Unlocking Reliability: A Deep Dive into Industrial Generator Set Failure Analysis

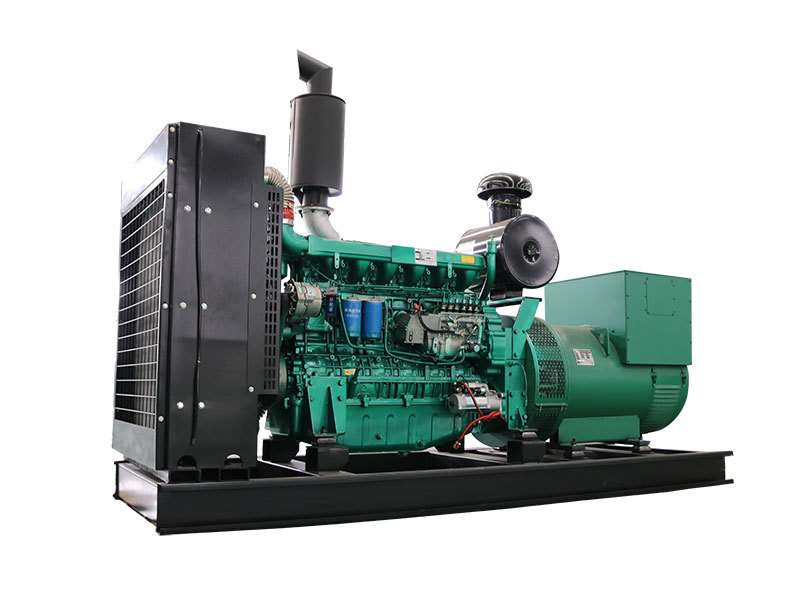

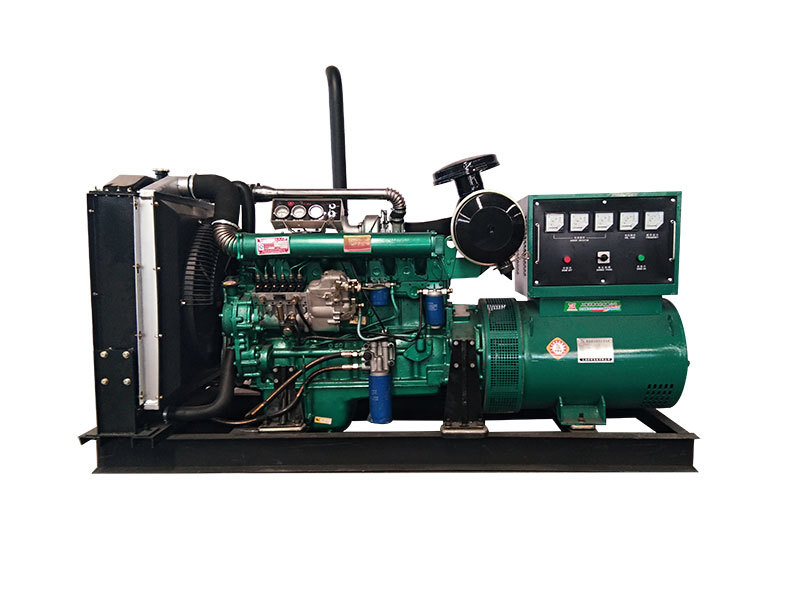

Industrial generator sets are the unsung heroes of modern infrastructure. From hospitals and data centers to manufacturing plants and remote construction sites, they provide the crucial backup power needed to keep operations running smoothly when the grid falters. But what happens when these vital machines fail? Understanding and performing thorough industrial generator set failure analysis is paramount to ensuring uptime, preventing costly disruptions, and safeguarding critical assets. Frankly speaking, a generator failure isn't just an inconvenience; it can be a catastrophe.

In my experience, many organizations treat generator maintenance as a reactive measure, only addressing issues when they arise. This approach is often more expensive and disruptive than a proactive strategy. This article aims to equip you with the knowledge to understand why generators fail, how to diagnose problems effectively, and what steps to take to prevent future failures. We'll delve into the common culprits behind generator malfunctions and explore the systematic approach required for robust industrial generator set failure analysis.

Common Causes of Industrial Generator Set Failures

The complexity of an industrial generator set means there are numerous potential points of failure. These can range from simple mechanical issues to intricate electrical problems. To effectively conduct a failure analysis, it's essential to categorize these causes.

