The term "export quality generator sets" signifies a commitment to manufacturing and delivering power generation equipment that meets stringent international standards and regulations. It's more than just assembling components; it's about engineering robust, reliable, and efficient power solutions designed to perform flawlessly in diverse environments across the globe. These generator sets must not only withstand the rigors of long-distance transportation but also operate effectively under varying climate conditions, fuel qualities, and operational demands. Selecting an export quality generator set provides businesses and organizations with the assurance of a consistent and dependable power source, minimizing downtime and maximizing productivity, regardless of location. It’s a crucial investment, particularly for industries that heavily rely on uninterrupted power, such as manufacturing, telecommunications, healthcare, and construction, especially in regions where the power grid is unreliable or non-existent. The specifications, testing, and documentation associated with these generator sets are far more detailed compared to those intended for domestic use. Are you considering what specific certifications are essential for your target market?

Understanding Key Components and Specifications

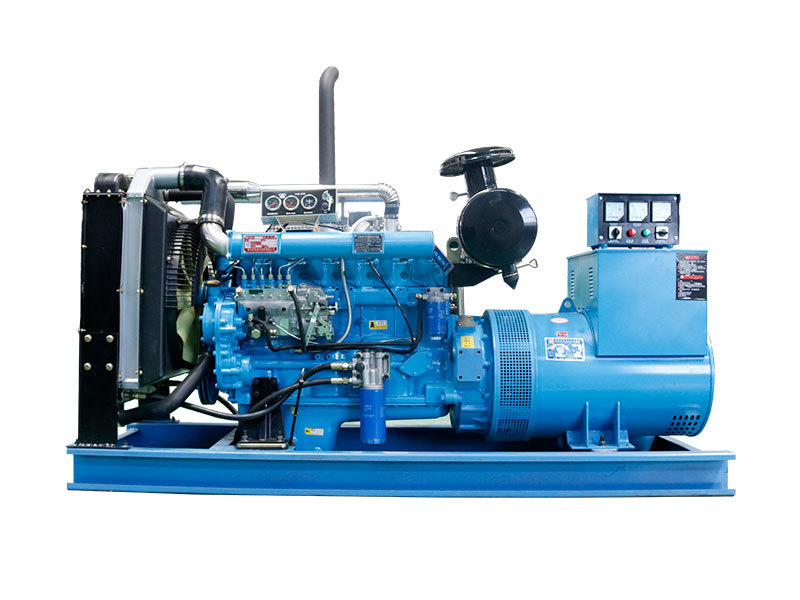

Delving into the specifics of export quality generator sets reveals a complex interplay of engineering and material science. The engine, often the heart of the generator set, must be capable of handling various fuel types, including diesel, natural gas, or biogas, depending on availability and regulations in the target export market. Key considerations include fuel efficiency, emissions compliance, and durability. The alternator, responsible for converting mechanical energy into electrical energy, must be precisely matched to the engine's capabilities and designed to deliver stable voltage and frequency, even under fluctuating loads. Control panels, often incorporating advanced digital controllers, provide real-time monitoring, protection features, and remote control capabilities. All these components need to adhere to globally recognized standards like ISO 8528, which specifies performance criteria for reciprocating internal combustion engine driven alternating current generator sets. The choice of materials is also critical. For example, the use of marine-grade paint and corrosion-resistant components are vital for generator sets destined for coastal regions where exposure to salt air is inevitable. The packaging and protection during transportation are equally important, often involving specialized crating and moisture-resistant barriers.

