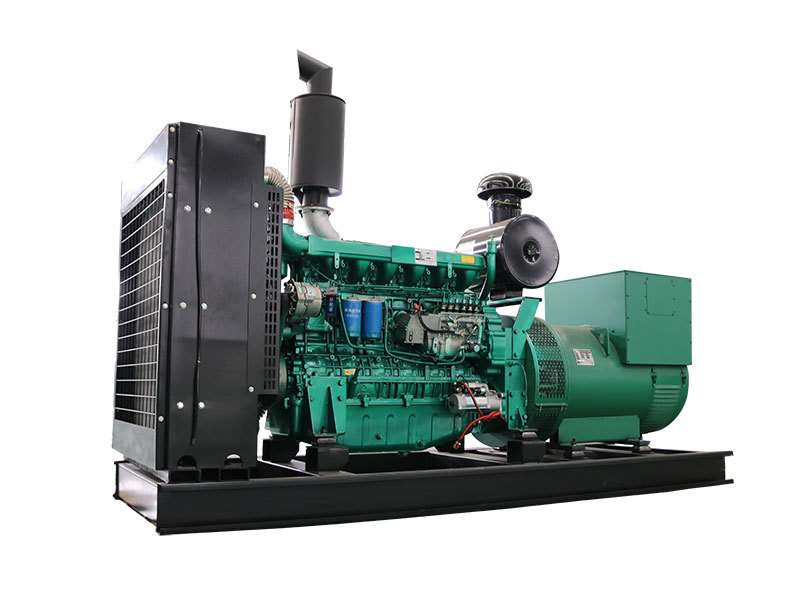

Demystifying Your Industrial Generator Set Price Quote: A Comprehensive Guide

In today's interconnected and increasingly power-dependent world, the reliability of your industrial operations hinges significantly on a robust and dependable power supply. For many businesses, this means investing in an industrial generator set. But, to be honest, navigating the market to get an accurate industrial generator set price quote can feel like a complex maze. It’s not just about the sticker price; it’s about understanding the myriad factors that contribute to the overall cost, ensuring you make an investment that truly meets your operational needs and budget.

Have you ever wondered what truly goes into an industrial generator set price quote? It's far more intricate than simply picking a model off a shelf. From power output and fuel type to installation complexities and long-term maintenance, every element plays a crucial role in the final figure. This comprehensive guide aims to shed light on these factors, helping you understand the true value behind the numbers and empowering you to make an informed decision for your business. Let's delve into what you need to know to secure the best industrial generator set price quote.

Key Factors Influencing Your Industrial Generator Set Price Quote

Frankly speaking, the initial industrial generator set price quote you receive is a composite of many variables. Understanding these components is paramount to evaluating different offers and ensuring you're comparing apples to apples. Many experts agree that overlooking even one of these elements can lead to unexpected costs down the line.

Power Output (kVA/kW)

This is, without a doubt, the most significant determinant of your industrial generator set price quote. Generators are rated in kilovolt-amperes (kVA) or kilowatts (kW), representing their capacity to produce electricity. The higher the power requirement of your facility, the larger and more powerful the generator needed, and consequently, the higher the cost. It's crucial to conduct a thorough load assessment of your facility to determine the exact power output you require. Over-specifying can lead to unnecessary expense, while under-specifying can result in insufficient power during outages, potentially damaging equipment or halting operations. In my experience, a slight buffer is always a good idea, but don't go overboard.

Fuel Type (Diesel, Natural Gas, Propane)

The choice of fuel significantly impacts not only the initial industrial generator set price quote but also the long-term operational costs.

- Diesel Generators: Historically the most common for industrial applications due to their reliability, durability, and fuel efficiency under heavy loads. Diesel generators often have a higher upfront cost compared to gas units of similar power, but their fuel consumption can be more efficient, especially for prime power or long-duration standby. The cost of industrial power generator units running on diesel can also be influenced by local fuel prices and storage requirements.

- Natural Gas Generators: These are becoming increasingly popular, especially where a natural gas line is readily available. They offer continuous fuel supply without the need for on-site storage, leading to lower refueling logistics. While the initial purchase price might be slightly lower than comparable diesel units, their fuel efficiency can be less for certain load profiles.

