The Powerhouse Behind Reliability: Navigating the World of Generator Set Manufacturers

Frankly speaking, in an increasingly interconnected and power-dependent world, the continuous supply of electricity isn't just a convenience; it's a fundamental necessity. From ensuring critical operations in hospitals and data centers to powering remote construction sites and providing backup for homes during outages, generator sets play an indispensable role. But who are the entities behind these crucial machines? This is where the expertise of a dedicated Generator set manufacturer comes into play, serving as the backbone of reliable power solutions across countless sectors.

A leading Generator set manufacturer isn't merely an assembler of components; they are innovators, engineers, and problem-solvers. They design, produce, and often maintain the sophisticated machinery that keeps our world running when the grid falters or where it doesn't exist at all. Understanding their operations, the quality they deliver, and the innovations they bring to the table is paramount for anyone seeking robust and dependable power generation equipment.

What Exactly Does a Generator Set Manufacturer Do?

To be honest, the scope of work for a Generator set manufacturer is far more extensive than many realize. It encompasses a complex blend of engineering, manufacturing, quality control, and customer service. They are responsible for transforming raw materials and specialized components into fully functional, reliable power units tailored for diverse applications.

Beyond Assembly: The Core Functions

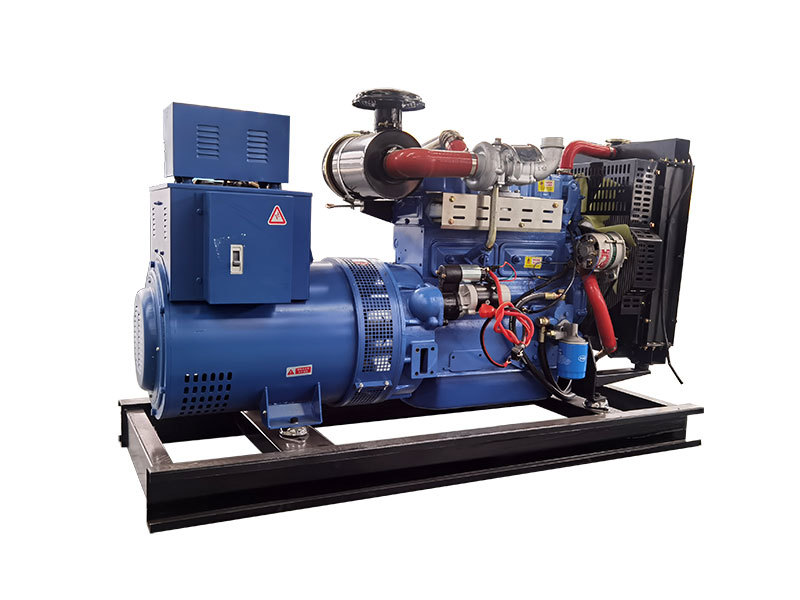

At its core, the work begins with meticulous design and engineering. A reputable manufacturer employs teams of experts who leverage advanced software and deep industry knowledge to conceptualize generator sets that meet specific power requirements, environmental standards, and operational demands. This involves selecting the right engine (often from renowned global brands like Cummins, Perkins, MTU, or Volvo), pairing it with an appropriate alternator (such as Stamford, Leroy-Somer, or Marelli), and integrating a sophisticated control panel that manages and monitors the unit's performance.

Following design, the manufacturing process involves precision fabrication of frames, enclosures, fuel tanks, and exhaust systems. Components are then sourced globally, ensuring high quality and compatibility. The assembly phase is critical, requiring skilled technicians to meticulously put together the engine, alternator, cooling system, fuel system, and electrical controls. Every connection, every weld, and every bolt is crucial for the unit's long-term reliability and safety.

Finally, a significant part of their function involves rigorous testing and quality control. Before any generator set leaves the factory, it undergoes a battery of tests, including load bank testing, insulation resistance checks, and performance validation under various conditions. This ensures that the unit performs exactly as specified and can withstand the demands of its intended application. Interestingly enough, many manufacturers also offer custom solutions, adapting standard designs to meet unique client specifications, whether it's for specific noise reduction levels, extreme weather conditions, or specialized fuel types.

