Powering Progress: The Indispensable Role of a Custom Industrial Generator Set Manufacturer

In today's rapidly evolving industrial landscape, the demand for reliable, efficient, and highly specialized power solutions has never been greater. Off-the-shelf generator sets, while suitable for some standard applications, often fall short when faced with the unique challenges and stringent requirements of modern industrial operations. This is precisely where the expertise of a custom industrial generator set manufacturer becomes not just beneficial, but absolutely essential. Frankly speaking, the difference between a generic power source and a tailor-made solution can mean the difference between seamless operation and costly downtime.

Have you ever wondered why some industrial facilities seem to run flawlessly, even in the face of grid instability or peak demand, while others struggle? Often, the answer lies in their power infrastructure, specifically, the bespoke nature of their generator sets. A custom approach ensures that every aspect of the power solution is optimized for the specific environment, load profile, and operational goals of the client. It's about more than just generating electricity; it's about engineering a power ecosystem that integrates seamlessly with your existing systems and future aspirations.

The Imperative for Customization: Beyond Standard Solutions

The industrial sector is incredibly diverse, encompassing everything from data centers and manufacturing plants to mining operations, hospitals, and remote construction sites. Each of these environments presents a unique set of demands on power generation. A standard generator, designed for general use, simply cannot account for these specific variables. This is where the true value of a custom industrial generator set manufacturer shines through. They don't just sell you a product; they provide a meticulously engineered solution.

Consider, for instance, a data center that requires absolute uptime and precise voltage regulation, or a remote mining site operating in extreme temperatures with limited access to fuel. A standard generator might struggle with the continuous high load of a data center, leading to efficiency losses or even system failures. For the mining site, a generic unit might not withstand the harsh environmental conditions or be optimized for the specific fuel available, leading to frequent maintenance and operational disruptions. Interestingly enough, these scenarios highlight the critical need for power solutions that are not just robust, but also intelligently adapted.

Bespoke power solutions for industry address a multitude of factors that off-the-shelf models cannot. These include:

- Specific Power Output & Voltage Requirements: Industrial equipment often has very precise power needs that standard generators might not meet efficiently, leading to underpowering or overspending on oversized units.

- Environmental Conditions: Extreme temperatures (hot or cold), high humidity, dusty environments, or corrosive atmospheres demand specialized enclosures, cooling systems, and material choices.

- Fuel Type Flexibility: While diesel is common, some operations may require natural gas, propane, or even dual-fuel capabilities for cost efficiency or environmental compliance.

- Noise & Emission Regulations: Urban or residential proximity often necessitates advanced sound attenuation and emission control systems, which are typically optional or limited on standard models.

- Footprint & Space Constraints: Limited physical space might require a compact design, a vertical configuration, or even a containerized solution.

- Integration with Existing Systems: Seamless integration with building management systems (BMS), SCADA, or existing grid infrastructure requires custom control panels and communication protocols.

- Mobility & Portability: For construction or rental fleets, a custom design might focus on ease of transport, ruggedness, and rapid deployment features.

In my experience, trying to force a square peg into a round hole with power generation always leads to inefficiencies, higher operating costs, and increased risk. A custom solution, on the other hand, is built from the ground up to perfectly fit the unique contours of your operational needs.

The Anatomy of Customization: Key Design & Engineering Considerations

The process of creating a custom industrial generator set is a complex interplay of engineering expertise, client collaboration, and meticulous attention to detail. It begins long before any metal is cut or wires are connected, with a deep dive into the client's specific requirements. A leading custom industrial generator set manufacturer will employ a team of highly skilled engineers who specialize in mechanical, electrical, and control systems design.

Power Output and Load Profile Analysis

The first and arguably most critical step is to accurately assess the required power output and understand the load profile. This isn't just about peak demand; it's about understanding continuous loads, transient loads, reactive power needs, and future expansion plans. Many experts agree that overestimating leads to unnecessary capital expenditure and inefficient operation, while underestimating leads to system instability and potential failure. Sophisticated load bank testing and power quality analysis are often part of this initial phase.

Engine and Alternator Selection

The core of any generator set is its engine and alternator. For custom solutions, the manufacturer will select these components based on the specific power requirements, fuel type, desired longevity, and maintenance intervals. Options range from robust diesel engines known for their reliability and fuel efficiency to natural gas engines preferred for lower emissions and continuous operation where gas lines are available. The alternator must be precisely matched to the engine and the electrical load, considering factors like voltage regulation, harmonic distortion, and fault current capacity.

Cooling Systems Optimization

Effective cooling is paramount for generator longevity and performance, especially in high-temperature environments or continuous operation. Custom solutions can incorporate oversized radiators, remote radiators, heat exchangers for liquid-cooled systems, or specialized airflows for optimal heat dissipation. For extreme conditions, even custom fan designs or specific coolant types might be employed.

