Pro cost of industrial power downtime Solutions Manufacturer

The Hidden Drain: Understanding the True Cost of Industrial Power Downtime

In the fast-paced world of modern industry, every second counts. A brief flicker of the lights or a momentary power sag might seem insignificant, but in a manufacturing plant, data center, or medical facility, it can trigger a catastrophic chain reaction of financial losses. This is the reality of the cost of industrial power downtime. It's not merely the inconvenience of restarting machinery; it's a deep and multifaceted expense that can cripple productivity, erode profits, and damage a company's reputation. As a premier manufacturer of power reliability solutions, we specialize in helping businesses quantify, understand, and ultimately eliminate this critical vulnerability.

The cost of a power outage extends far beyond the immediate halt in production. It can be broken down into several key areas. First, there are the tangible, immediate costs. This includes lost revenue from products that were not manufactured and shipped, the wages paid to an idle workforce, and the cost of raw materials that may be spoiled or ruined during the unplanned shutdown. For example, in industries like plastics, chemicals, or food processing, a sudden stop can cause materials within the machinery to solidify or spoil, requiring hours of costly and labor-intensive cleaning before production can resume.

Beyond these direct costs lie the intangible, long-term consequences, which are often more damaging. Reputational harm is a significant factor. Failing to meet delivery deadlines can lead to lost contracts and dissatisfied customers who may turn to more reliable competitors. In a tightly integrated supply chain, a single facility's downtime can cause a ripple effect, impacting partners and further straining business relationships. Furthermore, frequent restarts and hard shutdowns place immense stress on sensitive industrial equipment, leading to premature wear and tear, increased maintenance expenses, and a shortened operational lifespan for valuable assets. Analyzing the full spectrum of the cost of industrial power downtime is the first step toward building a resilient and profitable operation.

Our Core Solutions: A Comprehensive Approach to Power Reliability

Understanding the problem is only half the battle. As a specialist manufacturer, we have dedicated our expertise to engineering a comprehensive suite of solutions designed to provide seamless, reliable power under any circumstances. We don't offer one-size-fits-all products; we build integrated power protection ecosystems that are meticulously tailored to the unique demands of your facility. Our approach ensures that your critical operations are shielded from sags, surges, and complete outages, effectively neutralizing the threat of downtime.

Our solutions portfolio is built on a foundation of robust, industrial-grade hardware and intelligent software:

- Industrial Uninterruptible Power Supplies (UPS): The first line of defense. Our double-conversion online UPS systems provide the highest level of protection by completely isolating your equipment from raw utility power. They deliver a pure, stable sine wave of electricity, instantly switching to battery backup with zero transfer time in the event of a disturbance. This is critical for sensitive electronics, automated control systems, and IT infrastructure that cannot tolerate even a millisecond of power loss.

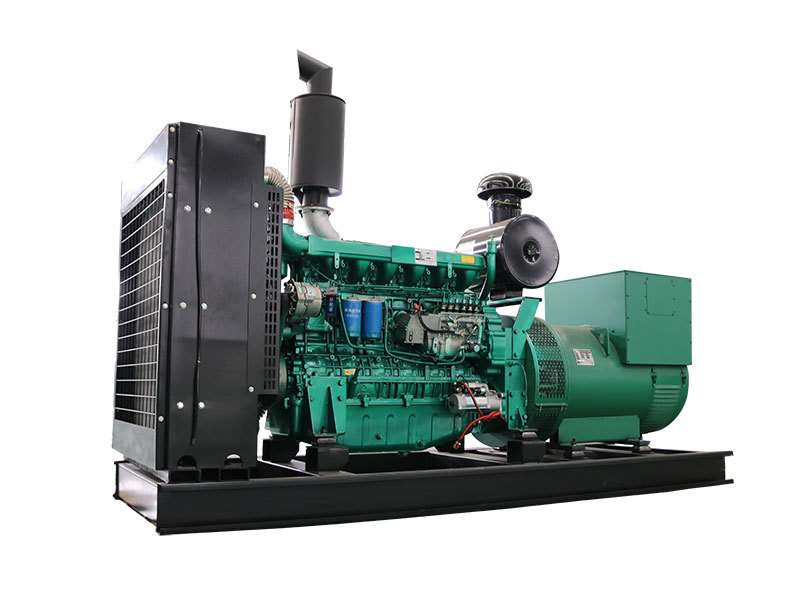

- Backup Power Generators: For extended outages that go beyond the capacity of a UPS battery, our industrial generators are the ultimate safeguard. Seamlessly integrated with an Automatic Transfer Switch (ATS), these generators automatically start and take over the electrical load, ensuring that your entire facility can continue to operate for hours or even days without interruption.

