Powering Progress: Understanding Generator Set Power Output Requirements for Plants

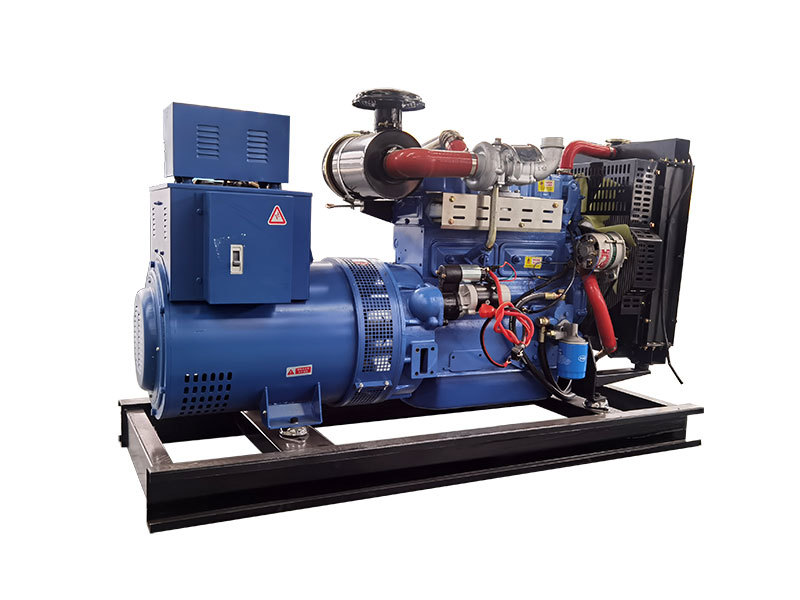

In the complex world of industrial operations, reliable power is not just a convenience; it's the lifeblood that keeps everything running smoothly. When we talk about plants – whether they're manufacturing facilities, data centers, or even critical infrastructure hubs – the need for uninterrupted power is paramount. This is where generator sets come into play, acting as the ultimate safety net against grid failures. But how do you ensure you're selecting the right generator set power output requirements for plants? It's a question that demands careful consideration, a deep dive into your operational needs, and a solid understanding of the technology involved. Frankly speaking, getting this wrong can lead to costly downtime, damaged equipment, and significant operational disruptions.

Assessing Your Plant's True Power Demands

Before you even start looking at generator specifications, the most crucial step is to thoroughly assess your plant's power demands. This isn't a superficial glance; it requires a detailed analysis of every piece of equipment, every process, and every potential scenario. Many plant managers underestimate the complexity of this assessment, leading to undersized or oversized generator solutions. In my experience, a comprehensive load bank study is invaluable here. This involves simulating your plant's maximum power draw under various operating conditions.

You need to identify your critical loads. These are the systems and equipment that absolutely must remain operational during a power outage. Think about emergency lighting, critical control systems, safety equipment, essential manufacturing machinery, and IT infrastructure. These are the loads that will dictate the minimum continuous power output your generator set needs to provide.

Beyond critical loads, consider your non-critical loads. These are the systems that can be shut down or phased in after the critical ones are stable. Understanding the difference allows for more efficient generator sizing and cost management. It's worth noting that the starting surge current for some equipment, like large motors, can be significantly higher than their running current. This 'inrush' power must also be factored into your generator set power output requirements for plants.

The Importance of Load Profiling

Load profiling is the process of mapping out your plant's power consumption over a typical operational cycle. This helps you understand not just the peak demand but also the average demand and how it fluctuates. A generator that's sized only for peak demand might be unnecessarily large and inefficient during normal operation. Conversely, one sized only for average demand might struggle during peak periods.

Have you ever wondered how a plant keeps running even when the main power goes out? It’s all about having the right backup. This involves a detailed understanding of what needs power, when, and for how long. The generator set power output requirements for plants are directly derived from this meticulous load analysis.

Key questions to ask during load profiling:

- What is the maximum simultaneous power draw of all critical equipment?

- What are the starting surge requirements for motors and other inductive loads?

- What is the typical power consumption profile throughout a 24-hour period?

- Are there any future expansion plans that might increase power demands?

Understanding Generator Set Specifications: Power Ratings Explained

Once you have a clear picture of your power needs, you can start looking at generator sets. The specifications can seem daunting, but understanding the key power ratings is essential for meeting your generator set power output requirements for plants.

Prime vs. Standby Power Ratings

Generators are typically rated in two main ways: prime power and standby power. It's vital to know the difference:

- Standby Power Rating (ESP - Emergency Standby Power): This is the maximum power the generator can deliver for a limited duration during a utility power failure. It's usually rated at a specific average load over a year (e.g., 200 hours). This is often the rating you'll see advertised, but it's crucial to understand its limitations.

- Prime Power Rating (PRP - Prime Power Rating): This is the maximum power the generator can deliver continuously under variable load conditions. This rating is more relevant for applications where the generator might be used for extended periods or as a primary power source, though for backup purposes, it represents a more robust capability.

For most plant backup applications, you'll be looking at the standby power rating, but you must ensure it comfortably exceeds your critical load requirements, accounting for that inrush current. Many experts agree that oversizing slightly is often better than undersizing when it comes to critical power.

