Unlock Reliable Power: Your Guide to Requesting a Quote for a Custom Generator Set

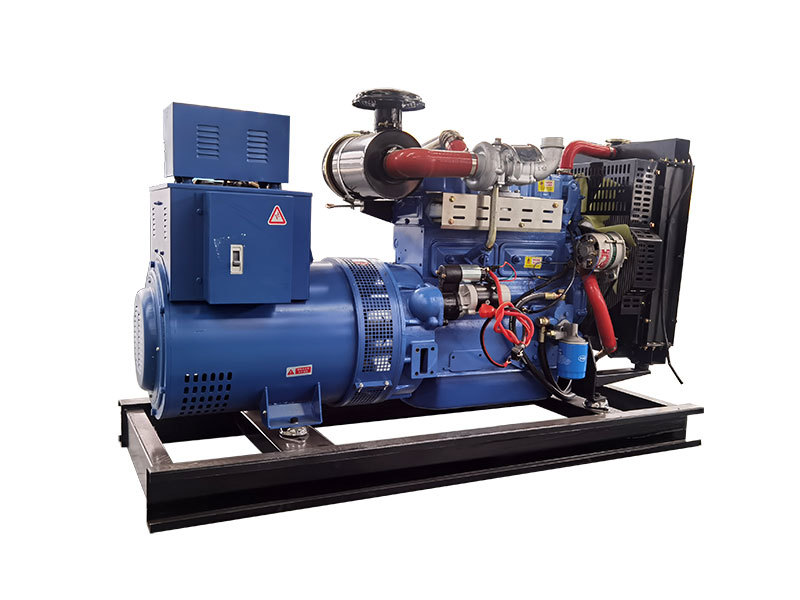

In today's world, reliable power isn't just a convenience; it's a necessity. Whether you're running a critical industrial operation, ensuring business continuity during outages, or powering a remote site, a generator set is often the backbone of your operations. But what happens when standard, off-the-shelf solutions just don't cut it? That's where custom generator sets come in. When you need a power solution tailored precisely to your unique demands, the process of how to request quote for custom generator set becomes paramount. It's not as simple as picking a model off a shelf; it requires careful consideration and clear communication.

Frankly speaking, investing in a custom generator set is a significant decision. It's about ensuring you have the right power, at the right time, and with the right features to support your specific needs. Many businesses and organizations find themselves in situations where their power requirements are complex, involving specific fuel types, environmental considerations, noise restrictions, or integration with existing infrastructure. In these scenarios, a standard generator simply won't suffice. This guide will walk you through everything you need to know to effectively request quote for custom generator set, ensuring you get a solution that’s not only powerful but also perfectly suited to your operational landscape.

Understanding Your Power Needs: The Foundation of a Custom Generator Set

Before you even think about reaching out for a quote, the most crucial step is a thorough assessment of your power requirements. This isn't a task to be rushed. In my experience, a lack of clarity here is the most common reason for delays or dissatisfaction with custom solutions. You need to define precisely what you need the generator set to do.

Determining Power Capacity (kW/kVA)

This is the most fundamental aspect. What is the total load you need to power? Think about all the equipment, machinery, lighting, and HVAC systems that will be connected. It’s wise to calculate the running load and the starting load. Starting a motor, for instance, can draw significantly more power than its continuous running requirement. Overestimating slightly is often better than underestimating, as an undersized generator can lead to frequent shutdowns and potential damage.

Fuel Type Considerations

The type of fuel available and preferred is a major factor.

- Diesel: The most common choice for industrial applications due to its reliability, power density, and widespread availability.

- Natural Gas: Often more cost-effective for fuel and cleaner burning, but requires a reliable natural gas supply.

- Propane (LPG): A good option for sites without natural gas access, offering cleaner emissions than diesel.

- Bi-Fuel/Dual Fuel: These systems can run on a combination of fuels, offering flexibility and redundancy.

The choice of fuel will impact the generator's design, efficiency, and ongoing operating costs.

Environmental and Site-Specific Factors

Where will the generator be located? This is critically important for custom builds.

- Noise Levels: Are there strict noise ordinances or sensitive neighbors? This will dictate the need for sound-attenuated enclosures.

- Climate: Extreme temperatures (hot or cold), humidity, or corrosive environments can affect generator performance and require specific cooling systems or protective coatings.

- Space Constraints: The physical dimensions of the generator set and its enclosure need to fit within the allocated space.

- Ventilation and Exhaust: Proper ventilation is essential for cooling, and exhaust systems need to be safely routed away from occupied areas.

Duty Cycle and Backup Requirements

Will the generator be used for prime power (continuous operation), standby power (backup during outages), or peak shaving (reducing demand charges)? The intended duty cycle will influence the design and durability requirements. For standby applications, you'll also need to consider the required response time.

What to Include When You Request a Quote for Custom Generator Set

Once you have a clear understanding of your needs, it’s time to prepare the information you’ll provide to potential suppliers. The more detailed and accurate your request, the more precise and relevant the quotes you will receive. To effectively request quote for custom generator set, you need to be prepared to share specific details.

Detailed Specifications Sheet

This is your primary document. It should include everything you've identified in the needs assessment phase.

- Power Output: Continuous kW, Standby kW, Voltage, Phase, Frequency (Hz).

