In industries dealing with flammable gases, combustible dust, or ignitable fibers, ensuring a safe and reliable power supply is paramount. This is where generator sets for hazardous locations become essential. These aren't your standard generators; they are specifically engineered and certified to operate safely in environments where the risk of explosion or fire is significantly higher. Understanding the classification and requirements of these specialized generator sets is crucial for protecting personnel, equipment, and the environment. But what makes a generator suitable for a hazardous location? Let's delve into the intricacies.

Hazardous Location Classifications: Understanding the Zones

The first step in selecting the right generator set is understanding the hazardous location classifications. These classifications, primarily based on the National Electrical Code (NEC) in the United States and the ATEX directives in Europe, categorize hazardous environments based on the type and likelihood of the presence of flammable or combustible materials. The NEC divides hazardous locations into Classes, Divisions, and Groups. Classes define the general nature of the hazardous material (Class I: flammable gases or vapors, Class II: combustible dusts, Class III: ignitable fibers). Divisions indicate the likelihood of the hazardous material being present in an ignitable concentration (Division 1: present continuously, intermittently, or periodically under normal operating conditions; Division 2: present only under abnormal conditions). Groups further categorize the hazardous materials based on their ignition temperature and explosion pressure. European ATEX directives use Zones instead of Divisions, with Zone 0 (or 20 for dust) representing the highest risk and Zone 2 (or 22 for dust) representing the lowest. Correctly identifying the Class, Division (or Zone), and Group is essential for selecting a generator set with the appropriate protection methods. Think of it like choosing the right tool for the job; you wouldn't use a hammer where a screwdriver is needed, and you wouldn't use a standard generator in a hazardous environment.

Protection Methods for Generator Sets in Hazardous Locations

Once the hazardous location classification is determined, the next step is to select a generator set with the appropriate protection method. Several protection methods are employed, each designed to prevent ignition of the hazardous material. One common method is explosion-proof enclosures, which are designed to contain any internal explosion and prevent it from propagating to the surrounding atmosphere. Another method is intrinsic safety, which limits the electrical energy to a level that is incapable of causing ignition. Pressurization, which involves maintaining a positive pressure inside the enclosure to prevent the ingress of flammable materials, is also frequently used. Oil immersion, encapulation, and increased safety are other protection methods. The specific protection method required will depend on the Class, Division (or Zone), and Group of the hazardous location. For example, in a Class I, Division 1 location, explosion-proof enclosures are typically required. It's also worth noting that some generator sets may incorporate multiple protection methods to enhance safety. We ensure that all our generator sets designed for hazardous locations comply with stringent safety standards.

Key Features and Technical Specifications

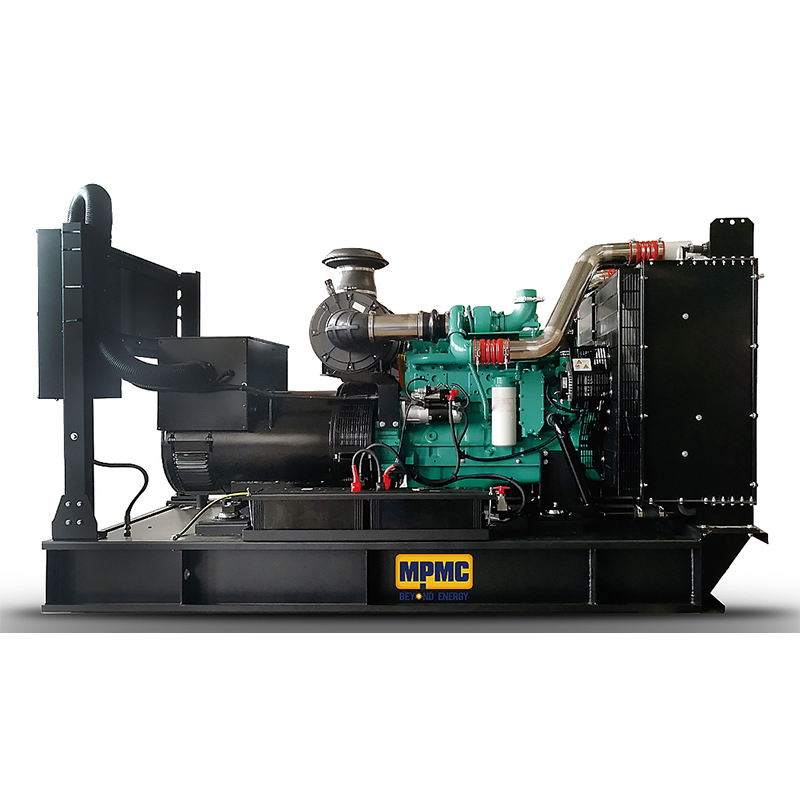

Beyond the protection method, several key features and technical specifications are critical for generator sets in hazardous locations. These include the materials used in construction, the design of electrical components, and the control system. All materials must be compatible with the hazardous environment and resistant to corrosion or degradation. Electrical components must be designed to minimize the risk of sparking or overheating. The control system must be intrinsically safe or housed in an explosion-proof enclosure. Furthermore, the generator set should be equipped with safety features such as overspeed protection, overcurrent protection, and low oil shutdown. Regular inspection and maintenance are also crucial for ensuring the continued safe operation of the generator set. The HS2000Ex model, for example, boasts a robust design and utilizes explosion-proof enclosures certified to meet stringent international standards. This model is frequently deployed in offshore oil platforms and chemical processing plants.

