Powering Progress: What Defines a Leading Diesel Generator Manufacturer?

To be honest, in today's interconnected world, the demand for reliable, uninterrupted power has never been more critical. From bustling data centers and sprawling industrial complexes to remote construction sites and essential healthcare facilities, a consistent power supply is the backbone of operations. This is precisely where a top-tier Diesel generator manufacturer steps in, providing the indispensable backup and prime power solutions that keep our world running smoothly.

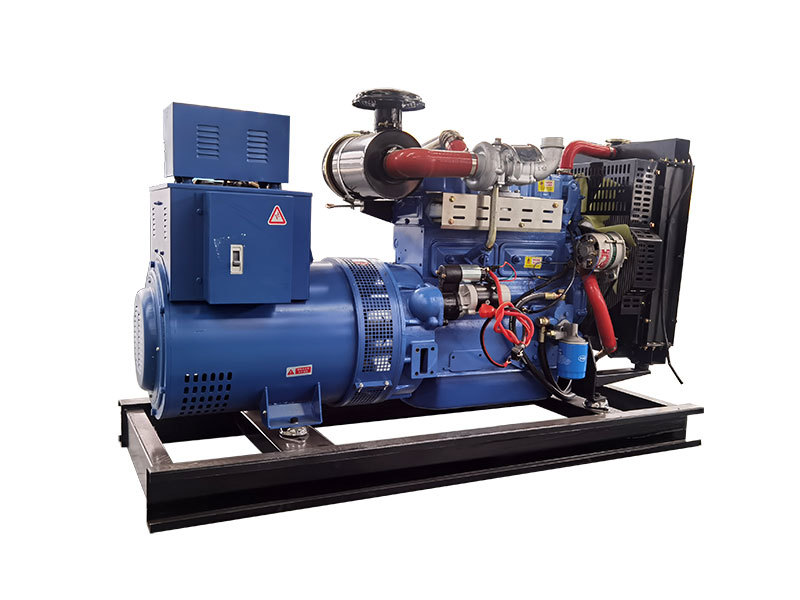

Have you ever wondered about the intricate process behind creating these robust machines? It's far more complex than simply assembling an engine and an alternator. It involves precision engineering, rigorous testing, and an unwavering commitment to quality. In my experience, the difference between a good generator and a truly exceptional one often lies in the philosophy and capabilities of its manufacturer.

This article will delve deep into the world of diesel generators, exploring what sets leading manufacturers apart, the critical factors to consider when making a choice, and the innovative strides being made in this vital industry. We'll uncover the secrets behind reliable generator production and why partnering with the right company is a strategic investment for any enterprise.

The Crucial Role of a Diesel Generator Manufacturer in Modern Infrastructure

Frankly speaking, without reliable power, modern infrastructure grinds to a halt. Hospitals can't perform life-saving surgeries, communication networks fail, and manufacturing lines cease production. This stark reality underscores the paramount importance of a dedicated Diesel generator manufacturer. They are not just selling equipment; they are providing peace of mind, ensuring continuity, and safeguarding critical operations against unforeseen power outages.

A reputable manufacturer understands that their products are often the last line of defense against operational disruption. They cater to a diverse range of applications, each with its unique demands:

- Industrial Sector: Powering heavy machinery, factories, and large-scale production facilities where downtime can cost millions.

- Commercial Buildings: Ensuring lights stay on, elevators run, and essential services remain active in offices, retail spaces, and hotels.

- Data Centers: Providing uninterrupted power to servers and cooling systems, preventing data loss and service interruptions that could have global repercussions.

- Healthcare Facilities: Maintaining critical life support systems, operating rooms, and diagnostic equipment during emergencies.

- Construction and Mining: Supplying prime power to remote sites where grid access is unavailable or unreliable.

Beyond Just Power: The Core Offerings

It's worth noting that a leading Diesel generator manufacturer offers more than just a generator set. They provide comprehensive power solutions. This often includes:

- Consultation and Design: Helping clients assess their power needs and design a system that perfectly fits their application.

- Customization: Offering bespoke solutions for unique environmental conditions or specific power requirements, including specialized enclosures, fuel tanks, and control systems.

- Installation Support: Guiding or assisting with the proper setup and integration of the generator into existing infrastructure.

- After-Sales Service: Providing maintenance, parts, and technical support to ensure the longevity and optimal performance of the unit.

Why Reliability is Non-Negotiable

Many experts agree that the true measure of a generator is its reliability when it matters most. This isn't just about the engine starting; it's about consistent performance under load, fuel efficiency, and minimal maintenance requirements. A manufacturer committed to reliable generator production invests heavily in research and development, using advanced materials and cutting-edge technology to build units that withstand the test of time and extreme conditions. They understand that every component, from the alternator to the control panel, must be of the highest quality to ensure seamless operation.

Key Considerations When Choosing a Diesel Generator Manufacturer

Choosing the right Diesel generator manufacturer is a decision that impacts long-term operational efficiency and financial outlay. It’s not a purchase to be taken lightly. I've found that focusing on a few critical areas can significantly narrow down the best options and ensure you make an informed choice.