Engine Considerations for Export Markets

The selection of the engine for an export quality generator set involves careful consideration of several factors specific to the intended market. Fuel availability and quality can vary significantly from one region to another. An engine designed to run efficiently on high-quality diesel may suffer performance issues or even damage if operated on lower-grade fuel. Therefore, manufacturers often offer engine options optimized for different fuel types and qualities. Emission regulations are another critical aspect. Countries like the United States and the European Union have stringent emission standards that engines must meet. However, other regions may have less stringent requirements, or none at all. Selecting an engine that complies with the regulations of the target market is essential for legal and environmental reasons. Furthermore, the availability of spare parts and qualified service technicians in the target market should also be considered. Opting for a widely used engine model with a well-established service network can minimize downtime and ensure long-term reliability. Ultimately, the engine selection is a crucial decision that directly impacts the performance, reliability, and longevity of the generator set.

Alternator Performance and Reliability

The alternator is the component of the generator set responsible for converting the engine's mechanical power into usable electrical power. Its performance is critical to the overall efficiency and reliability of the generator set. An export quality alternator must be designed to withstand the rigors of continuous operation, often under demanding environmental conditions. Key performance parameters include voltage regulation, frequency stability, and harmonic distortion. Voltage regulation refers to the alternator's ability to maintain a stable output voltage, even under varying loads. Poor voltage regulation can damage sensitive electronic equipment. Frequency stability refers to the alternator's ability to maintain a constant output frequency, typically 50 Hz or 60 Hz, depending on the region. Fluctuations in frequency can also damage equipment and disrupt operations. Harmonic distortion refers to the presence of unwanted electrical frequencies in the output waveform. High harmonic distortion can lead to overheating of electrical equipment and interference with communications systems. To ensure optimal performance and reliability, export quality alternators typically incorporate features such as automatic voltage regulators (AVRs), high-efficiency windings, and robust insulation systems.

Compliance and Certification for Global Markets

Navigating the landscape of international standards and certifications is crucial when dealing with export quality generator sets. Compliance with standards like ISO 8528, as mentioned earlier, ensures that the generator set meets internationally recognized performance criteria. However, specific certifications may be required depending on the target market. For instance, CE marking is mandatory for generator sets sold in the European Union, indicating that the product meets EU health, safety, and environmental protection requirements. Similarly, UL certification is often required for products sold in North America, demonstrating compliance with safety standards established by Underwriters Laboratories. Other relevant certifications may include CSA (Canadian Standards Association), CCC (China Compulsory Certification), and various regional or national certifications. Obtaining these certifications can be a complex and time-consuming process, often involving rigorous testing and inspection by accredited third-party organizations. However, it is a necessary step to ensure that the generator set can be legally sold and operated in the target market. Failing to comply with these requirements can result in significant penalties, including fines, product recalls, and reputational damage.

Customization and Adaptability for Diverse Environments

Export quality generator sets aren't just about meeting minimum standards; they often require customization to suit the specific needs and operating conditions of the target market. This can include modifications to the engine, alternator, control panel, or enclosure. For example, generator sets destined for extremely cold climates may require special cold-weather starting systems, including engine heaters and battery warmers. Generator sets operating in dusty or sandy environments may need enhanced air filtration systems to prevent engine damage. In regions with high humidity or corrosive environments, special coatings and materials may be necessary to protect against corrosion. Customization can also extend to the control panel, with options for remote monitoring and control, data logging, and integration with building management systems. Furthermore, the physical enclosure of the generator set may need to be modified to meet specific noise level requirements or to provide enhanced security. The ability to offer a high degree of customization is a key differentiator for manufacturers of export quality generator sets. What unique environmental challenges might your specific export market present?

Logistics and Transportation Considerations

Transporting generator sets across international borders involves a complex web of logistical considerations. The sheer size and weight of these units necessitate careful planning and execution. Packaging must be robust enough to withstand the rigors of ocean freight, air transport, or overland trucking. Specialized crating, often made from reinforced wood or metal, is typically used to protect the generator set from damage during transit. Moisture-resistant barriers and desiccants may be added to prevent corrosion during long sea voyages. Customs clearance procedures can also be complex and time-consuming. Accurate documentation, including commercial invoices, packing lists, and certificates of origin, is essential to avoid delays and penalties. Furthermore, compliance with import regulations in the target market is crucial. This may include obtaining import permits, paying duties and taxes, and complying with specific labeling requirements. Choosing a logistics partner with experience in handling heavy machinery and navigating international trade regulations is essential for ensuring a smooth and efficient transportation process. A breakdown in logistics can lead to costly delays and damage to the generator set, ultimately impacting project timelines and budgets.

