Beyond the Engine: What to Look for in a Top Generator Set Manufacturer

In our hyper-connected, always-on world, power isn't just a convenience; it's the lifeblood of commerce, safety, and modern life. From data centers processing billions of transactions to hospitals where electricity means the difference between life and death, a reliable power source is non-negotiable. This is where generator sets, or gensets, come in. But here’s a critical truth that many overlook: the performance and reliability of your generator set are almost entirely dependent on the quality of the company that built it. Choosing the right generator set manufacturer is one of the most crucial infrastructure decisions you'll ever make.

Frankly speaking, it's easy to get lost in a sea of specifications—kilowatts, engine brands, and fuel types. While these are important, they only tell part of the story. A truly exceptional manufacturer offers more than just a product; they provide a partnership, a promise of reliability, and a comprehensive power solution engineered for your specific needs. So, how do you distinguish a mere assembler from a world-class manufacturing partner? Let's dive deep into the factors that truly matter.

What Truly Defines a Premier Generator Set Manufacturer?

Have you ever stopped to think about what goes into building a machine that can power an entire factory during an outage? It's far more complex than simply bolting an engine to an alternator and putting it in a box. A premier manufacturer orchestrates a symphony of engineering, sourcing, and quality control. In my experience, the best companies distinguish themselves in a few key areas.

Engineering Excellence and In-House Expertise

The foundation of any great genset is its design. A top-tier manufacturer doesn't just follow a standard blueprint; they innovate. This means having a dedicated team of mechanical and electrical engineers who live and breathe power generation. They are the ones who:

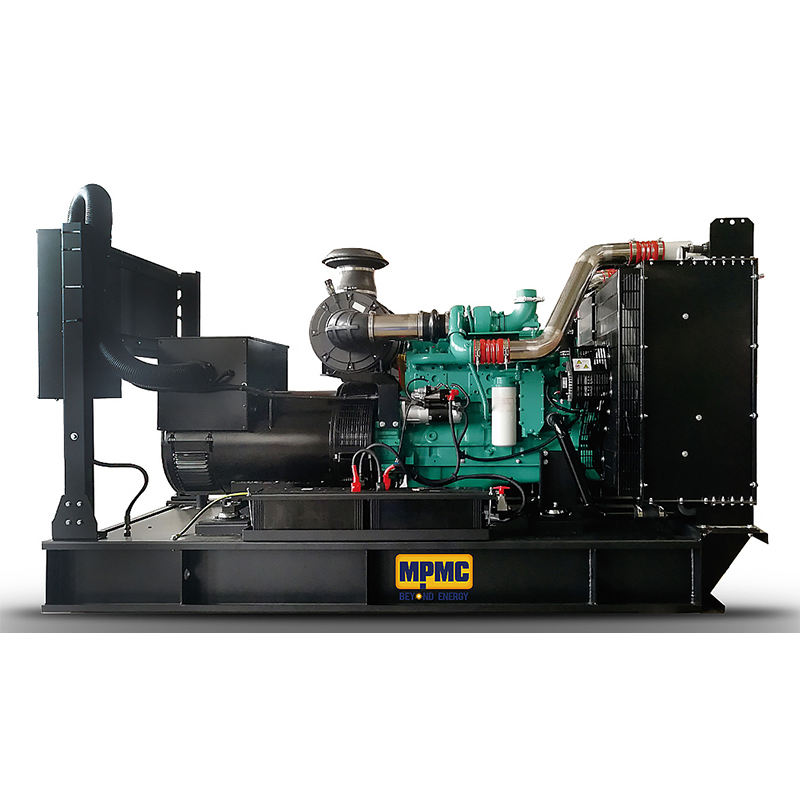

- Optimize performance: They meticulously match world-class engines (like Perkins, Cummins, or MTU) with high-performance alternators (like Stamford or Leroy-Somer) to create a perfectly balanced and efficient system.

- Design for durability: They consider factors like vibration dampening, airflow for cooling, and structural integrity of the base frame and enclosure. It's the small details that prevent catastrophic failures down the line.

