Inside the Engine Room: A Deep Dive into the Power Generator Factory

Have you ever stopped to think about where the reliable hum of power comes from when the grid flickers out? It’s a question that often crosses my mind, especially during those unexpected outages. The answer, frankly speaking, lies within the sophisticated operations of a power generator factory. These aren't just assembly lines; they are intricate ecosystems where raw materials are transformed into the dependable lifelines that keep our homes, businesses, and critical infrastructure running. In my experience, understanding the journey of a generator from concept to completion offers a profound appreciation for the technology and human ingenuity involved.

The Genesis of Reliability: Design and Engineering at the Factory

Before a single bolt is tightened or a wire is connected, the journey of a power generator begins in the design and engineering departments of a power generator factory. This is where innovation meets practicality. Engineers meticulously craft specifications, considering factors like power output, fuel efficiency, noise levels, and environmental impact. They utilize advanced CAD (Computer-Aided Design) software to model every component, ensuring optimal performance and durability. It's worth noting that the selection of materials is crucial here. High-grade steel for the frame, specialized alloys for engine parts, and robust insulation for electrical components are chosen based on rigorous testing and industry standards. The goal is to create a product that not only meets but exceeds the demands of various applications, from residential backup to large-scale industrial power solutions.

The engineering team also plays a vital role in developing different types of generators. Whether it's a diesel generator for continuous industrial use, a natural gas generator for cleaner emissions, or a portable generator for emergency preparedness, each design requires a unique approach. They consider the operating environment, the expected load, and the regulatory requirements that the generator will need to comply with. This phase is all about laying a solid foundation for a reliable and efficient product.

From Components to Core: The Assembly Line Unveiled

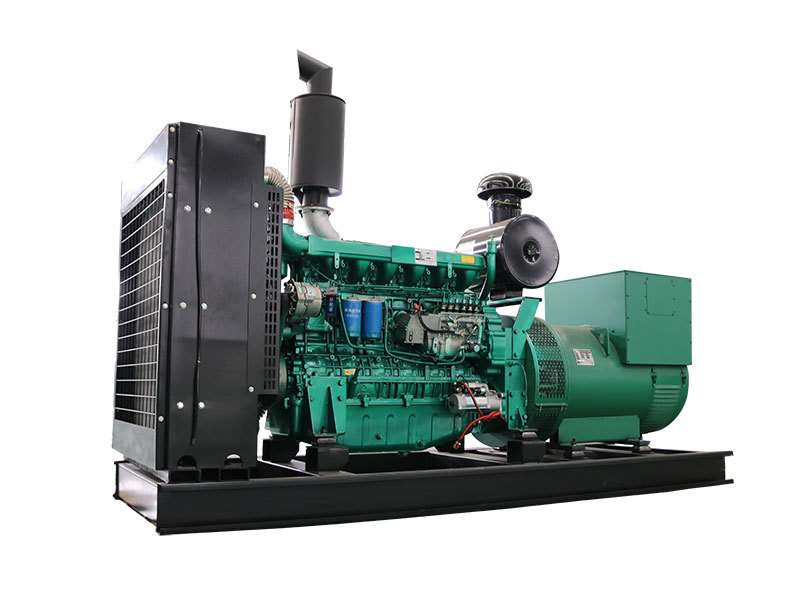

Stepping onto the factory floor is like entering a symphony of precision. The assembly line is where the meticulously designed components come together. This is the heart of the power generator factory, a place where skilled technicians and automated machinery work in tandem. The process typically begins with the chassis or frame, which provides the structural integrity for the entire unit. Following this, the engine – the powerhouse of the generator – is carefully installed. This is often a complex operation, requiring specialized lifting equipment and precise alignment.

Next comes the alternator, the component responsible for converting mechanical energy from the engine into electrical energy. Its integration with the engine is critical for efficient power generation. Then, the fuel system, cooling system, and exhaust system are meticulously fitted. Each connection, each seal, and each component is handled with extreme care. Interestingly enough, modern factories often employ robotic arms for repetitive or heavy tasks, ensuring consistency and reducing the risk of human error. However, the intricate electrical wiring and final quality checks still rely heavily on the expertise of human technicians.

