Mastering Resilience: Mitigating Factory Downtime Due to Power Failure

In the relentless rhythm of modern manufacturing, every second counts. Production lines hum, machinery whirs, and goods move seamlessly from raw material to finished product. But what happens when that rhythm is abruptly broken? What happens when the lights go out, and the power grid falters? Frankly speaking, for a factory, a power failure isn't just an inconvenience; it's a catastrophic event that can ripple through supply chains, erode profits, and tarnish reputations. The core challenge, then, lies in effectively mitigating factory downtime due to power failure. It’s about building resilience, not just reacting to crises.

To be honest, many factory managers and business owners often underestimate the true cost of an outage until they're staring down the barrel of significant losses. It's not just about the lost production during the blackout; it's about the time it takes to safely shut down equipment, the potential damage to machinery, the wasted raw materials, and the arduous process of restarting complex systems. In my experience, a proactive approach isn't just beneficial; it's absolutely essential for survival in today's competitive landscape. This article will delve deep into practical strategies, technological advancements, and operational best practices to help your facility weather any power storm.

The Unseen Costs: Why Power Outages Cripple Production

When a power outage hits a manufacturing facility, the immediate thought is often about the halt in production. While that's undoubtedly the most visible impact, the true cost extends far beyond the idle machinery. Interestingly enough, the ripple effect of a power failure can be far more damaging and long-lasting than many initially perceive. Have you ever truly calculated the ripple effect of even a short power interruption on your factory's bottom line?

Beyond the Obvious: Financial Repercussions

The financial fallout from factory downtime due to power failure is multifaceted. Firstly, there's the direct loss of revenue from unproduced goods. If your line stops for an hour, that's an hour of lost output that can rarely be fully recovered. Then there are the costs associated with spoiled materials, especially in industries like food processing, pharmaceuticals, or chemical manufacturing where temperature or process stability is critical. Imagine a batch of temperature-sensitive chemicals becoming unusable, or a freezer full of perishable goods thawing out. These are not minor losses; they can amount to hundreds of thousands, if not millions, of dollars.

Beyond that, consider the labor costs. Employees are still on the clock, but they're not producing. This idle time is a direct drain on resources. There are also potential penalties for missed deadlines or contractual obligations, which can damage client relationships and lead to a loss of future business. Many experts agree that the reputational damage, while harder to quantify, can be one of the most insidious costs. A reputation for unreliability can send customers looking for more stable suppliers.

Safety and Compliance Challenges

It's worth noting that power outages also introduce significant safety risks. Sudden shutdowns can leave equipment in dangerous states, potentially trapping materials, leaving machinery in mid-cycle, or disabling critical safety interlocks. Restarting operations after a blackout can be equally hazardous, requiring meticulous procedures to ensure all systems are brought back online safely and in the correct sequence. Furthermore, depending on the industry, there might be regulatory compliance issues related to process stability, waste management, or environmental controls that are compromised during an outage, leading to fines or legal repercussions.

Proactive Strategies: Fortifying Your Factory Against Power Failure

The best defense against factory downtime due to power failure is a strong offense. Proactive measures are the cornerstone of a resilient manufacturing operation. It's about anticipating potential problems and having robust solutions in place long before the lights flicker.

Robust Power Infrastructure Assessment

The first step in mitigating factory downtime due to power failure is a thorough assessment of your existing power infrastructure. This isn't just about checking if the lights work; it involves a detailed audit of your main power feed, transformers, switchgear, distribution panels, and internal wiring. Identify single points of failure – areas where a single component failure could bring down a significant portion of your operations. Are your transformers aging? Is your switchgear overloaded? Are there any sections of your plant relying on a single, vulnerable power line? Upgrading aging infrastructure and diversifying power paths where possible can significantly reduce risk.

Implementing Uninterruptible Power Supplies (UPS)

For critical control systems, data servers, and sensitive equipment, an Uninterruptible Power Supply (UPS) is non-negotiable. A UPS provides immediate, albeit temporary, power when the main supply fails, allowing for a graceful shutdown of systems or bridging the gap until backup generators kick in. There are different types of UPS systems – online, line-interactive, and standby – each offering varying levels of protection and cost. Sizing a UPS correctly is crucial; it needs to provide enough power for long enough to either safely shut down equipment or allow generators to take over. I've found that investing in high-quality, properly sized UPS systems pays dividends by preventing data corruption, equipment damage, and chaotic shutdowns.

