In today's competitive landscape, ensuring the quality and reliability of your generator supply is paramount. A comprehensive generator factory audit provides invaluable insights into a manufacturer's capabilities, processes, and quality control measures. This article delves into the critical aspects of a generator factory audit, covering everything from production capacity to quality certifications, helping you make informed decisions whether you're a large corporation seeking a dependable supply of industrial generators or an individual looking for a reliable portable generator.

The Importance of a Generator Factory Audit

Why is a generator factory audit so important? Consider the potential consequences of receiving a substandard batch of generators: delayed projects, dissatisfied customers, damaged reputation, and potentially significant financial losses. An audit helps mitigate these risks by verifying a manufacturer's ability to consistently produce generators to the required specifications. It's not just about checking for compliance; it's about building confidence in a supplier's long-term capabilities and commitment to quality. Think of it as an insurance policy against costly setbacks, ensuring that your investment in generators delivers the performance and reliability you expect. This pre-emptive measure saves time, money, and resources in the long run by identifying potential issues before they escalate into major problems. A thorough audit will examine all stages of the manufacturing process, from raw material sourcing to final product testing. This detailed inspection provides a holistic view of the factory's operations and identifies areas for improvement.

Key Areas Covered in a Generator Factory Audit

A comprehensive generator factory audit covers a wide range of areas, each contributing to the overall assessment of the manufacturer. Here are some key aspects that are typically examined:

- Production Capacity and Scale: Assessing the manufacturer's ability to meet your specific volume requirements, both now and in the future.

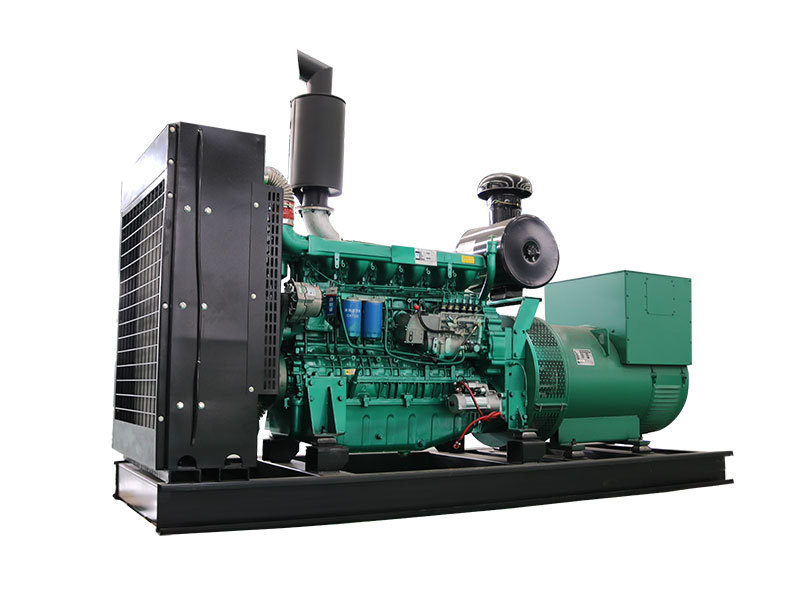

- Manufacturing Equipment and Facilities: Evaluating the condition and modernity of the equipment used in production, ensuring it meets industry standards.

- Quality Control Processes: Examining the procedures in place to monitor and control quality throughout the manufacturing process, including incoming material inspection, in-process inspection, and final product testing.

- Technical Capabilities and Expertise: Assessing the manufacturer's engineering and technical expertise, including their ability to design and develop new generator models.

- Certifications and Compliance: Verifying that the manufacturer holds the necessary certifications and complies with relevant industry standards and regulations.

- Supplier Management: Understanding how the manufacturer manages its own supply chain to ensure the quality and consistency of raw materials and components.