The Spectrum of Power Solutions

Have you ever wondered about the sheer variety of generator sets available? A comprehensive Generator set manufacturer typically offers a wide spectrum of products, categorized by fuel type, power output, application, and mobility. From compact, portable units for small businesses or residential backup to massive industrial generators capable of powering entire facilities, the range is vast. They cater to continuous power needs, standby power for emergencies, and prime power for off-grid operations. This versatility is a testament to the engineering prowess and market understanding of leading manufacturers.

Types of Generator Sets and Their Applications

The world of generator sets is diverse, primarily distinguished by their fuel source and intended use. Each type offers specific advantages, making them suitable for different scenarios. A proficient Generator set manufacturer will specialize in or offer a range of these options to meet varied market demands.

Diesel Generators: The Workhorse of Industry

Diesel generators remain the most popular choice for commercial and industrial applications due to their exceptional reliability, fuel efficiency, and robust performance. They are known for their ability to start quickly and handle heavy loads, making them ideal for critical backup power in hospitals, data centers, and telecommunications. Many industrial power generator suppliers primarily focus on diesel models because of their durability and lower operational costs over the long term, especially in situations requiring extended run times. They are also prevalent on construction sites, mining operations, and in remote locations where grid power is unavailable.

Natural Gas Generators: Cleaner and Cost-Effective

With a growing emphasis on environmental sustainability, natural gas generators have gained significant traction. They produce fewer emissions compared to diesel units, making them a more eco-friendly option. Furthermore, if a natural gas line is readily available, they can offer a continuous and cost-effective fuel supply, eliminating the need for on-site fuel storage and refueling. These units are commonly used for prime power in large commercial buildings, residential complexes, and facilities with access to natural gas infrastructure. Their quieter operation is also a notable advantage in noise-sensitive environments.

Specialized Solutions: From Portable to Prime Power

Beyond diesel and natural gas, manufacturers also produce generators powered by propane, bi-fuel systems, and even renewable energy hybrids. Portable generators are designed for mobility, serving temporary power needs for events, small construction jobs, or residential emergencies. Standby generators are permanently installed and automatically activate upon grid failure, providing seamless power transition for critical applications. Prime power generators are designed to be the primary source of electricity in off-grid locations, running continuously for extended periods. There are also highly specialized units for marine applications, military use, and even mobile power plants, showcasing the adaptability of a skilled Generator set manufacturer.

What Distinguishes a Leading Generator Set Manufacturer?

Choosing the right Generator set manufacturer is a critical decision that impacts the reliability, efficiency, and longevity of your power solution. Several key factors differentiate a top-tier manufacturer from the rest, extending beyond just the product itself to encompass the entire customer experience.

Quality and Reliability: The Non-Negotiables

Frankly speaking, quality is paramount. A leading manufacturer prioritizes the use of high-quality components from globally recognized brands for engines, alternators, and control systems. They implement stringent quality control processes throughout the manufacturing cycle, from initial component inspection to final assembly and testing. Certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), and compliance with international standards like CE, UL, or CSA, are strong indicators of a manufacturer's commitment to excellence. Many experts agree that a manufacturer's reputation for reliability is built on years of consistent performance and minimal product failures in the field.

Innovation and Customization

The power generation landscape is constantly evolving, with new technologies and demands emerging. A forward-thinking manufacturer invests in research and development to incorporate innovations such as advanced digital control systems, remote monitoring capabilities (IoT integration), enhanced fuel efficiency, and reduced emissions. They also excel in offering customization options, understanding that one size does not fit all. Whether it's specific enclosure designs for noise attenuation, specialized fuel tanks, or integration with existing building management systems, the ability to tailor commercial generator set solutions to unique client requirements is a significant advantage.

After-Sales Support and Global Reach

The relationship with a manufacturer doesn't end after the purchase. Comprehensive after-sales support is crucial for the long-term performance and maintenance of a generator set. This includes readily available spare parts, a responsive technical support team, and a robust service network for maintenance and repairs. A manufacturer with a global presence can offer localized support, which is invaluable for international operations. In my experience, the true value of a manufacturer often becomes apparent during the warranty period and beyond, when reliable support can minimize downtime and extend the life of the equipment.

The Manufacturing Process: From Concept to Commissioning

The journey of a generator set from a blueprint to a fully operational power source is a testament to precision engineering and meticulous execution. A leading Generator set manufacturer follows a structured, multi-stage process to ensure every unit meets the highest standards of quality and performance.