- Integrate advanced controls: The "brain" of the genset is the control panel. Leading manufacturers develop or integrate sophisticated controllers that allow for remote monitoring, automatic transfer switching, and even complex paralleling with other generators or the grid.

A Comprehensive and Versatile Product Range

A manufacturer's product catalog is a direct reflection of their capabilities and understanding of the market. While some may specialize in a narrow niche, a truly versatile partner can cater to a wide array of applications. This includes offering a broad selection of industrial diesel generator sets, which remain the workhorse for most standby and prime power applications due to their reliability and fuel efficiency. However, a forward-thinking company will also provide options for:

- Natural Gas Gensets: Ideal for applications with a continuous fuel supply, offering lower emissions and often lower operating costs.

- Bi-Fuel and Hybrid Systems: These innovative solutions combine the best of different technologies for enhanced efficiency and environmental compliance.

- A Wide Power Spectrum: From a compact 30 kVA unit for a small business to a massive 3000 kVA behemoth for a data center, the ability to provide solutions across the entire power range is a sign of a mature and capable manufacturer.

Unyielding Adherence to Global Standards

Certifications aren't just fancy logos on a brochure; they are your assurance of safety, quality, and performance. A reputable manufacturer will proudly display their adherence to internationally recognized standards. It's worth noting that these certifications require rigorous audits and a deep commitment to process excellence. Key standards to look for include:

- ISO 9001: This demonstrates a commitment to quality management systems, ensuring consistency and continuous improvement in their processes.

- ISO 14001: This shows a commitment to environmental management, crucial in today's eco-conscious world.

- CE Marking / UKCA Marking: Essential for products sold in Europe and the UK, indicating compliance with health, safety, and environmental protection standards.

- UL 2200: A critical safety standard for stationary engine generator assemblies in North America.

To be honest, a manufacturer that invests in these certifications is investing in you, the customer. It shows they aren't cutting corners and are committed to delivering a product you can trust implicitly.

The Critical Role of Customization and Application-Specific Solutions

One of the biggest mistakes a buyer can make is assuming a standard, off-the-shelf generator will perfectly meet their needs. Every application has unique challenges, whether it's extreme temperatures, high altitudes, strict noise regulations, or limited space. This is where a manufacturer's ability to provide custom power generation solutions becomes a game-changer.

Deeply Understanding Your Power Needs

Before a single bolt is turned, a great manufacturing partner starts with a conversation. They act as consultants, seeking to understand the intricacies of your operation. This discovery process should cover:

- Load Profile Analysis: What kind of equipment will the generator be powering? Are there large motors that cause significant starting current (inrush)? A proper load analysis ensures the generator is sized correctly—not too small to handle the load, and not so large that it runs inefficiently.

- Environmental Conditions: A generator operating in the heat of the Dubai desert requires a different cooling system than one installed in the frigid Canadian north. Altitude also plays a huge role, as it can de-rate an engine's power output.

- Industry-Specific Requirements: A hospital requires ultra-fast, reliable transfer of power and often has strict noise and emission limits. A construction site needs a rugged, portable unit. A data center demands flawless integration for N+1 or 2N redundancy. The manufacturer must speak your industry's language.

Tailoring the Genset to Perfection

Once your needs are understood, the customization process begins. This is where engineering expertise truly shines. A top-tier manufacturer can tailor almost every aspect of the genset, including:

- Custom Enclosures: Beyond standard weather-proofing, they can design super-silent (acoustic) enclosures for noise-sensitive areas like residential neighborhoods or hospitals, or build enclosures from special materials like stainless steel for corrosive environments.

- Advanced Fuel Systems: This can include oversized base tanks for extended run times, dual-wall tanks for environmental protection, or complex fuel polishing and transfer systems.

- Sophisticated Paralleling Switchgear: For large or critical projects, multiple generators often need to work together seamlessly. Designing and building the switchgear that manages load sharing, synchronization, and redundancy is a highly specialized skill that separates the experts from the amateurs.