Kilowatts (kW) vs. Kilovolt-Amperes (kVA)

You'll also encounter ratings in kW and kVA. These are related but not the same. Kilowatts (kW) represent the real power delivered to the load, essentially the useful work done. Kilovolt-amperes (kVA) represent the apparent power, which includes both real power and reactive power (needed by inductive loads like motors). The relationship between them is defined by the power factor (PF).

kVA x Power Factor = kW

Most generators have a power factor of around 0.8. This means a 100 kVA generator can typically deliver 80 kW of real power. When specifying generator set power output requirements for plants, it's essential to match the generator's kW output to your plant's kW demand, while also ensuring the kVA rating is sufficient to handle the reactive power components of your loads.

Sizing Your Generator Set: Beyond Simple Calculations

Sizing a generator set isn't just about adding up the kW ratings of your critical equipment. Several other factors come into play, making the process more nuanced than it might initially appear.

Load Type and Starting Requirements

As mentioned, starting surge currents are a major consideration. A motor might draw 5-7 times its running current when it starts. If your generator set can't handle this initial surge, it might trip, or worse, fail to start the equipment. This is where understanding the specific starting characteristics of your plant's motors and other inductive loads is critical.

Generator sizing tools and software are often used by professionals to accurately model these starting surges and ensure the generator can cope. Many experts agree that a detailed motor starting study is a non-negotiable part of accurately determining generator set power output requirements for plants.

Altitude and Temperature Derating

The performance of a generator set is affected by its operating environment. Higher altitudes mean thinner air, which reduces engine cooling efficiency and power output. Similarly, higher ambient temperatures can also lead to derating. Manufacturers provide derating factors that you must apply to the generator's rated output based on your plant's specific location and typical environmental conditions. Failing to account for derating can result in a generator that's underperforming when you need it most.

Future Expansion and Redundancy

It's wise to consider future growth. Will your plant's power needs increase in the next 5-10 years? Sizing a generator with some headroom for future expansion can save you the significant cost and disruption of replacing it later. Furthermore, for extremely critical operations, you might consider redundant generator systems. This involves having multiple generators that can either share the load or one can take over if the other fails, providing an extra layer of resilience.

Interestingly enough, many plants opt for a N+1 or 2N redundancy configuration for their critical power systems. This ensures that even if one component fails, the entire operation doesn't grind to a halt.

Selecting the Right Generator Technology and Features

Beyond raw power output, the type of generator and its features are important considerations for your plant's specific needs.

Diesel vs. Natural Gas Generators

The most common types are diesel and natural gas generators. Diesel generators are known for their robustness, high power density, and reliability, making them a popular choice for standby power. Natural gas generators offer lower emissions and potentially lower fuel costs if natural gas is readily available and cost-effective. However, they typically have a slightly lower power density and may require a constant gas supply, which could be interrupted in certain disaster scenarios.

The choice often depends on fuel availability, cost, environmental regulations, and the required runtime. For extended outages, fuel storage for diesel generators becomes a critical factor. For many industrial applications, the robust nature of diesel engines makes them the preferred choice for meeting stringent generator set power output requirements for plants.

Transfer Switches and Control Systems

An automatic transfer switch (ATS) is a crucial component that automatically detects a loss of utility power and signals the generator to start, then transfers the load to the generator. When utility power is restored, the ATS transfers the load back and signals the generator to shut down. The speed and reliability of your ATS are critical for minimizing downtime.

Modern generator sets come with sophisticated control systems that monitor performance, manage load shedding, provide diagnostic information, and allow for remote monitoring. These control systems are vital for ensuring the generator operates efficiently and reliably, and for troubleshooting any issues that may arise.

Fuel Storage and Maintenance

For diesel generators, adequate fuel storage is a must. You need enough fuel to run your critical loads for a specified period, often 24 hours or more. Regular maintenance is also non-negotiable. This includes regular testing, oil changes, filter replacements, and battery checks. A well-maintained generator is far more likely to perform when you need it most. Frankly speaking, neglecting maintenance is a direct invitation to failure.

Many plant managers I've spoken with emphasize the importance of a proactive maintenance schedule. It's an investment that pays dividends in reliability and longevity.

Conclusion: Ensuring Uninterrupted Operations

Selecting the correct generator set power output requirements for plants is a critical decision that impacts operational continuity, safety, and profitability. It’s a process that demands a thorough understanding of your plant’s unique power needs, a careful evaluation of generator specifications, and consideration of environmental factors and future growth. By investing time in detailed load analysis, understanding power ratings, and considering advanced features, you can ensure your plant is equipped with a reliable backup power solution.

Remember, the goal is not just to buy a generator, but to implement a robust power strategy that safeguards your operations against the unpredictable. Don't hesitate to consult with power generation specialists and engineers to help you navigate the complexities and make the most informed decision for your specific plant requirements. Getting the generator set power output requirements for plants right is a cornerstone of operational resilience.

For more detailed information, please visit our official website:generator set power output

About the author: Alex Chen is a seasoned electrical engineer with over 15 years of experience in industrial power systems and backup generation solutions. He specializes in assessing complex power demands for manufacturing facilities and critical infrastructure, ensuring optimal generator sizing and system integration. Alex is passionate about helping businesses achieve uninterrupted operations through reliable and efficient power management strategies.