Powering Progress: The Essential Role of a Leading Diesel Generator Manufacturer

In today's interconnected world, reliable power isn't just a convenience; it's a fundamental necessity. From hospitals and data centers to construction sites and remote mining operations, an uninterrupted power supply is crucial for safety, productivity, and profitability. This is precisely where a dedicated diesel generator manufacturer steps in, serving as the backbone of countless operations worldwide. To be honest, without their expertise, many critical infrastructures would simply grind to a halt during outages or in off-grid scenarios.

Have you ever wondered about the intricate process behind creating these robust machines that keep our world running? It's far more complex than just assembling an engine and an alternator. It involves precision engineering, rigorous testing, and a deep understanding of diverse power requirements. This article will delve into the world of diesel generators, exploring what defines a leading manufacturer, the intricacies of their production, and how to choose the right partner for your power needs.

The Unseen Architects of Power: What Defines a Top-Tier Diesel Generator Manufacturer?

When we talk about a top-tier diesel generator manufacturer, we're not just discussing a company that builds machines. We're talking about innovators, problem-solvers, and partners in ensuring continuous operation. What truly sets them apart from the competition? In my experience, it boils down to several key pillars:

Innovation and Engineering Excellence

A leading manufacturer is constantly pushing the boundaries of technology. This isn't just about making generators more powerful; it's about making them more fuel-efficient, quieter, more environmentally friendly, and easier to maintain. They invest heavily in research and development, exploring advanced control systems, remote monitoring capabilities, and integrating smart technologies. Frankly speaking, the best manufacturers anticipate future needs, developing solutions that are not only robust today but also adaptable for tomorrow's challenges. They understand that while the core principle of a diesel engine remains, the surrounding technology evolves rapidly.

Unwavering Commitment to Quality

Quality isn't just a buzzword for a reputable diesel generator manufacturer; it's their guiding principle. This means sourcing only the highest-grade components, often from globally recognized suppliers for engines, alternators, and control panels. Every step of the manufacturing process, from welding the frame to wiring the control panel, undergoes stringent quality control checks. The final product isn't just assembled; it's meticulously crafted and tested under various load conditions to ensure it performs flawlessly when it matters most. Many experts agree that a manufacturer's commitment to quality is directly reflected in the longevity and reliability of their generators.

Customization and Flexibility in Industrial Diesel Generator Solutions

One size rarely fits all in the world of power generation. A superior manufacturer understands this and offers extensive customization options. Whether it's for a specific industrial application requiring unique voltage outputs, a sound-attenuated enclosure for urban environments, or a mobile unit for rapid deployment, they can tailor their offerings. This flexibility in providing industrial diesel generator solutions is crucial for clients with specific and often complex requirements. They don't just sell products; they provide solutions designed to meet precise operational demands.

The Journey of Power: Inside the Manufacturing Process

Understanding the journey a diesel generator takes from raw materials to a fully operational unit provides valuable insight into the expertise of its manufacturer. It's a multi-stage process that demands precision, coordination, and specialized skills.

Design and Engineering

The process begins long before any metal is cut. Highly skilled engineers use advanced CAD software to design the generator set, ensuring optimal performance, thermal management, and structural integrity. This phase involves selecting the right engine, alternator, and control system components that will work in perfect harmony. They also consider factors like fuel efficiency, emissions standards, and ease of maintenance. This initial design dictates the entire production path, so it's a critical stage where expertise truly shines.

Component Sourcing and Fabrication

Once the design is finalized, the manufacturer sources high-quality components. This includes the diesel engine (often from renowned brands), the alternator (which converts mechanical energy into electrical energy), the robust base frame, fuel tanks, cooling systems, and advanced control panels. Many parts, like the enclosure and exhaust system, are fabricated in-house or by trusted partners, ensuring they meet the exact specifications and quality standards. It's worth noting that the choice of component suppliers reflects directly on the reliability of the final product.

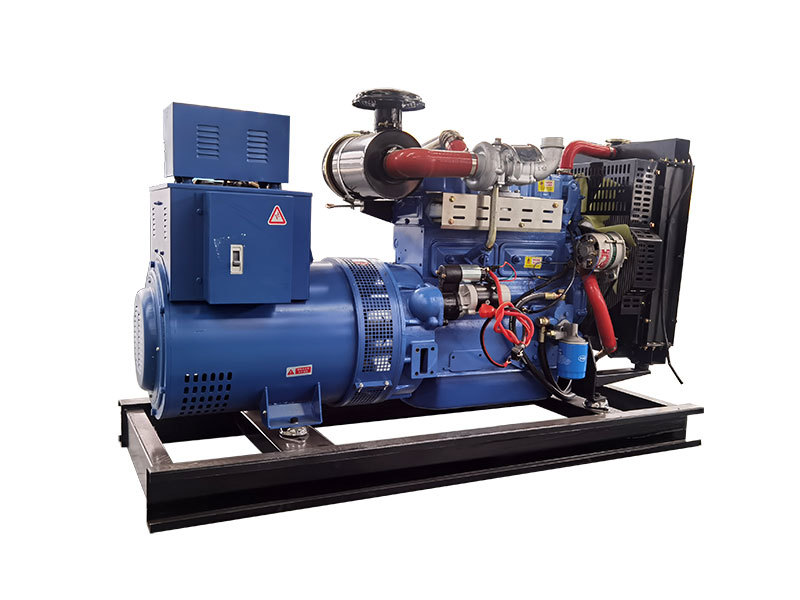

Assembly and Integration

This is where the magic happens. Skilled technicians meticulously assemble the various components onto the base frame. The engine is mounted, the alternator is coupled, and the cooling system, fuel lines, and exhaust system are integrated. The electrical wiring, connecting the alternator to the control panel and output terminals, is a particularly delicate and crucial step, requiring absolute precision to ensure safety and functionality. Every connection is checked and re-checked.

