Powering Progress: A Deep Dive into the World of Generator Manufacturers

Have you ever wondered what goes into powering our modern world, especially when the grid falters or when reliable electricity is simply unavailable? Frankly speaking, the answer often lies with the unsung heroes of energy independence: generator manufacturers. These companies are the backbone of countless industries, essential services, and even our homes, providing the critical power solutions that keep everything running smoothly.

To be honest, the scope of what generator manufacturers do is truly vast. They don't just assemble engines and alternators; they engineer sophisticated power systems designed for diverse applications, from massive industrial complexes and data centers to essential hospital facilities and residential backup power. Their work is a blend of cutting-edge technology, rigorous testing, and an unwavering commitment to reliability. In my experience, understanding their role is key to appreciating the complex infrastructure that supports our daily lives.

The Crucial Role of Generator Manufacturers in a Power-Dependent World

In today's interconnected world, an uninterrupted power supply isn't a luxury; it's a fundamental necessity. This is precisely where generator manufacturers step in, offering solutions that range from emergency standby power to continuous prime power for off-grid operations. Their products ensure that businesses don't face costly downtime, critical services like hospitals can continue saving lives, and homes remain comfortable and functional during outages. It's worth noting that their impact spans virtually every sector of the global economy.

The innovation driven by these manufacturers is relentless. They are constantly pushing the boundaries of what's possible, developing more efficient, cleaner, and smarter generators. This includes advancements in fuel efficiency, emission reduction technologies, and the integration of smart controls for remote monitoring and predictive maintenance. Many experts agree that the future of power generation will heavily rely on the continuous evolution driven by these dedicated companies.

From Standby to Prime Power: Understanding Generator Types

One of the first things you learn when delving into the world of generators is the sheer variety available, each designed for a specific purpose. Generator manufacturers produce units categorized primarily by their application:

- Standby Generators: These are perhaps the most common type for emergency power. They automatically kick in when the main power supply fails, ensuring seamless transition for homes, businesses, and critical facilities. Think of them as your reliable safety net.

- Prime Power Generators: Used as the primary source of power in remote locations or where grid power is unavailable or unreliable. Construction sites, mining operations, and remote villages often depend entirely on these robust units.

- Continuous Power Generators: Designed to operate non-stop for extended periods, providing constant power to applications that require uninterrupted electricity, often seen in industrial settings or large-scale data centers.

Beyond application, generators are also classified by their fuel type: diesel, natural gas, propane, bi-fuel (combining two fuel types), and even emerging hydrogen or hybrid solutions. Each fuel type has its advantages in terms of cost, availability, emissions, and maintenance, and reputable industrial power generator suppliers offer a wide array to meet diverse client needs.

The Engineering Excellence Behind the Scenes

The journey from concept to a fully functional generator is a testament to engineering excellence. It involves meticulous research and development, precision manufacturing, and exhaustive testing. Generator manufacturers invest heavily in R&D to improve performance, reduce environmental impact, and enhance user experience. This includes designing more efficient engines, developing advanced control systems, and engineering robust enclosures that can withstand harsh environments.

Quality control is paramount. Every component, from the smallest sensor to the massive engine block, undergoes rigorous inspection. Once assembled, the entire generator unit is subjected to a battery of tests, including load testing, vibration analysis, and sound level checks, to ensure it meets stringent performance and safety standards. This commitment to quality is what separates the leading manufacturers from the rest, ensuring that when you need power, it's there, without fail.

Key Players in the Global Generator Market

The global market for power generation equipment is dominated by a handful of prominent generator manufacturers, alongside numerous specialized and regional players. These companies have built their reputations on decades of innovation, reliability, and comprehensive customer support. Interestingly enough, while some focus on massive industrial solutions, others excel in compact, efficient units for residential or small commercial use.

When considering a generator, the manufacturer's reputation is often as important as the specifications of the unit itself. A strong brand typically signifies a commitment to quality, a robust supply chain for parts, and excellent after-sales service – factors that are crucial for long-term satisfaction and operational reliability.