Enclosures and Sound Attenuation

Noise pollution and environmental protection are significant concerns. A custom industrial generator set manufacturer can design enclosures that are not only weatherproof and secure but also highly effective at reducing noise levels to meet strict local regulations. This often involves advanced acoustic materials, specialized baffling, and exhaust silencers. Beyond noise, enclosures can be designed for specific security levels, fire suppression, or even explosion-proof requirements for hazardous environments.

Advanced Control Systems and Paralleling

Modern industrial operations demand sophisticated control. Custom generator sets feature advanced digital control panels that offer comprehensive monitoring, remote access, automated start/stop functionality, and fault diagnostics. For applications requiring multiple generators, paralleling switchgear is designed to allow units to operate in sync, sharing the load efficiently, providing redundancy, and enabling maintenance without full system shutdown. This level of control is crucial for mission-critical applications.

The Manufacturing Journey: From Blueprint to Commissioning

Once the design phase is complete and all specifications are finalized, the custom industrial generator set manufacturer moves into the manufacturing and assembly phase. This is where the theoretical design takes physical form, a process that demands precision, quality control, and adherence to the highest engineering standards.

Component Sourcing and Quality Assurance

A reputable manufacturer sources components from trusted global suppliers, ensuring that every part, from the engine block to the smallest sensor, meets stringent quality benchmarks. This includes rigorous inspection of incoming materials and components to prevent defects from entering the assembly line. I've found that the best manufacturers are transparent about their supply chain and component origins.

Precision Assembly and Fabrication

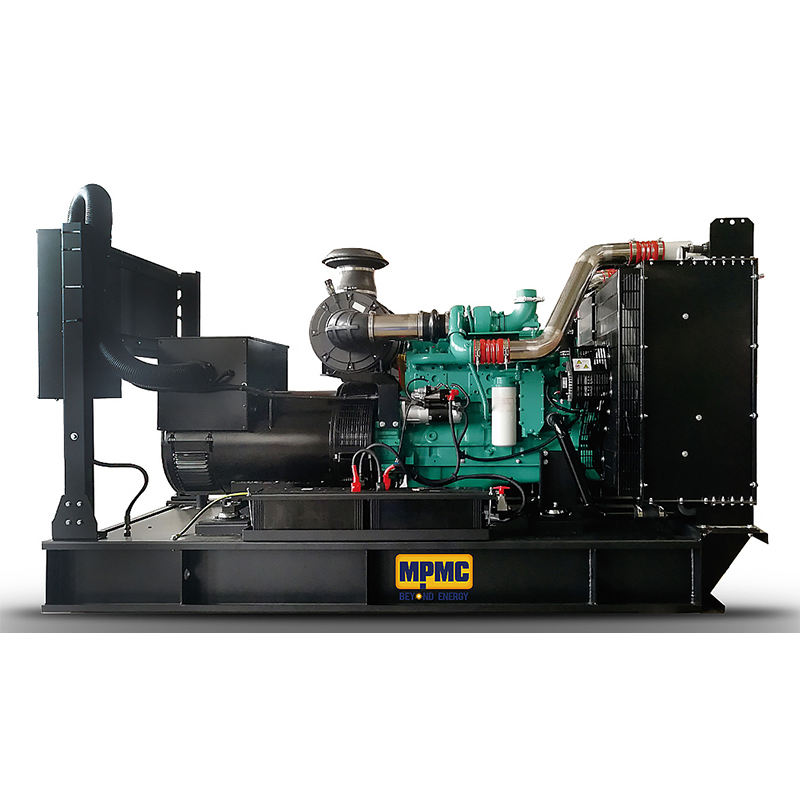

The assembly process is highly specialized. Skilled technicians meticulously integrate the engine, alternator, cooling system, fuel system, exhaust, and control panel onto a robust base frame. Custom fabrication often involves welding, machining, and painting of enclosures, fuel tanks, and structural components to exact specifications. Every connection, every weld, and every wire run is executed with precision, often following detailed CAD drawings and schematics.

Rigorous Testing and Validation

This is perhaps the most critical stage before deployment. Every custom generator set undergoes comprehensive factory acceptance testing (FAT) to validate its performance against the agreed-upon specifications. This includes:

- Load Bank Testing: Running the generator at various load levels (0%, 25%, 50%, 75%, 100%, and sometimes even overload) to verify its power output, voltage regulation, frequency stability, and fuel consumption.

- Transient Response Testing: Assessing how quickly the generator responds to sudden changes in load.

- Safety System Checks: Verifying the functionality of all safety shutdowns for low oil pressure, high coolant temperature, overspeed, etc.

- Noise and Emission Testing: Measuring sound levels and exhaust emissions to ensure compliance with regulatory standards.

- Control System Validation: Testing all control panel functions, remote monitoring capabilities, and alarm systems.

