Don\'t Let the Lights Go Out: The Ultimate Guide to Power Outage Solutions for Factories

Have you ever stopped to calculate the true cost of just one hour of downtime in your facility? It's a sobering thought. In the world of manufacturing, a steady, uninterrupted flow of power isn't a luxury; it's the lifeblood of your entire operation. A sudden power outage can bring everything to a grinding halt, triggering a cascade of problems that extend far beyond a silent production floor. Frankly speaking, relying solely on the public grid in today's world is a high-stakes gamble. That's why implementing robust power outage solutions for factories is one of the most critical investments a modern industrial facility can make.

From precision CNC machines to automated assembly lines and critical data servers, every component of your operation depends on electricity. This guide will walk you through the essential strategies and technologies to ensure that when the grid fails, your factory doesn't.

The Staggering Cost of a Single Power Outage

It's easy to underestimate the impact of a blackout. You might think it's just a matter of lost production time, but the reality is far more complex and costly. The financial repercussions can be staggering, and understanding them is the first step toward justifying a proper backup power strategy.

Beyond Lost Production: The Hidden Costs

The most obvious cost is, of course, the value of the goods you didn't produce. But let's dig deeper. In my experience, the hidden costs are what truly cripple a business:

- Equipment Damage: An abrupt shutdown or a power surge when the grid returns can wreak havoc on sensitive electronics, motors, and control systems. The cost of repairing or replacing a multi-million dollar piece of machinery can dwarf the cost of lost production.

- Wasted Materials: What happens to the batch of product that was halfway through a heating, cooling, or chemical process when the power cut out? Often, it's a total loss. This raw material and work-in-progress spoilage adds up incredibly fast.

- Labor Costs: Your workforce is on the clock, but they can't work. You're paying for idle time, which directly impacts your bottom line.

- Supply Chain Disruption: A delay at your factory creates a domino effect. Your failure to deliver on time can lead to penalties, strained client relationships, and a damaged reputation that can take years to rebuild.

- Data Loss and System Reboots: It can take hours to safely reboot complex IT systems, control networks, and production machinery. In the process, critical production data might be corrupted or lost entirely.

Why Grid Reliability is a Growing Concern

To be honest, the electrical grid isn't as reliable as it used to be. Several factors are contributing to this increased vulnerability. Aging infrastructure across the country is struggling to keep up with modern demands. Furthermore, the increasing frequency of extreme weather events—from hurricanes and ice storms to heatwaves—puts immense strain on the system. Add to that the ever-growing demand for electricity, and you have a perfect storm for more frequent and longer-lasting outages.

Your First Line of Defense: Industrial Backup Power Systems

When the grid goes down, you need a reliable source of power ready to take over instantly. This is where industrial backup power systems come into play. These aren't just small generators you'd buy at a hardware store; they are heavy-duty, engineered solutions designed to power a large-scale facility. The two primary components of a robust system are generators and an Uninterruptible Power Supply (UPS).

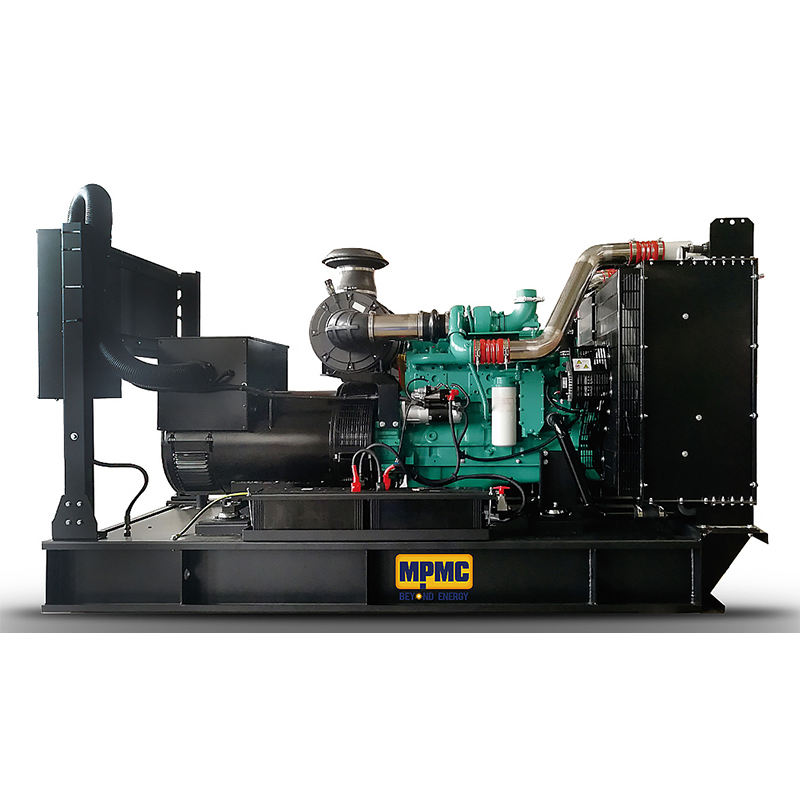

The Workhorse: Industrial Generators

An industrial generator is the backbone of any serious backup power plan. It’s an engine that can run on various fuels to generate electricity for your entire facility, or at least its most critical loads. The main types include:

- Diesel Generators: These are the most common choice for factories due to their reliability, longevity, and ability to handle large electrical loads. They start quickly and can run for days or even weeks as long as you have fuel.

- Natural Gas Generators: A cleaner-burning option that connects directly to your facility's natural gas line. This eliminates the need for on-site fuel storage but makes you dependent on the gas utility during a widespread disaster.

- Propane Generators: Similar to natural gas but uses stored liquid propane. It's a clean fuel with a long shelf life, making it a reliable choice.