Fuel System Issues

The fuel system is the lifeblood of any internal combustion engine, and generators are no exception. Problems here are surprisingly common.

- Contaminated Fuel: Water, dirt, or microbial growth in the fuel can clog filters, injectors, and fuel lines, leading to rough running or complete shutdown. Regular fuel testing and proper storage are key preventative measures.

- Fuel Pump Malfunctions: A failing fuel pump won't deliver adequate fuel pressure, starving the engine.

- Injector Problems: Clogged or worn injectors can cause uneven combustion, power loss, and increased emissions.

- Fuel Line Leaks: These pose a safety hazard and can lead to air entering the system, disrupting fuel flow.

Lubrication System Failures

Proper lubrication is critical for reducing friction and wear within the engine.

- Low Oil Levels: Insufficient oil can lead to overheating and severe internal engine damage.

- Oil Contamination: Coolant or fuel leaks into the oil can degrade its lubricating properties.

- Oil Filter Clogging: A blocked filter restricts oil flow, starving vital engine components.

- Oil Pump Failure: Similar to the fuel pump, a failing oil pump means no lubrication.

Cooling System Problems

Generators produce a significant amount of heat, and an effective cooling system is vital for preventing overheating.

- Low Coolant Levels: Leaks or evaporation can lead to insufficient coolant, causing the engine to overheat.

- Radiator Blockages: Debris or internal corrosion can impede coolant flow.

- Thermostat Malfunctions: A stuck thermostat can prevent the engine from reaching its optimal operating temperature or cause it to overheat.

- Fan Belt Issues: A broken or slipping fan belt means the radiator cannot dissipate heat effectively.

Electrical System Faults

The electrical components are where the generator’s output is generated and controlled. Failures here can be complex.

- Alternator Issues: Worn bearings, damaged windings, or regulator problems can lead to no output or unstable voltage.

- Control Panel Malfunctions: Faulty sensors, relays, or circuit boards can prevent the generator from starting, running, or transferring load.

- Battery Problems: A weak or dead battery is a frequent cause of failure to start.

- Wiring and Connection Issues: Loose or corroded connections can cause intermittent operation or complete failure.

Exhaust System Blockages

A restricted exhaust can cause backpressure, reducing engine efficiency and potentially leading to damage.

- Carbon Buildup: Incomplete combustion can lead to soot accumulation in the exhaust manifold or muffler.

- Damaged Muffler: Internal baffles can break loose and obstruct exhaust flow.

- Exhaust Leaks: While not always a cause of failure, they can be a symptom of other issues and pose a safety risk.

Diagnostic Techniques for Industrial Generator Set Failure Analysis

When a generator fails, a systematic diagnostic approach is crucial. It’s not about guessing; it’s about methodical elimination.

Initial Checks and Visual Inspection

Before diving into complex diagnostics, start with the basics.

- Check Fuel Levels: Seems obvious, but it's often overlooked.

- Inspect for Leaks: Look for any signs of fuel, oil, or coolant leaks around the engine and connections.

- Examine Belts and Hoses: Ensure they are taut, free from cracks, and securely fastened.

- Check Battery Terminals: Look for corrosion and ensure connections are tight.

- Listen for Unusual Noises: Grinding, knocking, or excessive rattling can indicate mechanical problems.

Using Diagnostic Tools

Modern generators often have built-in diagnostic systems, but external tools are invaluable.

- Multimeter: Essential for checking voltage, resistance, and continuity in electrical circuits.

- Scan Tools: For electronically controlled generators, these can read fault codes directly from the engine control unit (ECU).

- Fuel Pressure Gauge: To verify that the fuel system is delivering the correct pressure.

- Compression Tester: To assess the health of the engine's cylinders.

- Infrared Thermometer: Useful for identifying hot spots that could indicate electrical issues or uneven combustion.

Interpreting Fault Codes

Many generators store diagnostic trouble codes (DTCs) when a fault occurs. Understanding these codes is a critical part of industrial generator set failure analysis. These codes can point directly to the problematic system or component, saving significant troubleshooting time. It’s worth noting that the meaning of codes can vary between manufacturers, so always refer to the generator’s service manual. Have you ever wondered how those complex fault codes actually help pinpoint a problem? It’s like a secret language that technicians learn to decipher!

