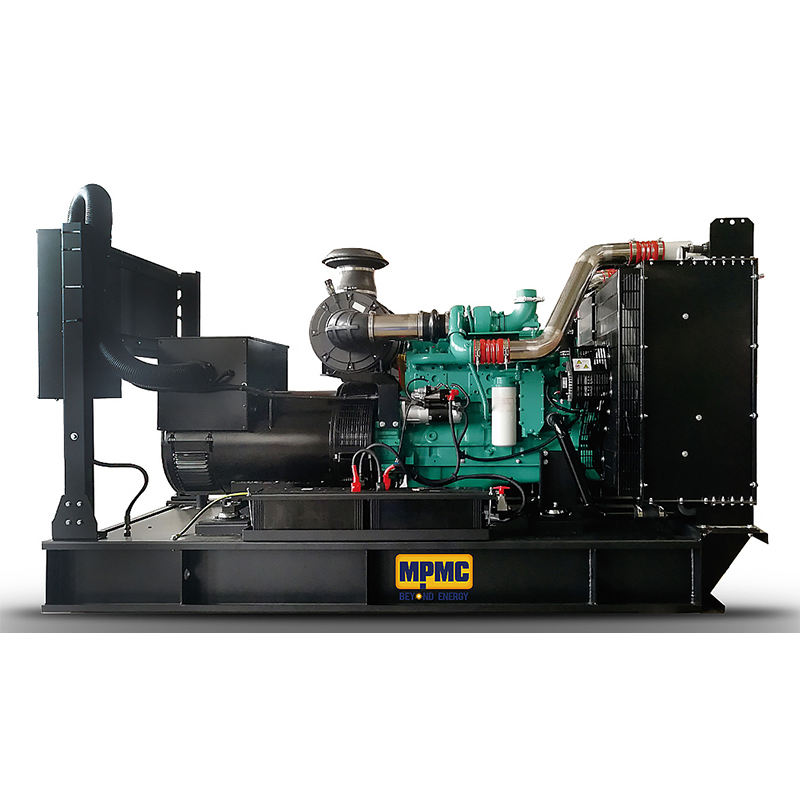

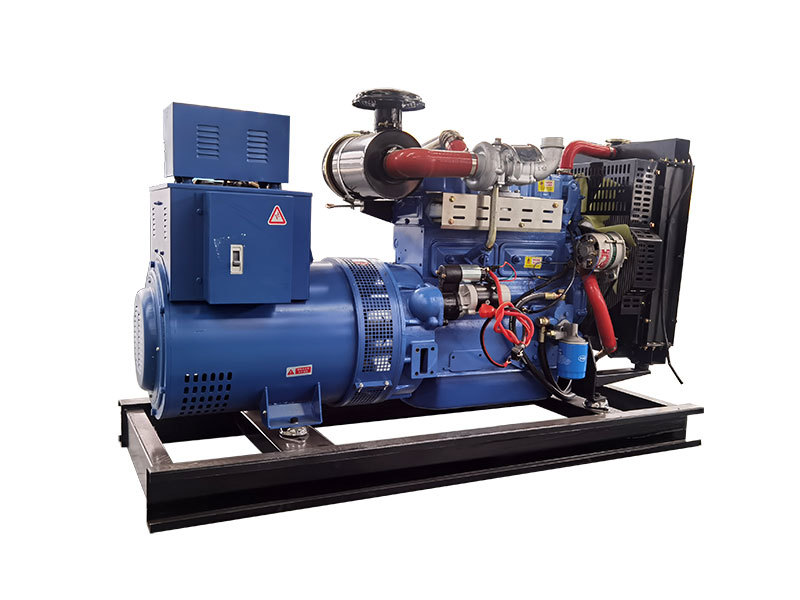

Powering Progress: Unveiling the World of a Leading Generator Set Manufacturer

Have you ever stopped to consider what keeps hospitals running during a blackout, or ensures data centers never lose critical information? Frankly speaking, the unsung heroes behind this continuous power supply are often the dedicated professionals at a leading Generator set manufacturer. These companies are the backbone of modern infrastructure, providing the essential power generation equipment that keeps our world moving, even when the grid fails.

To be honest, the complexity and precision involved in designing, fabricating, and testing these powerful machines are truly remarkable. It's not just about assembling an engine and an alternator; it's about engineering integrated systems that deliver reliable, efficient, and often customized power solutions for a vast array of applications. From emergency standby power to prime power for remote operations, the demand for high-quality generator sets is constant and growing.

The Crucial Role of a Generator Set Manufacturer in Modern Infrastructure

A Generator set manufacturer isn't merely a supplier; they are a partner in ensuring operational continuity and energy independence for businesses and critical services worldwide. Their expertise spans across various domains, from understanding the nuances of different fuel types to integrating advanced control systems and ensuring compliance with stringent environmental regulations. In my experience, the best manufacturers don't just sell products; they offer comprehensive power solutions tailored to specific needs.