These are just some of the essential elements covered in a typical factory audit. The specific scope of the audit can be tailored to your particular needs and requirements. For example, if you're interested in a specific product like the **HS10000 Generator Model**, the audit can focus on the manufacturing processes and quality control measures specific to that model.

Production Capacity and Scale: Meeting Your Demand

One of the first things a factory audit will assess is the manufacturer's production capacity. Can they handle your order volume? Are they equipped to scale up production if your needs increase in the future? This assessment involves analyzing the factory's equipment, workforce, and production processes to determine its maximum output. It also considers the manufacturer's ability to manage lead times and maintain a stable supply of generators, even during periods of high demand. Understanding the manufacturer's capacity allows you to plan your own operations more effectively and avoid potential supply chain disruptions. A detailed evaluation includes verifying the number of production lines, the number of workers, and the efficiency of the manufacturing processes. The auditors will also assess the manufacturer's ability to manage inventory and logistics, ensuring they can deliver generators on time and to the specified location.

Advanced Manufacturing Equipment and Facilities

The quality of the manufacturing equipment and facilities is a direct indicator of the manufacturer's commitment to quality and efficiency. Are they using modern, well-maintained equipment? Do they have the necessary infrastructure to support their production processes? A factory audit will examine the condition of the machinery, the layout of the factory, and the overall cleanliness and organization of the workspace. Modern equipment not only improves production efficiency but also enhances the precision and consistency of the manufacturing process, leading to higher-quality generators. For example, automated welding machines can produce more consistent welds than manual welding, reducing the risk of defects. Regular maintenance and calibration of equipment are also crucial to ensure accuracy and reliability. This section of the audit assesses whether the factory has a robust maintenance program in place and whether they adhere to industry best practices for equipment management. The use of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems also showcases the manufacturer's investment in technology and their ability to produce complex generator designs with precision.

Quality Control Processes: Ensuring Consistent Quality

Robust quality control processes are the cornerstone of any reliable generator manufacturer. A thorough factory audit will scrutinize every stage of the manufacturing process, from incoming material inspection to final product testing. This includes evaluating the procedures for identifying and addressing defects, the training of quality control personnel, and the documentation of quality control data. A key aspect of quality control is traceability. Can the manufacturer trace each component back to its source? This allows them to quickly identify and isolate the root cause of any quality issues. Furthermore, the audit assesses the manufacturer's use of statistical process control (SPC) techniques to monitor and improve the manufacturing process. SPC helps identify trends and patterns that can lead to defects, allowing the manufacturer to take corrective action before problems arise. By verifying the effectiveness of the quality control processes, the audit provides assurance that the generators are manufactured to the highest standards.

Technical Capabilities and Expertise: Innovation and Customization

A manufacturer's technical capabilities and expertise are crucial for ensuring they can meet your specific requirements and adapt to changing market demands. This includes assessing their engineering team's experience and qualifications, their ability to design and develop new generator models, and their capacity to provide technical support. Can they offer customization options to tailor generators to your unique needs? Do they have the expertise to troubleshoot and resolve technical issues quickly and efficiently? A factory audit will evaluate the manufacturer's research and development (R&D) capabilities, their investment in new technologies, and their ability to innovate. This section of the audit also considers the manufacturer's understanding of relevant industry standards and regulations. Are they familiar with the latest emission standards? Can they ensure that their generators comply with all applicable safety requirements? A strong technical foundation enables the manufacturer to produce high-quality, reliable generators that meet the evolving needs of their customers. It also ensures they can provide ongoing technical support and assistance throughout the product lifecycle.