Load Testing

Sometimes, a generator might start and run fine under no load but fail when the actual load is applied. A load bank test simulates real-world operating conditions and can reveal issues related to power output, voltage regulation, and engine performance under stress. This is particularly important for generators that are infrequently used.

Preventative Maintenance Strategies

The most effective way to deal with generator failures is to prevent them from happening in the first place. A robust preventative maintenance program is non-negotiable for critical power systems.

Regular Inspections and Servicing

Follow the manufacturer's recommended service schedule religiously. This typically includes:

- Oil and Filter Changes: At specified intervals.

- Coolant Checks and Flushes: Ensuring the correct coolant mixture and replacing it periodically.

- Fuel System Cleaning and Testing: Including fuel polishing and filter replacement.

- Battery Maintenance: Checking voltage, specific gravity, and terminal cleanliness.

- Inspection of Exhaust and Air Intake Systems: For blockages or damage.

Load Exercise

As mentioned, generators need to be exercised regularly, ideally under load. This helps to:

- Keep internal components lubricated and free from corrosion.

- Burn off any moisture or carbon deposits that may have accumulated.

- Ensure the automatic transfer switch (ATS) functions correctly.

- Familiarize operators with the startup and shutdown procedures.

Fuel Management

Fuel quality is often underestimated. Implementing a proactive fuel management strategy can prevent a host of problems. This includes:

- Regular fuel testing for water and microbial contamination.

- Using fuel additives if necessary.

- Implementing a fuel polishing system for long-term storage.

- Ensuring proper fuel tank venting and maintenance to prevent condensation.

Advanced Failure Analysis and Root Cause Identification

When a critical failure occurs, a superficial fix isn't enough. A deep dive into industrial generator set failure analysis is required to identify the root cause and prevent recurrence. This often involves more advanced techniques.

Component Failure Analysis

For recurring or severe failures, individual components may need to be sent for metallurgical or material analysis. This can reveal manufacturing defects, material fatigue, or improper installation that might not be apparent through standard diagnostics.

Data Logging and Trend Analysis

Many modern generator control systems can log operational data over time. Analyzing this data can reveal subtle trends or anomalies that precede a failure. For instance, a gradual increase in exhaust gas temperature or a slight drop in oil pressure might be early indicators of an impending problem. Many experts agree that proactive monitoring is key.

Failure Mode and Effects Analysis (FMEA)

While often used in the design phase, FMEA can also be applied retrospectively to understand how a system failure occurred and what the consequences were. This systematic approach helps in identifying potential failure modes, their causes, and their effects, leading to more robust preventative measures.

Root Cause Analysis (RCA) Methodologies

Techniques like the "5 Whys" or Ishikawa (fishbone) diagrams can be invaluable in moving beyond the immediate cause of a failure to uncover the underlying systemic issues. For example, if an engine fails due to overheating, the immediate cause is the cooling system. But *why* did the cooling system fail? Perhaps it was a lack of maintenance. *Why* was there a lack of maintenance? Perhaps the maintenance schedule wasn't clear, or staff were not adequately trained. This iterative questioning helps peel back the layers.

Interestly enough, I've found that often, the root cause isn't a single component failure but a combination of factors, including operational procedures, maintenance practices, and even environmental conditions.

The Importance of Documentation

Thorough documentation is a cornerstone of effective industrial generator set failure analysis. Every inspection, maintenance activity, diagnostic test, and repair should be meticulously recorded. This creates a historical log that is invaluable for:

- Tracking recurring issues.

- Identifying patterns in failures.

- Evaluating the effectiveness of maintenance strategies.

- Providing data for future purchasing decisions.

- Ensuring compliance with warranty requirements.

Without proper records, it's like trying to solve a mystery without any clues. The data you collect today can prevent a costly failure tomorrow.

In conclusion, industrial generator set failure analysis is not a one-time event but an ongoing process. By understanding the common causes of failure, employing systematic diagnostic techniques, implementing robust preventative maintenance, and focusing on root cause identification, organizations can significantly enhance the reliability and longevity of their critical power generation assets. Investing in this proactive approach is an investment in business continuity and operational resilience.

For more detailed information, please visit our official website:industrial generator set failure analysis

About the author: The author, Alex Chen, is a seasoned field service engineer with over 15 years of experience in industrial power systems. He specializes in the maintenance, troubleshooting, and reliability of generator sets across various critical sectors. Alex is passionate about sharing practical insights to help businesses ensure uninterrupted power supply and optimize their equipment performance.