- Propane Generators: Less common for very large industrial applications but viable for medium-sized needs. Propane is a clean-burning fuel that can be stored on-site. However, its energy density is lower than diesel, meaning larger tanks are needed for equivalent run times, and the fuel cost per kWh can be higher.

Generator Type (Standby, Prime, Portable)

The intended use of the generator also plays a big role in the industrial generator set price quote.

- Standby Generators: Designed to automatically kick in when the main power supply fails. They are typically installed permanently and are built for reliability during emergencies. The industrial standby generator cost tends to be higher due to features like automatic transfer switches (ATS) and robust control systems.

- Prime Power Generators: Used as the primary source of power in remote locations or where grid power is unavailable. These units are built for continuous, heavy-duty operation and are engineered for longer lifespans and more rigorous use, reflecting in their higher price.

- Portable Industrial Generators: While some large portable units exist for construction sites or events, they are generally smaller and less robust than permanent standby or prime power units, and thus, typically less expensive.

Engine Brand and Components

Just like with vehicles, the brand of the engine and the quality of its components significantly affect the price. Reputable engine manufacturers (e.g., Cummins, Perkins, MTU, Caterpillar, Volvo) are known for their reliability, efficiency, and global support networks, which naturally command a higher price. Investing in a well-known brand often translates to better performance, longer lifespan, and easier access to spare parts and service.

Enclosure and Sound Attenuation

An open-frame generator is the cheapest option, but it offers no protection from the elements and produces significant noise. Most industrial applications require a weather-proof enclosure to protect the unit from rain, dust, and extreme temperatures. For urban or noise-sensitive environments, a sound-attenuated enclosure is essential. These enclosures add to the industrial generator set price quote, but they are often a necessary investment for compliance and operational comfort.

Control Panel and Monitoring Systems

The sophistication of the control panel varies widely. Basic panels offer manual start/stop and essential readings, while advanced digital controllers provide automatic operation, remote monitoring, fault diagnostics, and integration with building management systems. These advanced features, while adding to the upfront industrial generator set price quote, can significantly improve operational efficiency, reduce downtime, and simplify maintenance.

Emissions Regulations and Compliance

Depending on your location, generators must comply with specific emissions standards (e.g., EPA Tier ratings in the US). Meeting stricter emissions regulations often requires more advanced engine technology, exhaust after-treatment systems (like DPFs or SCRs), which can substantially increase the generator's cost. It's crucial to understand local environmental regulations before requesting an industrial generator set price quote.

Beyond the Initial Industrial Generator Set Price Quote: Hidden Costs and Long-Term Value

Interestingly enough, the price tag on the generator itself is just one piece of the puzzle. When evaluating an industrial generator set price quote, it's vital to consider the total cost of ownership (TCO). Many experts agree that failing to account for these additional expenses can lead to significant budget overruns.

Installation and Commissioning

This is often a substantial part of the overall investment. Installation involves site preparation (concrete pad, fencing), electrical work (cabling, conduit, connections to the ATS and main electrical panel), fuel line installation, exhaust system routing, and potentially a cooling system. Commissioning ensures the generator is properly integrated, tested, and ready for operation. The complexity and cost of installation vary greatly depending on the generator's size, location, and existing infrastructure.

Fuel Storage and Delivery Systems

For diesel and propane generators, you'll need appropriate fuel storage tanks, which must comply with local fire and environmental codes. This includes the tank itself, pumps, piping, and potentially spill containment measures. The size of the tank depends on your desired run time during an outage. Natural gas units avoid this cost but require a sufficiently sized gas line connection.

Maintenance and Service Contracts

An industrial generator is a complex piece of machinery that requires regular maintenance to ensure reliability and longevity. This includes oil changes, filter replacements, battery checks, load bank testing, and general inspections. A preventative maintenance contract, while an ongoing expense, is a wise investment. I've found that proactive maintenance significantly reduces the likelihood of costly emergency repairs and extends the life of the unit. Factor these recurring costs into your long-term budget when reviewing any industrial generator set price quote.

Ancillary Equipment and Accessories

Several essential components might not be included in the base industrial generator set price quote but are critical for its operation or safety.