Leading Names and Their Specialties

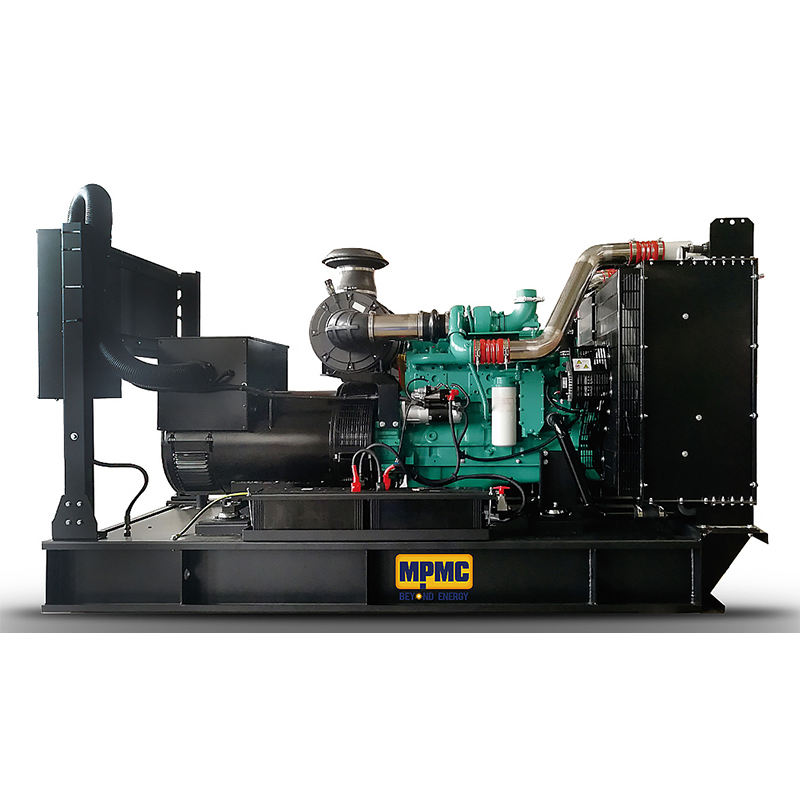

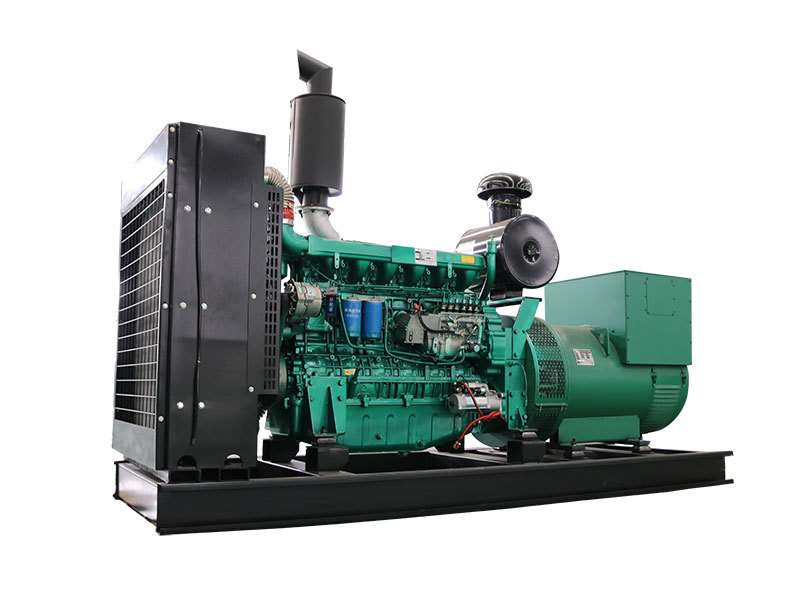

While it's impossible to list every significant player, certain names frequently come up in discussions about top generator manufacturers. Companies like Cummins, Caterpillar, Generac, and Kohler are often cited for their broad product lines and global reach. Cummins, for instance, is renowned for its powerful diesel and natural gas generators, serving everything from data centers to hospitals. Caterpillar, a giant in heavy machinery, produces incredibly robust generators for industrial and commercial applications, often integrated into larger power systems.

On the residential side, companies like Generac have become synonymous with home backup power, offering user-friendly and reliable solutions that automatically protect homes during outages. Similarly, Kohler offers a wide range of generators for both residential and commercial use, known for their durability and performance. Many of these leading home backup generator companies also provide comprehensive installation and maintenance services, making the process seamless for homeowners.

The Importance of After-Sales Service and Support

A generator is a significant investment, and its long-term performance hinges not just on its initial quality but also on the support available throughout its lifespan. This is where the commitment of generator manufacturers to after-sales service becomes critical. Reputable manufacturers offer extensive warranties, readily available spare parts, and a network of certified technicians for maintenance and repairs. I've found that a manufacturer's dedication to support can significantly reduce downtime and extend the life of your generator, making it a truly valuable asset.

This includes everything from routine preventative maintenance schedules to emergency repair services. A manufacturer that stands behind its product with a strong service network provides peace of mind, knowing that expert help is just a call away if an issue arises. This holistic approach to customer satisfaction is a hallmark of the best in the business.

The Manufacturing Process: From Raw Material to Reliable Power

The creation of a power generator is a complex symphony of engineering, material science, and precision assembly. It's far more than just bolting parts together; it's about integrating highly specialized components into a cohesive, reliable system. The diesel generator manufacturing process, for example, involves several intricate stages, each crucial to the final product's performance and longevity.