Interestingly enough, the scope of a generator set manufacturer's work is incredibly broad. They cater to diverse sectors, including:

- Healthcare: Ensuring life-saving equipment remains operational during power outages.

- Data Centers: Providing uninterrupted power to protect invaluable digital assets.

- Manufacturing: Maintaining production lines to avoid costly downtime.

- Construction: Supplying portable power for remote job sites.

- Telecommunications: Keeping communication networks online.

- Utilities: Offering backup power for critical infrastructure.

This wide array of applications necessitates an equally diverse product portfolio. A reputable Generator set manufacturer will offer a range of options, including diesel, natural gas, propane, and even hybrid generator sets, each with its own advantages depending on the application, fuel availability, and environmental considerations. They are at the forefront of delivering robust industrial power generation solutions that can withstand the most demanding environments.

Understanding Different Generator Set Types and Their Applications

When we talk about generator sets, it's important to recognize that one size certainly does not fit all. The type of generator set required depends heavily on its intended use, power requirements, and operational environment.

- Diesel Generator Sets: These are arguably the most common and widely used due to their high power output, fuel efficiency, and durability. They are ideal for prime power, standby power, and continuous operation in industrial and commercial settings. Many experts agree that for sheer ruggedness and reliability, diesel remains a top choice.

- Natural Gas Generator Sets: Offering cleaner emissions and often lower fuel costs (depending on local gas prices), natural gas generators are gaining popularity, especially in urban areas where emissions regulations are stricter. They are excellent for continuous and standby applications where a natural gas line is readily available.

- Bi-Fuel and Hybrid Systems: Some manufacturers are innovating with bi-fuel systems (e.g., diesel and natural gas) or hybrid solutions that combine generators with battery storage or renewable energy sources like solar. These offer enhanced efficiency, reduced fuel consumption, and lower environmental impact.

- Portable and Mobile Generators: Designed for flexibility, these units are crucial for construction sites, outdoor events, emergency response, and any situation requiring temporary power. They are typically smaller and mounted on trailers for easy transportation.

The selection process is critical, and a knowledgeable Generator set manufacturer will guide clients through the options, ensuring the chosen solution perfectly matches the specific power needs and operational context.

What to Look for in a Top-Tier Generator Set Manufacturer

Choosing the right Generator set manufacturer is paramount to ensuring long-term reliability and performance. It's an investment, and like any significant investment, due diligence is key. I've found that several core attributes distinguish a truly top-tier manufacturer from the rest.

First and foremost, look for a manufacturer with a proven track record. Experience in the industry often translates to a deeper understanding of customer needs, robust engineering practices, and a refined manufacturing process. A company that has been around for decades has likely weathered various economic cycles and technological shifts, continually adapting and improving its offerings.

Here are some critical factors to consider:

- Engineering Excellence and Innovation: A leading manufacturer invests heavily in R&D, constantly seeking to improve efficiency, reduce emissions, and integrate smart technologies. They should be able to offer cutting-edge solutions, including advanced control systems and remote monitoring capabilities.

- Quality Control and Certifications: Rigorous quality control at every stage of production is non-negotiable. Look for manufacturers with ISO certifications (e.g., ISO 9001 for quality management) and adherence to international standards like CE, UL, or CSA, which signify a commitment to safety and performance.

- Customization Capabilities: Not all power needs are standard. A superior Generator set manufacturer will offer significant custom generator set fabrication capabilities, allowing them to design and build units that precisely meet unique specifications, whether it's for specific dimensions, noise reduction requirements, or specialized control features.

- After-Sales Support and Service: The relationship doesn't end with the sale. A strong after-sales network, including readily available spare parts, technical support, and maintenance services, is crucial for the longevity and reliable operation of your generator set. This includes preventative maintenance programs and rapid response for emergencies.

- Reputation and Customer Testimonials: What do existing clients say? Look for positive reviews, case studies, and testimonials that highlight customer satisfaction, product reliability, and responsive service. A good reputation is earned through consistent performance and dedication.

- Global Reach and Local Presence: For international operations or businesses with multiple sites, a manufacturer with a global footprint can offer consistent quality and support wherever your operations are located. However, local service and support teams are equally vital for quick response times.

The Manufacturing Process: From Concept to Power

The journey of a generator set from concept to a fully operational unit is a complex one, involving multiple stages of design, fabrication, assembly, and rigorous testing. A top-tier Generator set manufacturer orchestrates this intricate process with precision and expertise.

It all begins with design and engineering. This phase involves detailed calculations, CAD modeling, and simulations to ensure the generator set meets specific power requirements, environmental conditions, and regulatory standards. Components like the engine, alternator, control panel, cooling system, and base frame are carefully selected and optimized for compatibility and performance. This is where the foundation for a truly reliable standby power system is laid.

Following design, the manufacturing process moves to fabrication. This includes cutting and welding the robust steel base frames, fabricating enclosures for noise attenuation and weather protection, and preparing mounting points for all components. Precision is paramount here, as any misalignment can lead to vibrations and premature wear.