Performance Parameters and Reliability

Performance parameters and reliability are just as important as safety features in hazardous location generator sets. The generator set must be capable of providing a stable and reliable power supply under the demanding conditions of a hazardous environment. This includes factors such as voltage regulation, frequency stability, and load-carrying capacity. Reliability is paramount, as downtime in a hazardous location can have severe consequences. Therefore, the generator set should be designed with high-quality components and undergo rigorous testing to ensure its ability to operate continuously and reliably. Our company utilizes advanced manufacturing techniques and quality control processes to ensure the highest levels of reliability in our generator sets. We also offer comprehensive maintenance programs to keep the generator sets in optimal operating condition. What kind of backup power solution are you really looking for when system failure is not an option?

Application Scenarios and Problem Solving

Generator sets for hazardous locations find applications in a wide range of industries, including oil and gas, chemical processing, mining, and pharmaceuticals. In the oil and gas industry, they are used to power critical equipment on offshore platforms and onshore drilling sites. In chemical processing plants, they provide backup power for safety systems and process control equipment. In mining operations, they are used to power ventilation systems and emergency lighting. In pharmaceuticals, they ensure the continuous operation of critical equipment used in the production of life-saving medications. A common problem solved by these generator sets is the need for a reliable power source in areas where the risk of explosion or fire is high. Standard generators are simply not an option in these environments, making certified hazardous location generator sets essential. These generator sets allow industries to operate safely and efficiently, even in the most challenging environments. Consider the potential costs and risks of *not* investing in a properly classified generator set.

Quality Standards and Certifications

Quality standards and certifications are paramount for generator sets designed for hazardous locations. These certifications provide assurance that the generator set has been tested and meets the stringent safety requirements for its intended application. Common certifications include UL (Underwriters Laboratories) listing, ATEX certification, and IECEx certification. UL listing is widely recognized in North America and indicates that the generator set has been tested to UL safety standards. ATEX certification is required for equipment used in hazardous locations in Europe and demonstrates compliance with the ATEX directives. IECEx certification is an international certification scheme that covers equipment used in explosive atmospheres. Obtaining these certifications requires rigorous testing and evaluation by accredited third-party organizations. When choosing a generator set for a hazardous location, it is crucial to ensure that it is certified by a reputable organization. Our HS2000Ex model has achieved multiple certifications, providing our clients with the assurance that it meets the highest safety standards. Contact us to learn more about specific certifications and our compliance processes.

Customization and Flexibility

While standard generator sets for hazardous locations are available, many applications require customized solutions to meet specific needs. Customization options can include modifications to the enclosure, the control system, the fuel system, and the exhaust system. For example, a client may require a generator set with a specific voltage or frequency, or a generator set that can operate on a different type of fuel. Customization can also involve integrating the generator set with existing systems or providing specialized controls for remote monitoring and operation. Our company offers flexible customization options to meet the unique requirements of our clients. We work closely with our clients to understand their specific needs and develop customized solutions that provide optimal performance and reliability. Whether it's a small modification or a complete redesign, we have the expertise and capabilities to deliver a generator set that meets your exact requirements. We understand that needs vary widely, which is why we are prepared to deliver solutions for both business wholesale and individual purchase orders.

Purchase Information and After-Sales Support

Our company provides comprehensive purchase information and after-sales support to ensure a smooth and satisfactory experience for our clients. We offer flexible order quantity options to accommodate both business wholesale and individual purchase needs. Samples are available for evaluation, allowing clients to test the generator set before making a large purchase. Our after-sales support includes installation assistance, training, maintenance services, and technical support. We have a team of experienced technicians who are available to provide on-site support and troubleshooting. We also offer a comprehensive warranty on our generator sets, providing peace of mind and protection against defects in materials and workmanship. Our diverse payment options make it easy for clients to purchase the generator sets they need. We believe in building long-term relationships with our clients and are committed to providing exceptional service and support throughout the entire lifecycle of the generator set. Do you have a specific project in mind that requires reliable and certified power? What sort of follow-up services are critical to your ongoing success?

Generator sets designed for hazardous locations are indispensable assets for industries operating in environments fraught with explosion and fire hazards. Their stringent safety requirements, meticulous classification, and robust construction are vital for safeguarding personnel and equipment. From the HS2000Ex model to customized solutions, understanding these specialized systems enables secure and efficient operation in challenging landscapes. Our commitment extends to delivering not only high-quality, certified products but also flexible customization options and comprehensive after-sales support. This commitment underscores our dedication to providing safe, reliable, and adaptable power solutions. For more detailed information, please visit our official website: https://www.hsgeneratorset.com