Rigorous Testing and Quality Assurance

Perhaps the most critical phase is testing. A reputable diesel generator manufacturer subjects every single unit to a battery of tests before it leaves the factory. This includes:

- Load Bank Testing: Running the generator at various load percentages (25%, 50%, 75%, 100%, and sometimes even overload) to ensure stable voltage, frequency, and temperature performance.

- Safety Checks: Verifying all safety shutdowns and alarms function correctly.

- Sound Level Testing: For enclosed units, measuring noise levels to ensure compliance with specifications.

- Vibration Analysis: Ensuring smooth operation and minimal vibration.

Choosing Your Power Partner: Key Considerations for Selecting a Diesel Generator Manufacturer

Selecting the right diesel generator manufacturer is a significant decision that impacts your operational continuity and long-term investment. It's not just about finding the cheapest option; it's about finding the best value and the most reliable partner. Here are some critical factors to consider:

Reputation and Experience

Look for manufacturers with a proven track record and extensive experience in the industry. How long have they been in business? Do they have a strong portfolio of successful installations in similar applications to yours? A long-standing reputation often indicates consistent quality and customer satisfaction. I've found that companies with decades of experience tend to have a deeper understanding of the nuances of power generation.

Product Range and Customization Capabilities

Does the manufacturer offer a diverse range of generators to meet various power requirements, from small residential backup units to large-scale industrial power solutions? More importantly, can they provide custom solutions if your needs are unique? This flexibility is a hallmark of a customer-centric manufacturer.

After-Sales Support and Service

A generator is a long-term investment. What kind of after-sales support does the manufacturer offer? This includes warranty, availability of spare parts, technical support, and maintenance services. A strong service network ensures that your generator remains operational throughout its lifespan, minimizing downtime. Interestingly enough, some manufacturers even offer remote monitoring services, allowing them to proactively identify and address potential issues.

Compliance and Certifications

Ensure the manufacturer complies with relevant international and local standards for quality, safety, and emissions (e.g., ISO certifications, CE marking, EPA compliance). These certifications are independent validations of their commitment to quality and responsible manufacturing practices.

Environmental Considerations

With increasing environmental awareness, consider manufacturers who are investing in cleaner engine technologies, reduced emissions, and more fuel-efficient designs. While diesel generators have their place, responsible manufacturing includes efforts to minimize their environmental footprint.

Applications and Industries: Where Diesel Generators Shine

The versatility and reliability of diesel generators make them indispensable across a vast array of sectors. A skilled diesel generator manufacturer serves a diverse clientele, understanding the unique power demands of each industry.

Critical Infrastructure

Hospitals, data centers, telecommunication hubs, and emergency services rely heavily on diesel generators for backup power. In these environments, even a momentary power disruption can have catastrophic consequences, making reliable backup power non-negotiable.

Industrial and Manufacturing

Factories, processing plants, and large-scale manufacturing facilities often require continuous power to avoid costly production halts. Diesel generators can provide primary power in remote locations or serve as robust backup for grid power.

Construction and Mining

On remote construction sites or in mining operations, where grid power is often unavailable or unreliable, mobile diesel generators are the primary source of electricity for machinery, lighting, and temporary facilities.

Commercial and Retail

Shopping malls, large retail stores, hotels, and office buildings use generators to maintain operations during outages, ensuring customer comfort and business continuity.

Agriculture and Remote Areas

Farms, agricultural processing units, and remote communities often depend on diesel generators for consistent power, especially where grid infrastructure is underdeveloped or non-existent.

The Future Landscape: Adaptability of the Diesel Generator Manufacturer

While renewable energy sources are gaining traction, the demand for diesel generators, particularly for backup and prime power in specific applications, remains strong. The future for a forward-thinking diesel generator manufacturer lies in adaptability and embracing evolving technologies.

Hybrid Solutions

Many manufacturers are exploring and implementing hybrid power solutions, combining diesel generators with renewable sources like solar panels and battery storage. This allows for optimized fuel consumption, reduced emissions, and enhanced reliability. The diesel generator acts as a reliable backup or supplements power during peak demand or when renewables are insufficient.

Advanced Controls and IoT

The integration of advanced control systems, remote monitoring, and IoT (Internet of Things) capabilities is becoming standard. This allows for predictive maintenance, real-time performance tracking, and remote diagnostics, significantly improving efficiency and reducing operational costs.

Cleaner Emissions and Fuel Efficiency

Ongoing research focuses on developing more fuel-efficient engines and technologies that reduce emissions, meeting increasingly stringent environmental regulations. This includes optimizing combustion processes and exploring alternative fuels or blends.

In conclusion, the role of a diesel generator manufacturer is pivotal in ensuring that the world continues to function smoothly, even when the grid falters. They are not just suppliers of equipment but providers of critical power solutions, constantly innovating to meet the complex and evolving demands of various industries. Choosing the right manufacturer means investing in reliability, quality, and peace of mind for your power needs.

For more detailed information, please visit our official website:Diesel generator manufacturer

About the author: Johnathan Power is a seasoned expert in industrial power generation, with over 20 years of experience in designing, manufacturing, and deploying robust energy solutions. His insights are drawn from extensive work with leading power system providers and a deep understanding of critical infrastructure requirements. Johnathan is passionate about reliable power and the innovations driving the industry forward.