The Technology Behind the Power

First and foremost, look at the technology and components used. A top manufacturer will partner with renowned engine brands (like Cummins, Perkins, Volvo Penta, MTU) and alternator suppliers (like Stamford, Leroy-Somer, Mecc Alte). The integration of these high-quality components is crucial. Furthermore, consider the control systems. Modern generators feature sophisticated digital controllers that allow for remote monitoring, automatic transfer switch integration, and advanced diagnostics. These features enhance reliability and ease of use, which, to be honest, can save a lot of headaches down the line.

Another aspect is the ability to provide custom diesel power solutions. Every client's needs are unique. A manufacturer that can tailor generator sets to specific requirements—whether it's a particular voltage, sound attenuation level, extreme temperature operation, or specialized fuel tank capacity—demonstrates flexibility and a deep understanding of diverse applications. This bespoke approach ensures the solution is perfectly aligned with your operational demands, rather than a one-size-fits-all compromise.

Service and Support: The Unsung Heroes

Interestingly enough, the quality of after-sales service can be as important as the generator itself. What happens if a part fails? How quickly can technical support be dispatched? A leading Diesel generator manufacturer will have a robust global or regional service network, readily available spare parts, and highly trained technicians. This ensures minimal downtime and extends the lifespan of your investment. Look for manufacturers who offer comprehensive warranty programs and preventative maintenance contracts. In my experience, a strong service commitment speaks volumes about a manufacturer's confidence in their product.

Finally, certifications and adherence to international standards (like ISO 9001 for quality management, ISO 14001 for environmental management, and various emission standards) are non-negotiable. These certifications are not just badges; they represent a commitment to quality, safety, and environmental responsibility throughout the manufacturing process. They provide an assurance that the product you receive meets stringent global benchmarks.

The Manufacturing Process: From Raw Materials to Robust Powerhouses

The journey of a diesel generator from raw materials to a ready-to-deploy powerhouse is a testament to modern engineering and meticulous quality control. A leading Diesel generator manufacturer orchestrates a complex symphony of design, sourcing, assembly, and rigorous testing to ensure each unit performs flawlessly. Frankly speaking, this is where true expertise shines through.

Precision Engineering and Innovation

It all begins with design and engineering. Utilizing advanced CAD/CAM software, engineers meticulously design every component, ensuring optimal performance, durability, and ease of maintenance. This phase often involves extensive simulations to predict how the generator will perform under various loads and environmental conditions. The selection of materials is critical – from high-grade steel for the chassis to robust copper for the alternator windings. A manufacturer committed to reliable generator production will prioritize quality materials that can withstand the demands of continuous operation and harsh environments.

Component sourcing is another vital step. Reputable manufacturers establish long-term relationships with trusted suppliers for engines, alternators, control panels, radiators, and other critical parts. This ensures consistency in quality and performance across their product lines. Interestingly enough, many manufacturers also invest in vertical integration, producing certain key components in-house to maintain tighter control over quality and innovation.

Rigorous Testing for Unwavering Performance

Once components are sourced, the assembly process begins. This is not merely putting parts together; it's a precise operation, often involving automated systems alongside skilled technicians. Each stage of assembly is typically followed by quality checks. But the real test comes after the unit is fully assembled.

Every single generator undergoes a series of stringent tests before it leaves the factory floor. These tests include:

- Load Bank Testing: Running the generator at various loads (0%, 25%, 50%, 75%, 100%, and even overload) for extended periods to verify its power output, voltage regulation, frequency stability, and temperature management.

- Sound Level Testing: Measuring noise output, especially for units designed for residential or urban environments.

- Vibration Analysis: Ensuring smooth operation and identifying any potential issues that could lead to premature wear.

- Fuel Consumption Testing: Verifying efficiency and operational cost estimates.

- Safety Feature Checks: Testing emergency shutdowns, alarms, and protective relays.

This rigorous testing regimen is what truly defines a commitment to reliable generator production. It ensures that when the generator is deployed, it performs exactly as expected, even in critical situations. Many experts agree that this comprehensive testing is non-negotiable for any serious buyer.

Innovation and Sustainability in Diesel Generator Manufacturing

The landscape of power generation is constantly evolving, and a forward-thinking Diesel generator manufacturer is at the forefront of this change. While diesel generators are known for their robustness and efficiency, there's a growing emphasis on innovation, particularly concerning environmental impact and smart technology. It's worth noting that manufacturers are not resting on their laurels; they are actively developing solutions for a greener, more connected future.

Greener Power: Advancements in Emission Control

One of the most significant areas of innovation is emissions reduction. Modern diesel generators are far cleaner than their predecessors, thanks to advancements in engine technology and exhaust after-treatment systems. Manufacturers are incorporating:

- Tier-compliant Engines: Adhering to strict emission standards (e.g., EPA Tier 4 Final, EU Stage V) through technologies like Selective Catalytic Reduction (SCR) and Diesel Particulate Filters (DPF).

- Alternative Fuels: Exploring the use of biodiesel blends, HVO (Hydrotreated Vegetable Oil), and even gas-diesel hybrid solutions to reduce carbon footprint.