Maintenance and After-Sales Support

The long-term reliability and performance of export quality generator sets depend heavily on proper maintenance and after-sales support. Manufacturers should provide comprehensive service manuals, training programs, and readily available spare parts to ensure that operators can properly maintain the equipment. Regular maintenance, including oil changes, filter replacements, and inspections, is essential for preventing breakdowns and extending the life of the generator set. Furthermore, access to qualified service technicians is crucial for troubleshooting and resolving any issues that may arise. Ideally, manufacturers should have a network of authorized service providers in the target market, offering on-site support and repair services. Remote monitoring and diagnostic capabilities can also be valuable, allowing manufacturers to proactively identify potential problems and schedule maintenance before they lead to downtime. A strong commitment to after-sales support is a key differentiator for reputable manufacturers of export quality generator sets, providing customers with peace of mind and ensuring the continued performance of their investment.

Cost-Effectiveness and Return on Investment

While the initial investment in an export quality generator set may be higher than that of a standard unit, the long-term cost-effectiveness and return on investment can be significantly greater. The enhanced reliability, durability, and efficiency of these units translate into lower operating costs, reduced downtime, and extended service life. Fuel efficiency is a key factor in determining the overall cost of ownership. Export quality generator sets are often designed with advanced engine technology and optimized fuel management systems, resulting in lower fuel consumption. Reduced downtime, due to the higher reliability of these units, also contributes to cost savings by minimizing lost production or service interruptions. Furthermore, the longer service life of export quality generator sets means that they can operate for many years, providing a consistent and dependable power source with minimal maintenance requirements. When evaluating the total cost of ownership, it's essential to consider not only the initial purchase price but also the ongoing operating costs, maintenance expenses, and expected lifespan of the generator set. A thorough cost-benefit analysis will often reveal that an export quality generator set represents a more cost-effective investment in the long run. Considering the potential for downtime, how does the initial investment compare to the potential losses?

Future Trends in Export Quality Generator Sets

The field of export quality generator sets is constantly evolving, driven by technological advancements and changing market demands. One key trend is the increasing adoption of hybrid power systems, which combine generator sets with renewable energy sources like solar and wind power. These hybrid systems offer a more sustainable and cost-effective approach to power generation, reducing reliance on fossil fuels and lowering emissions. Another trend is the development of more efficient and environmentally friendly generator sets, incorporating advanced engine technologies, emission control systems, and alternative fuels like biogas and biodiesel. Remote monitoring and control capabilities are also becoming increasingly sophisticated, allowing operators to manage and optimize generator set performance from anywhere in the world. Furthermore, the demand for portable and containerized generator sets is growing, particularly in industries like construction and disaster relief, where rapid deployment and mobility are essential. As technology continues to advance and market needs evolve, export quality generator sets will play an increasingly important role in providing reliable and sustainable power solutions worldwide.

Conclusion: Ensuring Reliable Power Globally

In conclusion, export quality generator sets represent a significant investment in dependable power solutions for businesses and organizations operating across the globe. These generator sets are engineered to meet stringent international standards, withstand challenging environmental conditions, and deliver consistent performance under varying loads. From selecting the right engine and alternator to ensuring compliance with international certifications and providing comprehensive after-sales support, every aspect of the manufacturing and distribution process is carefully considered to ensure the long-term reliability and cost-effectiveness of these units. As the demand for reliable power continues to grow in developing countries and remote regions, export quality generator sets will play an increasingly vital role in supporting economic growth, improving quality of life, and ensuring business continuity.