The electrical control panel is another vital area of assembly. This is the brain of the generator, housing the automatic transfer switch (ATS), voltage regulators, circuit breakers, and monitoring systems. Technicians carefully wire these components, ensuring that the generator can seamlessly switch on during an outage and safely deliver power. The attention to detail here is paramount, as even a minor wiring error can compromise the entire system's functionality.

Quality Assurance: The Unwavering Commitment to Excellence

In any manufacturing facility, quality control is king, but in a power generator factory, it’s practically royalty. The stakes are incredibly high; a faulty generator can lead to significant financial losses, disruptions to essential services, and even safety hazards. Therefore, rigorous testing is integrated at multiple stages of the production process.

Upon completion of the assembly, each generator undergoes a series of comprehensive tests. These typically include:

- Load Testing: Generators are run under various load conditions, from no load to full load, to ensure they can consistently deliver the rated power output without overheating or faltering.

- Voltage and Frequency Stability Tests: Technicians verify that the generator maintains stable voltage and frequency outputs, which are crucial for sensitive electronic equipment.

- Start-up and Shutdown Sequence Tests: The automatic transfer switch (ATS) functionality is tested to ensure it correctly detects power outages and initiates the generator's start-up sequence.

- Noise and Vibration Analysis: Generators are tested to ensure they meet specified noise and vibration limits, especially for applications in residential areas or noise-sensitive environments.

- Emissions Testing: For generators that need to comply with environmental regulations, emissions are carefully monitored and measured.

It's not uncommon for generators to undergo hundreds of hours of testing before they are deemed ready for shipment. This unwavering commitment to quality assurance is what builds trust and ensures that customers receive a product they can rely on when it matters most. Many experts agree that this meticulous approach is what differentiates a top-tier generator manufacturer from the rest.

Innovation and Future Trends in Generator Manufacturing

The world of power generation is constantly evolving, and power generator factories are at the forefront of this innovation. We're seeing a significant push towards more sustainable and intelligent solutions. For instance, the development of hybrid generators that combine traditional fuel sources with battery storage is gaining traction. These systems offer improved fuel efficiency and reduced emissions, providing a more environmentally friendly option for backup power.

Furthermore, the integration of advanced control systems and IoT (Internet of Things) technology is transforming how generators are monitored and managed. Smart generators can now communicate their status, performance data, and maintenance needs remotely. This allows for predictive maintenance, minimizing downtime and ensuring that the generator is always ready to perform. Have you ever thought about a generator that can tell you it needs service before it even breaks down? That's the future we're moving towards.

Another area of active development is the exploration of alternative fuels. While diesel and natural gas remain dominant, research into hydrogen fuel cells and advanced biofuels for generator applications is ongoing. The goal is to provide reliable power with an even smaller environmental footprint. The industrial generator production sector is actively investing in R&D to meet these emerging demands.

The Global Impact of Power Generator Factories

Frankly speaking, the impact of a well-functioning power generator factory extends far beyond its immediate vicinity. These factories are crucial for ensuring the stability of our modern infrastructure. From hospitals that rely on uninterrupted power for life-saving equipment to data centers that keep our digital world running, backup power solutions are indispensable. The production of reliable emergency power systems is a critical component of national security and economic resilience.

Moreover, these factories contribute significantly to the economy by creating jobs, fostering technological advancements, and supporting a vast supply chain of component manufacturers and service providers. The skilled workforce within these facilities, from engineers and technicians to assembly line workers and quality control specialists, represents a vital segment of the industrial sector. The ongoing demand for robust backup power solutions ensures that these factories will continue to play a pivotal role in shaping our powered future.

The journey from raw materials to a fully functional power generator is a testament to human ingenuity and industrial prowess. The next time you hear the reassuring hum of a generator kicking in, remember the complex processes and dedicated people within the power generator factory that made it possible.

For more detailed information, please visit our official website:Power generator factory

About the author: Meet Anya Sharma, a seasoned industrial journalist with over a decade of experience exploring the intricacies of manufacturing. Anya has a keen interest in the engineering behind essential technologies, particularly those that ensure operational continuity and safety in critical sectors. Her insights into power generation and industrial processes are sought after by industry leaders and enthusiasts alike.