Evaluating a Manufacturer's Production and Quality Control

An incredible design is meaningless if it can't be executed flawlessly on the factory floor. The manufacturing process is where reliability is forged. When you're choosing a generator supplier, you're not just buying the final product; you're buying into their entire production philosophy.

From Raw Materials to Final Assembly

Quality starts with the components. A reputable manufacturer has an incredibly stringent supply chain. They don't just source engines and alternators from top brands; they vet every single component, from the steel used for the base frame to the wiring and circuit breakers in the control panel. Many experts agree that this level of control is paramount. They maintain strong relationships with their suppliers and have processes to ensure every part meets their exacting standards.

The Gauntlet of Testing: Your Ultimate Peace of Mind

This is, without a doubt, one of the most critical stages. Before a generator ever leaves the factory, it should be subjected to a battery of rigorous tests to verify its performance and reliability. A serious generator set manufacturer will have a dedicated testing facility and a transparent process. Key tests include:

- Factory Acceptance Test (FAT): This is a comprehensive test witnessed by the customer or their representative. The generator is run and its performance is measured against the specified requirements.

- Load Bank Testing: This is the only way to prove a generator can handle its rated load. The genset is connected to a large load bank that simulates the electrical load it will see in the real world. It's typically tested at various load steps (e.g., 25%, 50%, 75%, 100%, and even 110% for a short period) to ensure it performs flawlessly under pressure.

- Full System Verification: All safety features, control functions, and alarms are tested to ensure they work as designed.

A manufacturer who is confident in their product will be more than happy to have you witness these tests. In fact, they'll insist on it. It’s the ultimate proof of their commitment to quality.

After-Sales Support: The Partnership That Powers Your Future

The relationship with your manufacturer shouldn't end when the generator is delivered. To be honest, that's when the most important phase begins. A generator set is a long-term asset that requires proper installation, maintenance, and support to deliver reliable power for its entire lifespan, which can be decades.

Expert Installation and Commissioning

Proper installation is critical for safety and performance. A great manufacturer or their certified local partner will have a team of technicians who can handle the entire commissioning process. This includes ensuring the generator is placed on a proper foundation, ventilation is adequate, and all electrical and fuel connections are made correctly and safely. They perform on-site testing to ensure the system works perfectly within your facility's infrastructure.

The Lifeline of Technical Support and Spare Parts

When a power outage hits and your generator is your only line of defense, who are you going to call? A top manufacturer provides 24/7 technical support with experts who can help diagnose issues over the phone. Furthermore, they maintain a large inventory of genuine spare parts. Using genuine parts is crucial; they are designed to fit perfectly and perform to the original specification, ensuring the long-term health of your investment. I've found that the availability and speed of parts delivery is a massive differentiator between average and excellent suppliers.

Comprehensive Warranty and Maintenance Programs

A strong warranty is a statement of confidence from the manufacturer in their own product. Look for a comprehensive warranty that covers all major components. Beyond the warranty, inquire about their service and maintenance agreements. Regular, preventative maintenance performed by certified technicians is the single best way to ensure your generator will start and run when you need it most. These programs are designed to catch small issues before they become major, costly failures.

Ultimately, selecting a power partner is a decision that extends far beyond the initial purchase price. It’s an investment in operational continuity, safety, and peace of mind. By looking beyond the engine and evaluating a company's engineering depth, customization capabilities, manufacturing quality, and long-term support, you can forge a partnership that will power your success for years to come. Your choice of generator set manufacturer isn't just a line item on a budget; it's the foundation of your resilience.

For more detailed information, please visit our official website:Generator set manufacturer

About the author: David Chen is a Senior Power Systems Engineer with over 15 years of experience in designing and implementing critical power infrastructure for data centers, healthcare facilities, and industrial complexes. He specializes in custom generator set applications and is passionate about helping organizations build resilient and efficient power solutions. David holds a Master's degree in Electrical Engineering and is a certified power generation technician who enjoys demystifying complex engineering topics for a broader audience.