- Automatic Transfer Switch (ATS): Essential for standby generators, the ATS detects power outages and seamlessly transfers the electrical load to the generator.

- Block Heaters: Keep the engine warm in cold climates, ensuring reliable starting.

- Battery Chargers: Maintain the starting batteries at optimal charge.

- Remote Monitoring Systems: Allow you to monitor the generator's status and receive alerts from off-site.

- Fuel Polishing Systems: Important for diesel generators to prevent fuel degradation and contamination.

- Load Bank Testing: Periodically testing the generator at full load is crucial to ensure it performs as expected under real-world conditions. This is often a separate service.

Warranty and Support

A good warranty provides peace of mind and protection against manufacturing defects. Beyond the warranty, evaluate the supplier's after-sales support, including parts availability, technical assistance, and emergency service response times. A lower industrial generator set price quote might seem appealing, but if it comes with poor support, it could lead to significant operational headaches and expenses down the line.

Navigating the Market: How to Secure the Best Industrial Generator Set Price Quote

Securing the right industrial generator set price quote isn't just about finding the cheapest option; it's about finding the best value for your specific needs. It requires a strategic approach and clear communication with potential suppliers.

Define Your Needs Clearly

What's the single most critical piece of information you need before even asking for an industrial generator set price quote? It's a precise understanding of your power requirements. Conduct a professional load assessment to determine the peak load, continuous load, and any specific motor starting requirements. Also, consider the desired run time during an outage, the environmental conditions (temperature, altitude), and any specific regulatory compliance needs. The more detailed your specifications, the more accurate the quotes you'll receive.

Research Reputable Suppliers

Don't just go with the first company you find. Look for suppliers with a proven track record in industrial generator sales, installation, and service. Check their certifications, customer reviews, and ask for references. A reputable supplier won't just sell you a generator; they'll act as a partner, guiding you through the selection process and providing ongoing support. I've found that a strong relationship with your supplier is invaluable.

Request Detailed Quotes

When you request an industrial generator set price quote, insist on a detailed, itemized breakdown. This should clearly list the generator unit, ATS, fuel tank, installation labor, permits, freight, commissioning, and any other associated costs. This level of detail allows you to compare different commercial generator pricing factors from various vendors accurately and identify any hidden fees. Avoid vague or lump-sum quotes.

Consider Used or Refurbished Units

For certain applications, a used or refurbished industrial generator can offer significant cost savings. However, this path requires careful consideration. Ensure the unit comes from a reputable dealer who has thoroughly inspected, serviced, and ideally, load-tested the generator. Ask about its service history, run hours, and any remaining warranty. While the initial industrial generator set price quote might be lower, factor in potential higher maintenance costs or shorter lifespan.

Negotiate and Compare

Once you have multiple detailed industrial generator set price quotes, take the time to compare them thoroughly. Don't hesitate to negotiate. Sometimes, suppliers can offer better terms, bundle services, or adjust pricing, especially if they know you're evaluating other options. Look beyond just the bottom line; consider the total package, including warranty, service, and the supplier's reputation.

Making an Informed Decision on Your Industrial Generator Set Price Quote

Ultimately, securing an industrial generator set price quote is just the first step in a significant investment for your business. It's not merely about the cost of the equipment, but about the long-term reliability, efficiency, and peace of mind it provides. By understanding the various factors that influence the price, from power output and fuel type to installation complexities and ongoing maintenance, you empower yourself to make a truly informed decision.

Remember, a cheap industrial generator set price quote might end up being the most expensive in the long run if it doesn't meet your needs, incurs high operational costs, or lacks adequate support. Focus on value, reliability, and the total cost of ownership. Investing wisely in your power infrastructure is an investment in your business's continuity and future success.

For more detailed information, please visit our official website:industrial generator set price quote

About the author: Dr. Anya Sharma is a seasoned energy consultant with over 15 years of experience in industrial power solutions. Holding a Ph.D. in Electrical Engineering, she specializes in optimizing energy infrastructure for commercial and industrial clients. Her insights into generator procurement, installation, and long-term maintenance have saved countless businesses significant capital. Anya is passionate about sustainable and reliable power, helping organizations make informed decisions that ensure operational continuity.