- Optimized Combustion: Improving engine design to achieve more complete fuel combustion, leading to higher efficiency and lower emissions.

These advancements demonstrate a commitment to sustainability, allowing businesses to meet environmental regulations while still benefiting from the reliability of diesel power. In my experience, clients are increasingly prioritizing these eco-friendly features.

The Rise of Smart Generators

Another fascinating trend is the integration of smart technology. Modern generators are no longer just standalone machines; they are becoming intelligent, connected devices. A leading Diesel generator manufacturer now offers units equipped with:

- Remote Monitoring and Control: Allowing operators to monitor performance, fuel levels, and maintenance needs from anywhere in the world via a smartphone or computer.

- Predictive Maintenance: Using data analytics to anticipate potential failures before they occur, enabling proactive servicing and preventing costly downtime.

- Grid Synchronization: Enabling generators to seamlessly integrate with the main power grid, allowing for peak shaving, load management, and even selling excess power back to the grid.

- Hybrid Solutions: Combining diesel generators with renewable energy sources like solar panels or battery storage systems for enhanced efficiency, reduced fuel consumption, and lower emissions. These systems offer the best of both worlds: the reliability of diesel with the sustainability of renewables.

These innovations are transforming how businesses manage their power infrastructure, offering greater control, efficiency, and resilience. Many experts agree that smart generators represent the future of reliable backup power.

The Global Reach and Impact of Industrial Diesel Generator Suppliers

The market for power generation equipment is inherently global, driven by diverse energy needs, infrastructure development, and the ever-present threat of power disruptions. Industrial diesel generator suppliers play a pivotal role in this intricate global ecosystem, ensuring that critical sectors worldwide have access to robust and dependable power solutions. Frankly speaking, their impact extends far beyond just selling units; they are enablers of progress and stability on an international scale.

Navigating International Standards and Demands

Operating globally means a manufacturer must be adept at navigating a complex web of international standards, regulations, and logistical challenges. Different regions have varying emission standards, electrical codes, and environmental requirements. A truly global Diesel generator manufacturer will have the expertise and product range to meet these diverse demands, ensuring compliance and optimal performance wherever their generators are deployed. This often involves maintaining regional sales and service offices, as well as a robust network of distributors and partners.

The logistics of transporting large, heavy generator sets across continents also requires specialized knowledge and infrastructure. From secure packaging and efficient shipping routes to customs clearance and local delivery, the supply chain must be meticulously managed to ensure timely and safe arrival. In my experience, the ability to deliver on time, every time, is a hallmark of a truly reliable supplier.

The impact of these suppliers is particularly evident in developing nations or regions with unstable grids. Here, diesel generators often serve as the primary power source for essential services, driving economic growth and improving living standards. They power remote villages, support agricultural operations, and enable the expansion of telecommunications networks. For instance, in areas prone to natural disasters, the rapid deployment of generators by industrial diesel generator suppliers can mean the difference between widespread chaos and organized recovery efforts.

Furthermore, the global market for industrial diesel generator suppliers is highly competitive, fostering continuous innovation and a drive for efficiency. This competition ultimately benefits the end-user, leading to more advanced, reliable, and cost-effective power solutions. The ability to offer custom diesel power solutions on a global scale further solidifies their position as indispensable partners for businesses and governments alike.

Partnering with the Right Diesel Generator Manufacturer: A Strategic Investment

Ultimately, choosing a Diesel generator manufacturer is not just a procurement decision; it's a strategic investment in the continuity, safety, and efficiency of your operations. The initial cost of a generator is only one part of the equation. The long-term value comes from its reliability, fuel efficiency, maintenance requirements, and the quality of support you receive over its lifespan. Many experts agree that cutting corners here can lead to far greater costs down the line in terms of downtime, repairs, and lost productivity.

When you partner with a manufacturer committed to reliable generator production, you're investing in peace of mind. You're ensuring that your critical systems will remain operational, your data will be secure, and your business can continue to function, even when the unexpected happens. This long-term perspective is crucial. A strong relationship with your supplier means access to expert advice, timely service, and potentially, future upgrades or expansions as your power needs evolve.

Have you ever considered the true cost of a power outage for your business? It's often far higher than the price of a quality backup power system. From lost revenue and damaged equipment to compromised safety and reputational harm, the consequences can be severe. This is why the decision to invest in a generator from a reputable Diesel generator manufacturer is an act of foresight and responsible business management.

In conclusion, whether you're looking for prime power for a remote mining operation, standby power for a hospital, or a bespoke solution for a data center, the choice of your Diesel generator manufacturer will dictate the success and resilience of your power infrastructure. Look for a partner who prioritizes quality, embraces innovation, offers comprehensive support, and has a proven track record of delivering reliable power solutions. It's an investment that truly pays dividends when the lights go out.

For more detailed information, please visit our official website:Diesel generator manufacturer

About the author: Markus Thorne is a seasoned expert in industrial power solutions with over 20 years of experience in the energy sector. Specializing in generator technology and critical power infrastructure, Markus has advised numerous businesses on optimizing their energy resilience. His insights, drawn from extensive field work and industry analysis, focus on practical, reliable, and sustainable power strategies.