Design and Engineering Excellence

It all begins in the design office. Engineers utilize sophisticated CAD (Computer-Aided Design) software and simulation tools to create detailed blueprints of the generator set. This phase involves selecting the optimal engine-alternator combination, designing the cooling system, exhaust system, fuel tank, and the enclosure. Acoustic considerations for noise reduction, vibration dampening, and thermal management are all integrated into the design. The goal is to create a unit that is not only powerful and efficient but also safe, durable, and easy to maintain.

Precision Assembly and Integration

Once the design is finalized and components are sourced, the assembly process commences. This is where skilled technicians meticulously put together hundreds of individual parts. The engine and alternator are mounted onto a robust steel base frame, followed by the integration of the cooling radiator, fuel system, and exhaust system. Electrical wiring for the control panel, safety sensors, and power output connections is carefully installed, adhering to strict electrical codes and standards. Quality checks are performed at every stage of assembly to identify and rectify any potential issues early on.

Rigorous Testing and Quality Assurance

This is arguably the most critical phase. Before any generator set is dispatched, it undergoes comprehensive testing to validate its performance and reliability. This includes load bank testing, where the generator is run at various loads (from 0% to 100% and sometimes even overload) to ensure it can deliver its rated power consistently and efficiently. Parameters such as voltage regulation, frequency stability, fuel consumption, and temperature are closely monitored. Insulation resistance tests, vibration analysis, and noise level measurements are also conducted. For reliable diesel generator producers, this rigorous testing ensures that the unit will perform flawlessly in real-world conditions, providing the peace of mind that comes with a truly dependable power solution.

Navigating the Future: Trends in Generator Set Manufacturing

The power generation industry is not static; it's constantly evolving, driven by technological advancements, environmental concerns, and shifting global demands. A forward-thinking Generator set manufacturer is always looking ahead, integrating new trends to offer more efficient, sustainable, and intelligent power solutions.

Sustainability and Efficiency

The push for greener energy solutions is profoundly impacting generator set manufacturing. We're seeing increased development in units that offer lower emissions, improved fuel efficiency, and the ability to run on alternative fuels like bio-diesel or hydrogen. Hybrid generator sets, which combine traditional generators with renewable energy sources like solar or wind power, are also gaining popularity. These systems optimize fuel consumption and reduce environmental impact, representing a significant step towards more sustainable power generation. I've found that customers are increasingly prioritizing these eco-friendly options, even if they come with a slightly higher initial investment.

Smart Technology and IoT

The integration of smart technology and the Internet of Things (IoT) is revolutionizing how generator sets are monitored and managed. Modern control panels offer advanced diagnostics, predictive maintenance capabilities, and remote monitoring via cloud-based platforms. This allows operators to track performance, identify potential issues before they become critical, and even control units from anywhere in the world. This level of connectivity enhances reliability, reduces downtime, and optimizes operational costs. Interestingly enough, this trend is also making generator sets more adaptable to smart grid integration, allowing them to play a more dynamic role in future energy ecosystems.

Global Demand and Supply Chain Resilience

The global demand for reliable power continues to grow, particularly in developing economies and regions prone to natural disasters. This presents both opportunities and challenges for manufacturers. Building resilient supply chains that can withstand geopolitical shifts, material shortages, and logistical hurdles is becoming increasingly important. Many experts agree that manufacturers who can adapt quickly to market changes, maintain diverse sourcing strategies, and ensure robust production capabilities will be the ones to thrive in this dynamic environment. The ability to deliver solutions globally, often requiring adherence to various regional standards and regulations, is also a key differentiator.

In conclusion, the role of a Generator set manufacturer is undeniably pivotal in our modern world. They are the architects of power reliability, ensuring that essential services, industries, and communities remain operational, regardless of external power conditions. From the meticulous design and engineering to the rigorous testing and comprehensive after-sales support, every aspect of their operation is geared towards delivering dependable power solutions. As technology advances and global energy demands evolve, these manufacturers will continue to innovate, providing the robust and intelligent power systems that drive progress and secure our future.

For more detailed information, please visit our official website:Generator set manufacturer

About the author: Dr. Alistair Finch is a seasoned expert in industrial power solutions with over two decades of experience in the energy sector. Holding a Ph.D. in Electrical Engineering, his work focuses on the design, deployment, and optimization of generator sets for critical applications. He frequently consults for leading manufacturers and has published numerous papers on power reliability and sustainable energy systems. Dr. Finch is passionate about demystifying complex power technologies and empowering businesses to make informed energy decisions.