- Power Distribution and Management: Intelligent power management is key to reliability. Our Power Distribution Units (PDUs) allow for granular control and monitoring of power to individual racks or machines. The Automatic Transfer Switch (ATS) is the brain of the backup system, instantly and safely switching between utility and generator power.

- Advanced Monitoring Software: Knowledge is power. Our management software provides real-time visibility into your power ecosystem. You can monitor system status, receive proactive alerts about potential issues, analyze power quality trends, and manage your systems remotely, allowing you to prevent problems before they lead to downtime.

By integrating these components, we create a layered defense strategy. The UPS handles momentary flickers and conditions the power, while the generator stands ready for prolonged blackouts. This synergy provides a complete shield, ensuring that your operations remain productive and profitable, no matter what happens on the grid.

Key Advantages of Partnering with a Specialist Manufacturer

Choosing a power protection partner is a critical decision. While many vendors can sell you a piece of equipment, a true specialist manufacturer offers an end-to-end partnership that delivers superior value, reliability, and peace of mind. Our core advantage lies in our deep-seated engineering expertise and our direct control over the entire product lifecycle, from design and manufacturing to implementation and support.

When you partner with us, you gain several distinct benefits:

- Holistic System Design: We don't just sell boxes; we provide solutions. Our process begins with a thorough assessment of your operational risks and power requirements. Our engineers work with you to design a fully integrated system that is perfectly sized and configured for your specific application. This holistic approach ensures there are no weak links in your power protection chain.

- Uncompromising Component Quality: As the manufacturer, we have complete control over the quality of our products. We use only high-grade, durable components designed to withstand the harsh conditions of industrial environments, including temperature extremes, dust, and vibration. This commitment to quality translates into higher reliability and a longer service life for your investment.

- Scalability and Future-Proofing: Your business is not static, and your power protection system shouldn't be either. We design our solutions with scalability in mind. Our modular UPS systems and flexible generator configurations allow you to easily expand your power capacity as your operational needs grow, ensuring your initial investment remains valuable for years to come.

- Direct Engineering Expertise: When you have a technical question or need support, you are speaking directly with the experts who designed and built the system. This direct line of communication eliminates confusion and ensures you receive fast, accurate, and effective support, from initial consultation to long-term maintenance. This expertise is crucial when evaluating the complex factors that contribute to the cost of industrial power downtime.

Diverse Applications: Protecting Critical Operations Across Industries

The need for uninterrupted power is universal, but the specific challenges vary significantly from one industry to another. Our extensive experience as a manufacturer has allowed us to develop specialized solutions that address the unique pain points of diverse sectors. We understand that for a hospital, downtime is a matter of life and death, while for a semiconductor fab, it's a matter of multi-million-dollar losses. Our systems are engineered to meet these exacting standards.

Our solutions are deployed in a wide range of critical environments:

- Advanced Manufacturing & Automation: In modern factories, robotic arms, CNC machines, and automated assembly lines rely on precise, continuous power. A brief outage can cause production lines to halt, leading to costly material waste, extensive reset procedures, and potential damage to robotic equipment. Our UPS and generator solutions ensure these automated systems run flawlessly 24/7.

- Data Centers and IT: Data is the lifeblood of the digital economy. For data centers, colocation facilities, and enterprise server rooms, 100% uptime is non-negotiable. Our power solutions guarantee the continuous operation of servers, storage arrays, and networking equipment, preventing data loss, service interruptions, and security breaches.

- Healthcare and Pharmaceuticals: In hospitals, our systems protect life-support equipment in operating rooms and ICUs, as well as critical imaging machines like MRIs and CT scanners. In pharmaceutical labs, they safeguard sensitive research, climate-controlled environments, and valuable refrigerated biological samples from spoilage.