The key is to size the generator correctly to meet your factory's specific load requirements. It's worth noting that regular maintenance and fuel management are absolutely non-negotiable for ensuring reliability.

The Instant Guardian: Uninterruptible Power Supply (UPS)

A generator is powerful, but it's not instantaneous. It can take anywhere from 10 to 60 seconds to detect an outage, start up, and begin supplying power. For your sensitive electronics—like servers, computer-controlled machinery, and safety systems—even a one-second gap can be catastrophic. This is where a UPS saves the day.

A UPS is essentially a large battery system that provides immediate, seamless power the millisecond the grid fails. It acts as a bridge, keeping your critical systems online until the generator takes over. For less critical systems, it provides enough time for a safe, orderly shutdown, preventing data corruption and equipment damage. Many experts agree that a combination of a UPS for critical loads and a generator for long-term power is the gold standard for factory resilience.

Building a Resilient Power Strategy: Beyond the Basics

Simply buying a generator and a UPS isn't enough. A truly effective strategy involves integrating these components into a smart, automated system. This is a core tenet of preventing downtime in manufacturing. You need the right supporting hardware and a clear plan to manage the transition from grid to backup power seamlessly.

Automatic Transfer Switches (ATS): The Unsung Hero

How does your factory switch from grid power to generator power? You certainly don't want an employee fumbling with massive cables in the dark. An Automatic Transfer Switch (ATS) is the brain of your backup system. It constantly monitors the incoming utility power. The moment it detects a failure, it automatically disconnects your facility from the grid and signals the generator to start. Once the generator is ready, the ATS safely switches your factory's electrical load over to it. When grid power is restored and stable, it switches everything back. It’s a crucial component for a safe, fast, and hands-off transition.

Power Monitoring and Management Systems

Modern power systems can be equipped with sophisticated monitoring technology. These systems give you a real-time view of your power quality, energy consumption, and the status of your backup equipment. They can alert you to potential problems before they cause an outage, help you manage electrical loads during a blackout (a process called load shedding), and provide valuable data to optimize your energy efficiency. Interestingly enough, this data can often help identify cost-saving opportunities during normal operation, too.

Proactive Measures: The Best Solution is Prevention

While having powerful backup hardware is essential, the most effective power outage solutions for factories often begin with planning and proactive maintenance. A reactive approach is always more expensive and stressful than a proactive one.

The Critical Role of a Power Outage Contingency Plan

What happens when the lights go out? Who does what? A detailed contingency plan answers these questions before a crisis hits. This written document should be accessible to all key personnel and should outline:

- Communication Protocols: How will you inform employees, suppliers, and customers? Who is the point person for communication?

- Shutdown Procedures: A step-by-step guide for safely shutting down non-critical machinery to conserve backup power.

- Roles and Responsibilities: Clearly define who is responsible for overseeing the backup systems, who manages safety protocols, and who coordinates with utility companies.

- Contact Information: A list of emergency contacts, including your generator service company, fuel supplier, and electrical contractor.

Regular Maintenance and Testing: Don't Wait for a Crisis

I've found that this is the most frequently overlooked aspect of power preparedness. Your backup power system is like a life raft—you need to know it will work when you need it most. An untested generator is little more than a very expensive piece of metal. A comprehensive maintenance program should include:

- Weekly Visual Inspections: Check for leaks, loose connections, and clear any debris around the equipment.

- Monthly No-Load Tests: Start the generator without transferring the load to ensure the engine runs properly.

- Quarterly or Annual Load Bank Tests: This is a critical test where you run the generator under a simulated load to ensure it can perform at its full rated capacity. It also helps clean out engine deposits.

- UPS Battery Checks: Batteries have a finite lifespan. They must be regularly tested and replaced according to the manufacturer's schedule.

Scheduling this with a qualified service provider ensures your investment is ready to perform flawlessly when called upon.

Choosing the Right Power Outage Solutions for Your Factory

Every factory is unique, with different power needs, operational priorities, and budgets. There is no one-size-fits-all solution. Selecting the right system requires a careful and methodical approach.

Conducting a Power Needs Assessment

The first step is to understand exactly what you need to power. This involves a thorough audit of your electrical loads. You’ll need to categorize them:

- Critical Loads: These are the absolute essentials that must remain on at all costs. This includes servers, safety systems, core production machinery, and basic lighting.

- Important Loads: These are systems that you need to run the business but could potentially be shut down for short periods, such as HVAC in non-critical areas.

- Non-Essential Loads: These can be shut down during an outage to conserve fuel and reduce the required size of your generator.

Once you know your critical load, you can determine the required size (in kilowatts) of your generator and UPS. You also need to decide on the required runtime. Do you need to bridge an hour-long outage, or do you need to be prepared to operate for several days?

Factoring in Budget, Space, and Regulations

Of course, practical considerations will play a major role. The initial purchase price is just one part of the total cost of ownership. You must also budget for installation, commissioning, fuel, ongoing maintenance, and potential repairs. You'll also need to consider physical space for the equipment, as well as local regulations regarding noise, emissions, and fuel storage.

Ultimately, finding the perfect balance between capability and cost is key. Investing in a comprehensive strategy is not an expense; it's an insurance policy against catastrophic financial loss. The right power outage solutions for factories pay for themselves the very first time they're needed, protecting your assets, your reputation, and your profitability for years to come.

For more detailed information, please visit our official website:power outage solutions for factories

About the author: David Chen is an Industrial Power Solutions Consultant with over 15 years of experience helping manufacturing facilities design and implement resilient backup power systems. He specializes in conducting critical load assessments and integrating generator, UPS, and ATS technologies to eliminate downtime. David is passionate about helping businesses protect their operations from the growing threat of grid instability and has been featured in several industry publications for his practical, no-nonsense approach to power security.