is used for prototyping and creating custom parts. These advancements allow us to produce high-quality generators at a competitive cost. What kind of customization is possible with such advanced technology?

The integration of advanced manufacturing technologies allows for greater flexibility and customization. We can tailor generators to meet specific customer requirements, such as voltage, frequency, and power output. Custom paint colors and labeling are also available. Our engineering team works closely with customers to understand their needs and develop customized solutions. We also offer a range of optional features, such as automatic transfer switches (ATS) and remote monitoring systems. These technologies enhance the functionality and convenience of our generators, providing added value to our customers. We believe in providing options suitable for both business-scale **portable generator wholesale** and single unit purchases.

Witnessing the Power of the HS10000 Generator

Imagine standing before the assembly line, witnessing the birth of a robust power solution – the **HS10000 Generator**. This model is a prime example of the quality and innovation that goes into our generators. The HS10000 is designed to deliver reliable power for a wide range of applications, from construction sites and farms to homes and small businesses. Its key features include a powerful engine, a durable frame, and a user-friendly control panel. It boasts excellent fuel efficiency and low emissions, making it an environmentally responsible choice. With its robust construction and reliable performance, the HS10000 provides peace of mind in any situation. What makes the HS10000 stand out from the competition?

The HS10000 isn't just about raw power; it's about intelligent engineering. Its automatic voltage regulation (AVR) system ensures stable and consistent power output, protecting sensitive electronic equipment. The low oil shutdown feature prevents engine damage by automatically shutting down the generator if the oil level drops too low. The digital display provides real-time information on voltage, frequency, and runtime. These features, combined with its rugged construction and ease of use, make the HS10000 a top choice for both professionals and homeowners. It showcases our company's dedication to combining power with safety and ease of use. This commitment is evident in every generator we produce. Don't you want to see the HS10000 in action?

Customization and Large-Scale Supply Capabilities

One of the key advantages of visiting our factory is the opportunity to discuss customization options and explore our large-scale supply capabilities. We understand that different customers have different needs. That's why we offer a wide range of customization options, from minor adjustments to complete redesigns. Our experienced engineers are ready to work with you to develop a generator that meets your exact specifications. We also have the capacity to handle large-scale orders, thanks to our efficient production processes and extensive inventory of components. Whether you need a single customized generator or a thousand standard units, we can deliver. Our commitment to flexibility and scalability makes us a reliable partner for businesses of all sizes.

Our large-scale supply capabilities are supported by a robust supply chain and a team of experienced logistics professionals. We work closely with our suppliers to ensure a steady flow of high-quality materials. Our logistics team manages the entire shipping process, from packing and loading to customs clearance and delivery. We have a global network of distributors and service centers, ensuring that our generators are readily available and that customers receive timely support. We pride ourselves on our ability to deliver on our promises, providing our customers with the power they need, when they need it. We are a dependable **industrial generator supplier**, offering solutions that meet diverse requirements.

After-Sales Support and Service

Our commitment to our customers extends far beyond the sale. We provide comprehensive after-sales support and service to ensure that our generators perform reliably for years to come. Our technical support team is available to answer any questions and troubleshoot any issues. We also offer a range of service options, including preventive maintenance, repairs, and overhauls. Our network of certified service centers ensures that customers have access to qualified technicians who can provide expert assistance. We understand that downtime can be costly, so we strive to provide prompt and efficient service. Furthermore, we stock a wide range of spare parts to minimize repair times. This dedication to service gives our customers peace of mind, knowing that we are there to support them every step of the way.

Whether you require assistance with installation, operation, or maintenance, our team of experts is ready to help. We provide detailed manuals and training materials to ensure that you can operate your generator safely and efficiently. We also offer on-site training for larger installations. Our goal is to empower our customers to maximize the value of their generators and minimize the risk of downtime. This comprehensive approach to after-sales support is a testament to our commitment to customer satisfaction. After all, your peace of mind is our priority, ensuring that your **portable generator wholesale** or individual purchase is supported by comprehensive service.

A power generator factory visit offers a valuable glimpse into the world of power generation. From the meticulous selection of raw materials to the rigorous testing and quality control measures, every step of the manufacturing process is designed to ensure that our generators deliver reliable performance. Witnessing the production of the **HS10000 Generator** and understanding our customization and supply capabilities can help you make informed decisions and choose the right power solution for your needs. We invite you to experience the power of innovation and quality firsthand.

For more detailed information, please visit our official website: https://www.hsgeneratorset.com