- Engine Details: Preferred manufacturer (if any), engine type, emissions standards (e.g., EPA Tier 4).

- Alternator Details: Type, voltage regulation, efficiency.

- Fuel System: Type, tank capacity (if integrated), fuel consumption at various load levels.

- Cooling System: Radiator type, fan size, ambient temperature rating.

- Exhaust System: Silencer type, exhaust pipe diameter, material.

- Control System: Automatic Transfer Switch (ATS) compatibility, remote monitoring capabilities, specific control panel features (e.g., digital display, data logging).

- Enclosure Requirements: Sound attenuation level (dB rating), weather protection (IP rating), material, access doors, lifting points.

- Mounting: Skid-mounted, trailer-mounted, or foundation requirements.

Application Context

Explain *why* you need the generator.

- What industry are you in?

- What is the primary function of the generator (e.g., critical facility backup, remote site power, temporary construction power)?

- Are there any specific industry standards or regulations that must be met?

Budgetary Considerations

While you might not want to disclose your absolute maximum budget, providing a general range can help suppliers propose solutions that are financially viable for you. It’s worth noting that custom solutions often come with a higher upfront cost than standard models, but the long-term benefits in reliability and performance can outweigh this.

Timeline and Delivery Requirements

When do you need the generator set? Are there specific installation deadlines or site access limitations that need to be considered for delivery?

Existing Infrastructure and Integration

If the generator set needs to integrate with existing electrical systems, provide details about your current setup, including switchgear, ATS, and any building management systems.

Navigating the Quote Process: Key Considerations and Questions

Once you've submitted your detailed request, you'll likely receive quotes from several suppliers. Now comes the critical part: evaluating these proposals. It’s not just about the lowest price. To be honest, focusing solely on cost can lead to significant problems down the line.

Evaluating Supplier Reputation and Experience

Look beyond the numbers.

- Track Record: How long has the supplier been in business? Do they specialize in custom solutions?

- References: Ask for client references, especially for projects similar to yours.

- Technical Expertise: Do their engineers seem knowledgeable and capable of handling your complex requirements?

- After-Sales Support: What kind of warranty is offered? What are their service and maintenance capabilities? Availability of spare parts is also crucial.

Understanding the Quote Details

Don't skim over the fine print.

- Inclusions and Exclusions: What exactly is included in the price? Are installation, commissioning, testing, and training part of the package?

- Lead Times: Confirm the estimated manufacturing and delivery schedule.

- Payment Terms: Understand the deposit requirements, progress payments, and final payment schedule.

- Warranty: What is covered, for how long, and under what conditions?

- Compliance: Ensure the quote explicitly states compliance with any relevant standards or regulations you specified.

Asking the Right Questions

Have engaging questions ready for the suppliers.

- "Can you provide a detailed breakdown of the cost components, including engineering, manufacturing, and testing?"

- "What are the projected fuel consumption rates at 50%, 75%, and 100% load?"

- "What is your process for factory acceptance testing (FAT) and site acceptance testing (SAT)?"

- "How do you handle unforeseen technical challenges during the manufacturing process?"

- "What are the options for remote monitoring and diagnostics?"

Interestingly enough, the way a supplier answers these questions can reveal a lot about their professionalism and commitment to quality.

The Benefits of a Custom Generator Set and Why It's Worth the Investment

Opting for a custom generator set is an investment, and like any significant investment, it's important to understand the return. When you decide to request quote for custom generator set, you're not just buying a piece of equipment; you're investing in tailored reliability and operational efficiency.

Optimized Performance

Custom-built units are designed to meet your exact power demands, ensuring optimal efficiency and minimizing waste. They are engineered to operate at peak performance within your specific environmental conditions and load profiles.

Enhanced Reliability

By selecting high-quality components and integrating them precisely for your application, custom generators offer superior reliability. This is crucial for critical operations where downtime can be incredibly costly.

Long-Term Cost Savings

While the upfront cost might be higher, a custom generator set can lead to significant long-term savings. This comes from improved fuel efficiency, reduced maintenance needs due to appropriate component selection, and the avoidance of costly downtime and potential equipment damage that can result from using an undersized or unsuitable standard unit.

Compliance and Safety

Custom solutions can be engineered to meet stringent industry-specific regulations, environmental standards, and safety requirements that off-the-shelf models might not satisfy. This peace of mind is invaluable.

Flexibility and Scalability

A well-designed custom generator can sometimes be engineered with future expansion in mind, offering a degree of scalability that might not be possible with standard units.

In conclusion, when the need arises for a power solution that goes beyond the ordinary, knowing how to effectively request quote for custom generator set is key. It’s a process that demands diligence, clear communication, and a thorough understanding of your own operational needs. By following the steps outlined in this guide, you can ensure you partner with the right supplier and secure a custom generator set that provides the reliable, efficient, and tailored power you need to succeed.

For more detailed information, please visit our official website:custom generator set quote

About the author: An expert in industrial power solutions with over 15 years of experience, Alex Chen specializes in designing and implementing bespoke generator systems for a wide range of industries. His practical insights stem from hands-on project management and a deep understanding of electrical engineering principles. Alex is passionate about helping businesses achieve uninterrupted power and operational excellence through intelligent power generation strategies.