Assembly and Quality Assurance: The Heart of Production

The assembly line is where all the individual components come together. The engine, often sourced from renowned global manufacturers, is integrated with the alternator, which converts mechanical energy into electrical power. The control panel, the "brain" of the generator, is then meticulously wired and programmed. This panel monitors various parameters, manages power output, and provides critical safety features.

Frankly speaking, one of the most critical stages is quality assurance and testing. Every generator set undergoes a series of stringent tests before it leaves the factory. These tests include:

- Load Bank Testing: The generator is run at various load levels (0%, 25%, 50%, 75%, 100%, and even overload) to verify its power output, voltage regulation, frequency stability, and fuel consumption under real-world conditions.

- Noise and Vibration Testing: Especially for units destined for sensitive environments, noise levels and vibration are carefully measured to ensure they meet specified limits.

- Safety Feature Checks: All safety shutdowns, alarms, and emergency stop functions are thoroughly tested to ensure operator and equipment protection.

- Environmental Testing: For specific applications, units might be tested under extreme temperature or humidity conditions.

This comprehensive testing regimen is what truly sets a reliable Generator set manufacturer apart. It provides assurance that the unit will perform as expected when it's most needed.

Ensuring Reliability: Standby Power and Beyond

The primary function of many generator sets, particularly in critical applications, is to provide reliable standby power systems. This means they must activate automatically and seamlessly when the main power grid fails, ensuring no disruption to essential operations. Achieving this level of reliability requires not only a well-built machine but also proper installation, regular maintenance, and a robust support infrastructure.

Many experts agree that the true cost of a generator set isn't just its purchase price; it's the total cost of ownership over its lifespan, which includes fuel, maintenance, and potential downtime. A reputable Generator set manufacturer understands this and designs units for ease of serviceability and long operational life. They also emphasize the importance of using genuine parts for replacements to maintain performance and warranty validity.

Consider a hospital, for instance. A power outage could be catastrophic without immediate backup power. The generator set must start within seconds, take on the full load, and continue running for as long as necessary. This isn't just about having a generator; it's about having a fully integrated, tested, and reliable standby power solution. The manufacturer plays a crucial role in advising on sizing, installation requirements, and ongoing service plans to ensure this critical functionality.

Beyond standby applications, generator sets are also vital for prime power in remote locations where grid power is unavailable or unreliable. Mining operations, remote villages, oil and gas exploration sites, and agricultural facilities often rely entirely on generator sets for their daily power needs. In these scenarios, fuel efficiency, durability, and ease of maintenance become even more critical factors. The manufacturer's ability to provide robust, long-lasting solutions for these challenging environments is a testament to their engineering prowess.

The Future of Generator Sets: Innovation and Sustainability

The power generation landscape is constantly evolving, driven by technological advancements, environmental concerns, and shifting energy policies. A forward-thinking Generator set manufacturer is not just reacting to these changes but actively shaping the future of power.

One significant trend is the push towards cleaner energy. This involves developing generator sets that run on alternative fuels like bio-diesel, hydrogen, or even synthetic fuels. Manufacturers are also focusing on improving combustion efficiency to reduce emissions and comply with increasingly stringent environmental regulations.

Another exciting area of innovation is the integration of smart technologies. Modern generator sets are equipped with advanced control systems that allow for remote monitoring, predictive maintenance, and seamless integration with building management systems. This connectivity enables operators to monitor performance, diagnose issues, and even control units from anywhere in the world, significantly enhancing reliability and reducing operational costs.

Furthermore, hybrid power solutions are becoming more prevalent. These systems combine generator sets with renewable energy sources (like solar or wind) and battery storage. The generator acts as a backup or supplements the renewables when demand is high or renewable generation is low, leading to reduced fuel consumption and a smaller carbon footprint. This holistic approach to power generation is something a leading Generator set manufacturer is actively pursuing.

Choosing Your Power Partner Wisely

In conclusion, the role of a Generator set manufacturer is far more significant than simply producing machinery. They are integral to ensuring the continuity of essential services, supporting industrial growth, and providing critical power solutions across the globe. From the initial design to after-sales support, their commitment to quality, innovation, and customer satisfaction directly impacts the reliability of our power infrastructure.

When you're considering an investment in power generation, remember that selecting the right manufacturer is a decision that will pay dividends in peace of mind, operational efficiency, and long-term cost savings. Look for a partner who understands your unique needs, offers proven technology, and stands behind their products with comprehensive support.

What aspects of generator set technology do you find most fascinating, and how do you envision the future of industrial power generation?

For more detailed information, please visit our official website:Generator set manufacturer

About the author: Markus Thorne is a seasoned expert in industrial power solutions with over two decades of experience in the energy sector. Specializing in generator set technology and power systems engineering, Markus has advised countless businesses on optimizing their energy infrastructure. His insights, drawn from extensive field work and industry analysis, focus on practical, reliable, and sustainable power generation strategies.