Backup Generator Systems: Your First Line of Defense

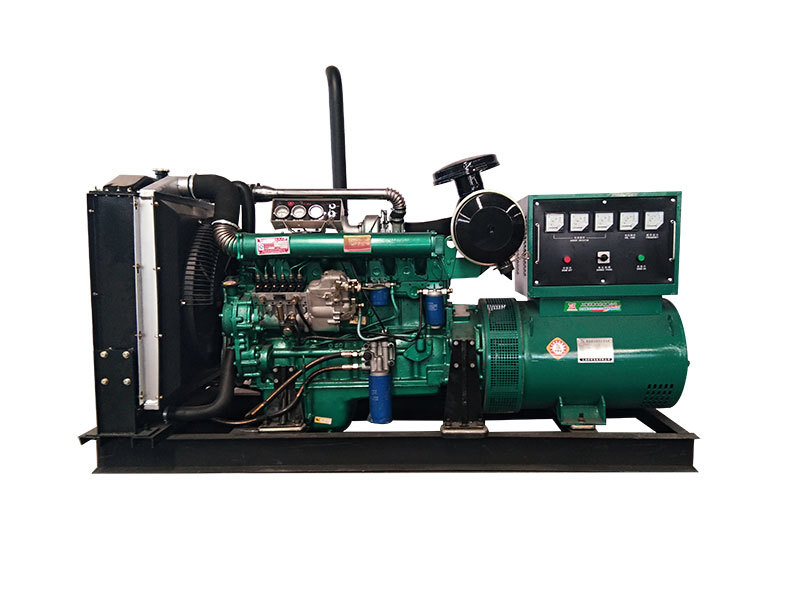

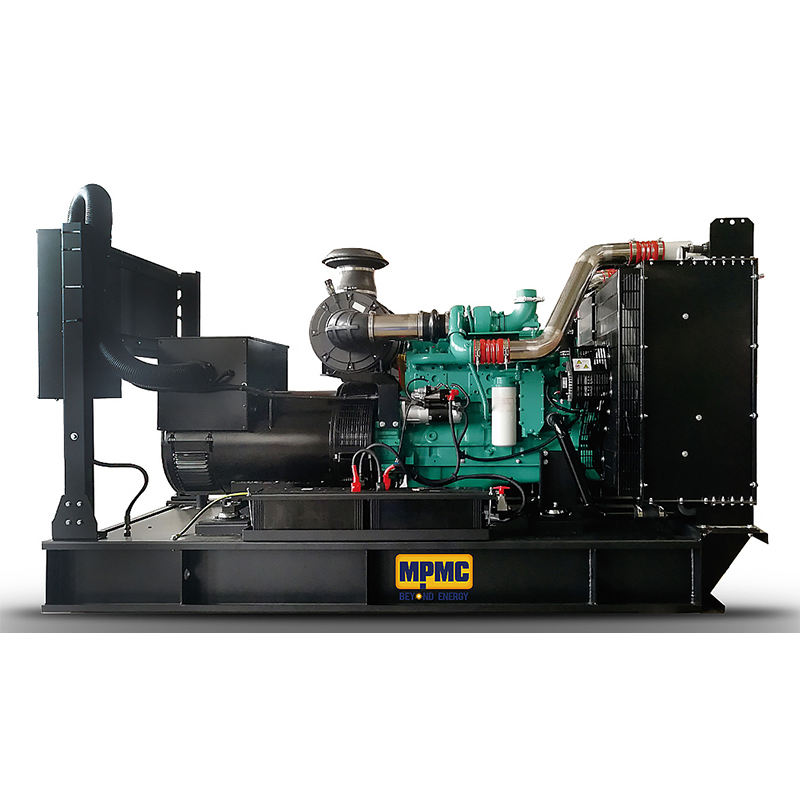

For sustained power during an outage, backup generator systems are the workhorses. These can range from large diesel generators capable of powering an entire factory to smaller natural gas units for specific critical loads. The key is not just having a generator, but ensuring it's properly maintained and equipped with an Automatic Transfer Switch (ATS). An ATS detects a power failure and automatically switches the factory's load to the generator, then seamlessly switches back to grid power when it's restored. Regular testing – under load – is paramount. Many experts agree that a generator that hasn't been tested regularly is little more than a very expensive paperweight when you truly need it.

Technological Solutions: Smart Systems for Seamless Operations

Beyond traditional backup power, modern technology offers sophisticated solutions for enhancing power reliability and minimizing the impact of outages. These innovations are transforming how factories approach mitigating factory downtime due to power failure, moving towards more intelligent and autonomous systems.

Advanced Power Monitoring and Management Systems

The advent of IoT (Internet of Things) and advanced sensor technology has revolutionized power management. Implementing a comprehensive power monitoring system, often integrated with SCADA (Supervisory Control and Data Acquisition) or MES (Manufacturing Execution System) platforms, allows real-time visibility into your factory's power consumption and quality. These systems can detect anomalies, voltage fluctuations, or potential equipment failures before they lead to an outage. Predictive analytics, powered by AI, can even forecast potential issues based on historical data, enabling proactive maintenance and preventing production losses from outages. This level of insight is invaluable for maintaining consistent power quality and identifying vulnerabilities.