Frankly speaking, the journey begins long before assembly, with meticulous design and component sourcing. Every part, from the engine block to the smallest wire, is selected to meet specific performance criteria and durability standards. This attention to detail at every step is what ensures the generator will perform flawlessly when called upon.

Component Sourcing and Integration

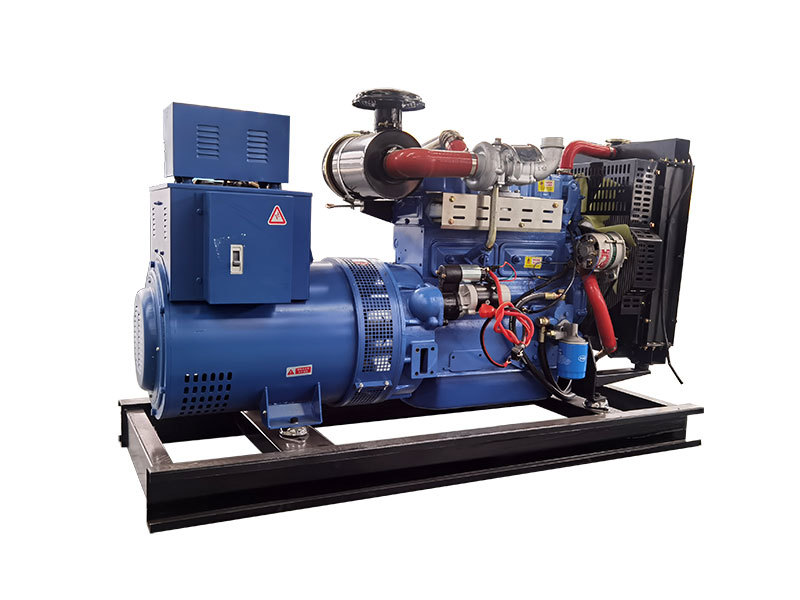

At the heart of every generator are two primary components: the engine and the alternator (also known as the generator end). Leading generator manufacturers often source these from specialized, world-renowned suppliers. For engines, you might find names like Perkins, John Deere, MTU, or even the manufacturer's own proprietary engines (e.g., Cummins engines in Cummins generators). These engines are engineered for specific fuel types and power outputs, designed for continuous, heavy-duty operation.

The alternator, responsible for converting mechanical energy into electrical energy, is equally critical. Companies like Stamford, Leroy-Somer, and Marathon Electric are prominent suppliers of high-quality alternators. Beyond these core components, a generator also includes a sophisticated control panel (the "brain" of the unit), a robust cooling system, a fuel system, and often a sound-attenuated enclosure. Integrating these diverse components seamlessly requires exceptional engineering and manufacturing expertise.

Rigorous Testing and Quality Control

Once assembled, a generator isn't immediately ready for shipment. It undergoes an exhaustive series of tests to ensure it meets all performance specifications, safety standards, and emission regulations. This is where the true quality of generator manufacturers shines through. Tests typically include:

- Load Testing: The generator is run at various loads (e.g., 25%, 50%, 75%, 100% of its rated capacity) for extended periods to verify its power output, voltage regulation, and stability under different demands.

- Transient Response Testing: This assesses how quickly and smoothly the generator responds to sudden changes in load, simulating real-world scenarios where appliances or machinery are switched on or off.

- Safety Checks: All safety features, such as automatic shutdowns for low oil pressure or high temperature, are verified.

- Noise and Vibration Testing: Especially important for residential or urban applications, these tests ensure the generator operates within acceptable noise and vibration limits.

- Emissions Testing: Generators must comply with strict environmental regulations, and manufacturers conduct thorough tests to ensure their units meet these standards.

This comprehensive testing phase ensures that every generator leaving the factory is a reliable, high-performance machine, ready to deliver power when it's needed most. It’s a critical step that many experts agree is non-negotiable for product integrity.

Innovations and Future Trends in Generator Manufacturing

The power generation landscape is constantly evolving, driven by technological advancements, environmental concerns, and changing energy demands. Generator manufacturers are at the forefront of this evolution, investing heavily in R&D to develop the next generation of power solutions. The focus is increasingly on sustainability, efficiency, and smart capabilities.

It's worth noting that simply building a powerful machine is no longer enough. The market demands generators that are not only reliable but also environmentally responsible and capable of integrating into complex, modern energy grids. This shift is leading to exciting innovations across the industry.

Embracing Green Technologies

Sustainability is a major driving force. Generator manufacturers are actively exploring and implementing greener technologies to reduce the environmental footprint of their products. This includes:

- Cleaner Burning Fuels: Development of generators optimized for natural gas or propane, which produce fewer emissions than diesel.