To be honest, skipping or rushing this phase is a huge risk. Proper testing ensures that when the generator arrives on-site, it performs exactly as expected, minimizing commissioning time and avoiding costly surprises.

Installation and Commissioning Support

While the manufacturer may not always perform the final on-site installation, they typically provide detailed installation guidelines and often offer commissioning services or supervision. This ensures that the generator is correctly integrated into the client's infrastructure, all connections are secure, and the system is calibrated for optimal performance in its operational environment. This post-delivery support is a hallmark of reliable custom generator suppliers.

Choosing the Right Custom Industrial Generator Set Manufacturer

Selecting the right partner for your industrial power needs is a decision that will impact your operations for years to come. It’s not just about finding someone who can build a generator; it’s about finding a strategic partner who understands your business and can deliver a solution that truly adds value. Here are key factors to consider:

Experience and Expertise

Look for a manufacturer with a proven track record in designing and building custom industrial generator sets for applications similar to yours. Their experience in navigating complex regulations, diverse environmental conditions, and specific industry demands is invaluable. Ask for case studies or references.

Engineering Capabilities

Assess their in-house engineering team. Do they have specialists in mechanical, electrical, and control systems? Do they utilize advanced design software (CAD, FEA)? A strong engineering department is the backbone of truly bespoke solutions.

Manufacturing Facilities and Quality Control

Visit their facilities if possible, or request virtual tours and detailed descriptions of their manufacturing processes. Look for evidence of robust quality control procedures at every stage, from component sourcing to final testing. Certifications like ISO 9001 are good indicators of commitment to quality.

After-Sales Support and Service Network

A generator set is a long-term investment. What kind of warranty do they offer? Do they provide comprehensive after-sales support, including spare parts availability, preventative maintenance programs, and emergency repair services? A strong service network ensures peace of mind and minimizes downtime.

Customization Flexibility

How willing and capable are they to adapt to unique requirements? Some manufacturers offer "customization" that is merely a selection from a limited set of options. A true custom industrial generator set manufacturer will engage in a deep consultative process, offering innovative solutions to complex problems.

Compliance and Certifications

Ensure they comply with all relevant industry standards, safety regulations, and environmental certifications (e.g., EPA, CARB, CE). This is crucial for both operational safety and regulatory adherence.

In my experience, a transparent and communicative manufacturer who prioritizes understanding your specific needs will always deliver a superior product and a better overall experience. Don't hesitate to ask detailed questions and challenge their proposals to ensure they've truly grasped your requirements.

The Future of Industrial Power: Innovation and Sustainability

The landscape of industrial power generation is constantly evolving, driven by advancements in technology, increasing environmental awareness, and the push for greater efficiency. A forward-thinking custom industrial generator set manufacturer isn't just building for today's needs; they're innovating for tomorrow's challenges.

Integration with Renewable Energy

Hybrid power solutions, combining generators with solar, wind, or battery storage, are becoming more prevalent. Custom manufacturers are at the forefront of designing generator sets that can seamlessly integrate with these renewable sources, optimizing fuel consumption and reducing carbon footprints. This involves sophisticated control systems that intelligently manage power flow between different sources.

Advanced Monitoring and Predictive Maintenance

The rise of IoT (Internet of Things) and AI (Artificial Intelligence) is transforming generator maintenance. Custom units can be equipped with advanced sensors and connectivity that allow for real-time remote monitoring, predictive maintenance analytics, and even self-diagnosis. This proactive approach minimizes unexpected breakdowns and extends the lifespan of the equipment.

Sustainable Fuel Options

Beyond traditional diesel and natural gas, manufacturers are exploring and implementing solutions for alternative fuels like hydrogen, biogas, and even synthetic fuels. As industries strive for carbon neutrality, the ability to design generators compatible with these cleaner fuels will be a significant differentiator.

Modular and Scalable Designs

For businesses with uncertain future power needs, modular generator designs allow for easy expansion or reconfiguration. This flexibility ensures that the initial investment remains relevant as operational demands change, offering a truly future-proof power solution.

Frankly speaking, the role of a custom industrial generator set manufacturer is more vital than ever. They are not just suppliers of equipment; they are architects of critical infrastructure, enabling industries to operate reliably, efficiently, and sustainably. Investing in a custom-engineered power solution is an investment in the resilience and future success of your operations.

For more detailed information, please visit our official website:custom industrial generator set manufacturer

About the author: Dr. Evelyn Reed is a seasoned expert in industrial power systems, with over 20 years of experience in engineering and project management for large-scale energy infrastructure. Specializing in bespoke generator solutions and sustainable power integration, she has advised numerous global enterprises on optimizing their energy resilience and efficiency. Her insights are drawn from extensive hands-on experience and a deep understanding of cutting-edge power generation technologies.