Energy Storage Solutions: Batteries and Beyond

Large-scale battery energy storage systems (BESS), primarily lithium-ion but also emerging technologies like flow batteries, are becoming increasingly viable for industrial applications. These systems can serve multiple purposes: providing short-duration backup power, smoothing out power fluctuations, and even participating in demand response programs to reduce electricity costs. For factories, a BESS can bridge the gap between grid failure and generator startup, or even provide sustained power for critical processes for several hours. They offer a cleaner, quieter alternative to generators for certain applications and can be integrated with renewable energy sources.

Microgrids and Decentralized Power

For ultimate resilience, some factories are exploring microgrids. A microgrid is a localized energy grid that can disconnect from the traditional grid and operate autonomously. This means if the main utility grid goes down, your factory's microgrid can "island" itself and continue operating using its own generation sources (e.g., solar panels, wind turbines, combined heat and power plants, and battery storage). This provides unparalleled industrial power reliability solutions, making your factory virtually immune to regional grid failures. While a significant investment, the long-term benefits in terms of operational continuity and energy independence are substantial.

Developing a Comprehensive Downtime Mitigation Plan

Having the right equipment is only half the battle. A well-thought-out, comprehensive plan is crucial for effectively mitigating factory downtime due to power failure. This plan should cover everything from emergency response to long-term maintenance strategies.

Emergency Response Protocols and Training

Every factory needs a clear, documented emergency response protocol for power failures. This includes detailed procedures for safe shutdown of equipment, communication channels for informing staff and stakeholders, and designated roles and responsibilities during an outage. More importantly, this plan needs to be regularly communicated and practiced through drills. Employees should know exactly what to do when the power goes out, from securing their workstations to activating backup systems. Training should cover not just the technical aspects but also safety procedures during a blackout.

Redundancy and Diversification

Where feasible and economically viable, building redundancy into your power supply and critical equipment is a powerful strategy. This could mean having dual power feeds from different substations, ensuring that if one fails, the other can take over. It also applies to critical machinery; having backup pumps, compressors, or control units can prevent a single point of failure from halting your entire operation. For highly critical processes, geographically dispersed operations or distributed manufacturing can provide an ultimate layer of resilience, though this is a more complex undertaking.

Regular Maintenance and Testing Regimes

The most sophisticated backup power systems are useless if they don't work when needed. A robust preventative maintenance schedule for all power infrastructure, including UPS units, generators, ATS, and even main switchgear, is absolutely critical. This goes beyond routine checks; it involves load testing generators, checking battery health in UPS systems, and inspecting electrical connections for wear and tear. Many experts agree that investing in a predictive maintenance program, using sensors and data analytics to anticipate failures, can significantly reduce unexpected downtime. This proactive approach is key to preventing production losses from outages.

The Human Element: Training and Culture for Resilience

While technology and robust infrastructure are vital, the human element plays an indispensable role in mitigating factory downtime due to power failure. A well-trained, empowered workforce operating within a proactive culture can make all the difference when an unexpected outage occurs. What's the true cost of an untrained team when a critical system fails?

Empowering Your Workforce

Investing in comprehensive training for your operational and maintenance staff is paramount. This training should cover not only the theoretical understanding of your power systems but also practical, hands-on experience with emergency shutdown procedures, generator startup, UPS monitoring, and troubleshooting common issues. Empowering employees with the knowledge and confidence to react swiftly and correctly during a power failure can significantly reduce the duration and impact of downtime. Regular refreshers and scenario-based training can keep skills sharp and ensure everyone knows their role.

Fostering a Proactive Maintenance Culture

Beyond specific training, cultivating a culture of proactive maintenance and vigilance is crucial. This means encouraging employees to report even minor anomalies, fostering a sense of ownership over equipment, and promoting continuous improvement in power reliability strategies. When every team member understands the importance of preventing downtime and is equipped to contribute, your factory becomes inherently more resilient. It's about shifting from a reactive "fix-it-when-it-breaks" mentality to a predictive "prevent-it-from-breaking" approach.

In conclusion, mitigating factory downtime due to power failure is a complex but achievable goal. It requires a multi-faceted approach that combines robust infrastructure, cutting-edge technology, meticulous planning, and a highly trained workforce. By investing in resilient power solutions like emergency power systems for manufacturing, implementing smart monitoring systems, and fostering a proactive culture, factories can significantly reduce their vulnerability to outages, ensuring continuous operation and protecting their bottom line. The future of manufacturing resilience lies in embracing these comprehensive strategies, transforming potential crises into mere blips on the radar.

For more detailed information, please visit our official website:factory downtime mitigation

About the author: Dr. Evelyn Reed is a leading expert in industrial power systems and operational resilience. With over two decades of experience in manufacturing engineering and facility management, she specializes in designing and implementing robust strategies for mitigating factory downtime. Her work focuses on integrating advanced technologies and best practices to ensure continuous production and energy efficiency for complex industrial operations.