Certifications and Compliance: Meeting Industry Standards

Certifications and compliance are essential for demonstrating a manufacturer's commitment to quality, safety, and environmental responsibility. A factory audit will verify that the manufacturer holds the necessary certifications, such as ISO 9001 (quality management), ISO 14001 (environmental management), and OHSAS 18001 (occupational health and safety). These certifications demonstrate that the manufacturer has implemented robust management systems and adheres to industry best practices. The audit will also assess the manufacturer's compliance with relevant industry standards and regulations, such as those related to emissions, noise levels, and electrical safety. Compliance with these standards ensures that the generators meet the required performance and safety criteria. For example, the **HS10000 Generator Model** and others may be subject to specific emission regulations in certain regions. The audit will verify that the manufacturer has taken the necessary steps to ensure compliance with these regulations. By verifying certifications and compliance, the audit provides assurance that the generators are manufactured to the highest standards and meet all applicable requirements.

Supplier Management: Ensuring Quality Components

The quality of a generator is only as good as the quality of its components. A factory audit will examine how the manufacturer manages its own supply chain to ensure the quality and consistency of raw materials and components. This includes evaluating their supplier selection process, their supplier quality control procedures, and their relationships with key suppliers. Do they have long-term partnerships with reputable suppliers? Do they conduct regular audits of their suppliers' facilities? The audit will also assess the manufacturer's ability to track and trace components throughout the supply chain. This allows them to quickly identify and isolate any quality issues that may arise. A robust supplier management program ensures that the manufacturer receives high-quality components from reliable sources, minimizing the risk of defects and ensuring the overall reliability of the generators. For example, if a particular batch of engines is found to be defective, the manufacturer should be able to quickly identify the supplier and the affected generators.

Flexibility for Business and Individual Purchases: Meeting Diverse Needs

Whether you're a large business seeking to purchase generators in bulk or an individual looking for a reliable portable generator like the **HS3000 Generator Model**, the manufacturer should be able to accommodate your needs. A factory audit will assess their ability to handle both large and small orders, their flexibility in terms of customization options, and their responsiveness to customer inquiries. Can they provide samples for testing and evaluation? Do they offer flexible payment terms? The audit will also evaluate the manufacturer's customer service capabilities. Do they have a dedicated customer service team to handle inquiries and resolve issues? Do they provide after-sales support, such as maintenance and repair services? A manufacturer that is flexible and responsive to customer needs is more likely to build long-term relationships and provide a positive customer experience. This adaptability is crucial in today’s dynamic market, where customer needs and expectations are constantly evolving.

After-Sales Support and Services: Long-Term Partnership

A strong manufacturer provides comprehensive after-sales support and services to ensure the long-term performance and reliability of their generators. This includes offering maintenance and repair services, providing spare parts, and offering technical support. A factory audit will assess the manufacturer's after-sales service capabilities, including the size and experience of their service team, their availability of spare parts, and their responsiveness to customer requests. Do they offer warranty coverage? Do they have a network of authorized service centers? The audit will also evaluate the manufacturer's training programs for technicians and operators. Proper training ensures that the generators are operated and maintained correctly, maximizing their lifespan and minimizing the risk of breakdowns. A commitment to after-sales support demonstrates a manufacturer's dedication to their customers and their confidence in the quality of their products. It fosters long-term relationships and provides peace of mind knowing that help is available when needed.

Conclusion: Choosing the Right Generator Supplier

A generator factory audit is a critical step in selecting a reliable supplier and ensuring the quality of your generator investment. By thoroughly assessing a manufacturer's capabilities, processes, and quality control measures, you can mitigate risks and build confidence in their ability to consistently produce high-quality generators. Whether you're seeking a robust industrial generator or a dependable portable model like the **HS5000 Generator Model**, a factory audit provides valuable insights that can help you make informed decisions. Remember to consider all aspects of the audit, from production capacity and equipment to quality control processes and after-sales support. By choosing a manufacturer that meets your specific requirements and demonstrates a commitment to quality, you can ensure a reliable and long-lasting supply of generators. For businesses looking to minimize risks and for individuals searching for quality and value, conducting or commissioning a generator factory audit can prove to be an excellent investment, ultimately ensuring satisfaction and reliability with your generator purchases.

For more detailed information, please visit our official website: https://www.hsgeneratorset.com

`