- Logistics and Warehousing: Automated sorting systems, inventory management servers, and communication networks are the heart of modern logistics hubs. Power downtime can bring the entire supply chain to a standstill. We provide the power backbone to keep goods moving efficiently.

By providing reliable power to these and many other industries, we play a vital role in protecting critical infrastructure, ensuring public safety, and driving economic productivity. Our ability to customize solutions for each specific application is what sets us apart.

Our Commitment to Quality: Manufacturing and Certification

At the core of our promise is an unwavering commitment to quality. As a direct manufacturer, we believe that true reliability is not a feature but a fundamental principle that must be embedded in every stage of the production process. We don't outsource our core manufacturing, because we believe that direct oversight is the only way to guarantee the superior performance and longevity that our customers expect and deserve. This hands-on approach is our definitive answer to mitigating the high cost of industrial power downtime.

Our quality assurance is built on three pillars:

- State-of-the-Art Manufacturing Facilities: Our production lines are equipped with advanced machinery and operated by a highly skilled technical team. We follow lean manufacturing principles to ensure efficiency, consistency, and precision in every unit we produce. From circuit board assembly to the final chassis construction, every step is meticulously controlled.

- Rigorous Multi-Stage Testing: Quality is verified, not assumed. Every component is tested before assembly, and every completed system undergoes a series of rigorous performance and stress tests. This includes full-load testing, battery rundown simulations, and environmental chamber tests to ensure our products perform flawlessly in real-world conditions. This exhaustive process ensures that the unit arriving at your facility is ready for its critical mission.

- Adherence to International Standards: Trust is earned through verification. Our facilities and products comply with major international quality and safety certifications. This includes ISO 9001 for our quality management systems, as well as product-specific certifications like CE (for the European market) and UL (for safety in North America). These certifications are a testament to our global standards of excellence.

By managing the entire manufacturing process, we ensure a level of quality, accountability, and reliability that resellers or assemblers simply cannot match. When you choose our solutions, you are choosing a product built with integrity from the ground up.

Flexible Purchasing and Partnership Models for All Customers

We believe that world-class power protection should be accessible to everyone, from large multinational corporations to small, specialized businesses and even individual operators with critical needs. Our business model is designed for flexibility, offering tailored purchasing options and comprehensive support for both wholesale and retail customers. We are committed to being a long-term partner in your success, regardless of the scale of your operation.

We proudly support a diverse range of clients:

- For Businesses (Wholesale & Project-Based Orders): We excel at handling large-scale industrial projects. Our corporate clients benefit from dedicated project managers, custom-engineered solutions, and attractive volume pricing. We understand that every project is unique, which is why we offer flexible Minimum Order Quantities (MOQs) and extensive customization options, from specific power ratings to unique form factors and software integration.

- For Individuals & Small Businesses (Retail & Single Orders): We warmly welcome personal purchases. Whether you are a researcher with a small lab, an IT professional with a critical home server, or a workshop owner with sensitive equipment, we have standardized, high-quality solutions ready for you. Our expert team is available to provide the same level of consultation to help you select the perfect unit for your needs, ensuring you receive industrial-grade protection at an accessible scale.

Our partnership extends far beyond the initial sale. We offer a comprehensive after-sales service and support package that includes:

- Installation Assistance: Guidance and support to ensure your system is commissioned correctly and safely.

- Preventive Maintenance Plans: Customizable service plans to proactively maintain your equipment, maximizing its lifespan and reliability.

- Robust Warranty and Technical Support: A strong manufacturer's warranty backed by a responsive and knowledgeable technical support team ready to assist you.

Our goal is to build lasting relationships by providing exceptional products and unwavering support. We are here to help you protect your assets, secure your operations, and achieve your business objectives with confidence.

For more detailed information, please visit our official website:industrial power outage costs

About the author: David Chen is a Senior Power Systems Engineer with over 15 years of experience in designing and implementing critical power infrastructure. Specializing in industrial power reliability and downtime cost analysis, David helps businesses across manufacturing, healthcare, and IT sectors build resilient operations. He is passionate about engineering robust solutions that safeguard critical assets and ensure operational continuity in an increasingly power-dependent world. ---