- Biofuel Compatibility: Designing engines that can run on various biofuels, offering a renewable alternative to traditional fossil fuels.

- Hybrid Systems: Integrating generators with renewable energy sources like solar panels or wind turbines, where the generator acts as a backup or supplements power during peak demand or low renewable output. This reduces overall fuel consumption and emissions.

- Advanced Emission Control Systems: Implementing sophisticated after-treatment systems, similar to those found in modern vehicles, to significantly reduce NOx, particulate matter, and other pollutants.

These efforts reflect a broader industry commitment to environmental stewardship, ensuring that reliable power doesn't come at an undue cost to the planet.

The Rise of Smart Generators and IoT

The Internet of Things (IoT) is revolutionizing how generators are monitored, managed, and maintained. Modern generators often come equipped with advanced control panels and connectivity features that allow for remote monitoring and diagnostics. This means owners can check their generator's status, fuel levels, and performance from anywhere in the world via a smartphone app or web portal. This capability is a game-changer, particularly for remote sites or large fleets of generators.

Beyond simple monitoring, smart generators leverage data analytics for predictive maintenance. By analyzing operational data, the system can identify potential issues before they lead to a failure, allowing for proactive servicing. This not only minimizes downtime but also optimizes maintenance schedules, leading to significant cost savings over the generator's lifespan. In my experience, this level of intelligence is becoming a standard expectation from leading generator manufacturers.

Choosing the Right Generator Manufacturer

With so many options available, selecting the right generator can feel overwhelming. But how do you navigate the vast landscape of options to find the perfect fit for your needs? The key is to approach the decision systematically, focusing on your specific requirements and the reputation of the generator manufacturers you are considering. It's not just about the upfront cost; it's about long-term reliability, efficiency, and support.

Many experts agree that a well-chosen generator from a reputable manufacturer is an investment that pays dividends in peace of mind and uninterrupted operation. Conversely, a poor choice can lead to frequent breakdowns, high running costs, and frustration.

Assessing Your Power Needs and Application

Before even looking at specific brands, you need to clearly define your power requirements. This involves:

- Power Output (kW/kVA): Calculate the total wattage of all appliances or equipment you plan to power simultaneously. It's always wise to factor in a little extra capacity for future needs or unexpected surges.

- Fuel Type: Consider the availability and cost of fuel in your location. Diesel is robust and efficient for long-term use, natural gas is convenient if a line is available, and propane is easily stored.

- Application: Is it for emergency backup, prime power for a remote site, or a portable solution for occasional use? This dictates the type of generator (standby, prime, portable) and its features (e.g., automatic transfer switch for standby).

- Noise Levels: For residential or urban settings, a quiet, sound-attenuated enclosure is often a priority.

- Environmental Regulations: Ensure the generator meets local emission standards.

Having a clear understanding of these factors will significantly narrow down your options and help you communicate your needs effectively to potential generator manufacturers or their distributors.

The Value of Reputation and Customer Support

Once you have your technical requirements sorted, turn your attention to the manufacturer's reputation. Look for companies with a proven track record of reliability, innovation, and excellent customer service. This includes:

- Industry Experience: How long have they been in business? Longevity often indicates stability and expertise.

- Certifications and Standards: Do their products comply with international standards (e.g., ISO, UL, EPA)? These certifications are a testament to quality and safety.

- Warranty and Service Network: A strong warranty and a readily accessible service network are crucial. Can you easily get parts and qualified technicians for maintenance and repairs?

- Customer Reviews and Testimonials: What do existing customers say about their products and support? Online reviews and industry forums can provide valuable insights.

I've found that investing in a generator from a reputable manufacturer, even if it means a slightly higher initial cost, almost always pays off in the long run through fewer breakdowns, lower maintenance costs, and superior performance. It's about buying peace of mind, knowing that your power solution is built to last and backed by a company that stands by its products.

In conclusion, the world of generator manufacturers is a fascinating and vital one, constantly innovating to meet the ever-growing demand for reliable power. From the massive industrial powerhouses to the compact, efficient home backup units, these companies are essential partners in ensuring our modern world continues to function, even when the lights go out. Their commitment to engineering excellence, rigorous testing, and continuous innovation means that the future of power generation is in very capable hands.

For more detailed information, please visit our official website:Generator manufacturers

About the author: Dr. Alistair Finch is a seasoned power systems engineer with over two decades of experience in energy infrastructure and industrial power solutions. Holding a Ph.D. in Electrical Engineering, his expertise spans generator design, grid integration, and sustainable energy technologies. Dr. Finch frequently consults for major corporations and government agencies, sharing his insights on reliable power generation and the evolving landscape of energy independence. He is passionate about demystifying complex technical topics for a broader audience.