Powering Progress: A Manufacturer\'s Deep Dive into Diesel vs. Natural Gas for Industrial Needs

In the dynamic world of manufacturing, the choice of industrial power is far more than a mere technical specification; it's a strategic decision that impacts everything from operational costs and environmental compliance to long-term reliability and market competitiveness. For decades, diesel has been the undisputed king of industrial power, revered for its robustness and immediate power delivery. However, with evolving energy landscapes, stricter environmental regulations, and advancements in natural gas technology, manufacturers are increasingly weighing their options. This article provides a comprehensive, manufacturer's in-depth comparison of diesel vs. natural gas for your industrial power needs, offering insights to guide your critical decisions.

Frankly speaking, there's no one-size-fits-all answer. The optimal fuel choice depends heavily on your specific operational demands, geographical location, regulatory environment, and long-term business objectives. As a manufacturer, you're not just buying an engine; you're investing in a power ecosystem. Let's delve into the core aspects that define this pivotal comparison.

Performance, Reliability, and Power Delivery: The Heart of Your Operations

When it comes to keeping a factory running, performance and reliability are paramount. Downtime translates directly into lost revenue and damaged reputation. Both diesel and natural gas engines offer distinct advantages in this arena, and understanding these nuances is crucial for any industrial operation.

Peak Load Handling and Transient Response

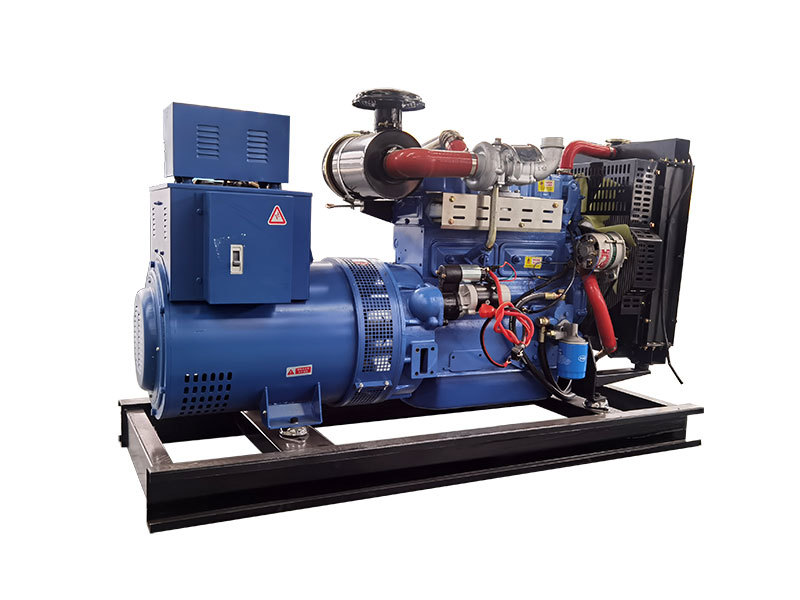

Diesel engines have historically excelled at handling sudden, large load changes. Their ability to deliver instant torque and rapid power ramp-up makes them ideal for applications requiring quick starts and stops, or for backup power where immediate full load acceptance is critical. In my experience, a diesel generator can go from a cold start to full power in mere seconds, which is a significant advantage for emergency standby power or processes with highly fluctuating power demands. This robust transient response is a hallmark of diesel technology, making it a go-to for critical infrastructure and peak shaving applications.

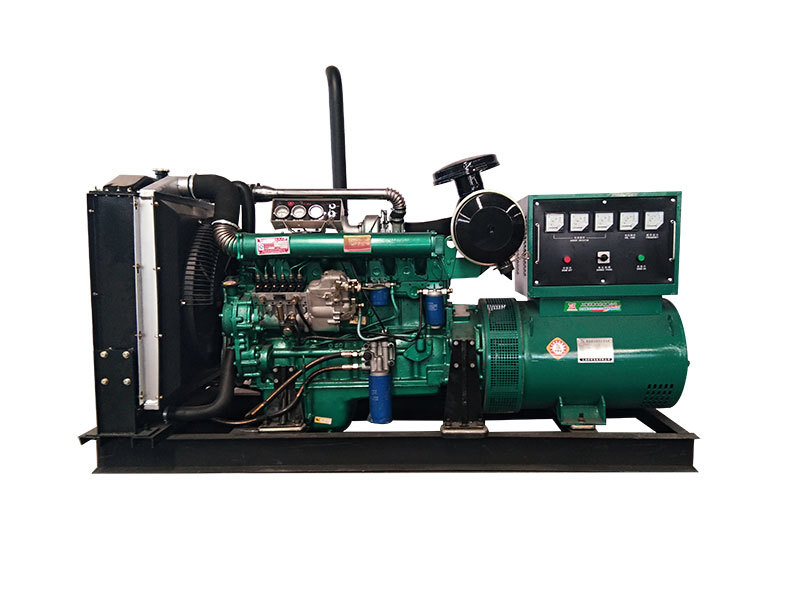

Natural gas engines, while continuously improving, traditionally have a slightly slower transient response compared to their diesel counterparts. They are generally better suited for continuous, stable power generation. However, modern natural gas engines, especially those designed for industrial use, have sophisticated control systems that significantly mitigate this difference, allowing for much quicker load acceptance than older models. It's worth noting that for primary power generation where the load is relatively stable, the difference in transient response often becomes negligible.

Uptime and Maintenance Cycles

Reliability isn't just about how quickly an engine starts; it's about how consistently it runs. Diesel engines are renowned for their durability and long operational lifespans, often requiring less frequent major overhauls compared to some natural gas counterparts, especially in very high-hour applications. Their robust construction is designed to withstand demanding industrial environments. However, diesel engines typically require more frequent routine maintenance, such as oil changes and filter replacements, due to the nature of diesel combustion and fuel impurities.

Natural gas engines, on the other hand, often boast cleaner combustion, which can lead to less carbon buildup and potentially extended intervals between certain maintenance tasks. Interestingly enough, while the maintenance *tasks* might be less frequent for some components, the complexity of natural gas engine systems (e.g., ignition systems, precise air-fuel ratio controls) can sometimes mean that when maintenance *is* required, it might involve more specialized skills or components. Many experts agree that the lifespan of a well-maintained natural gas engine can rival that of a diesel engine, particularly when operating continuously at optimal loads.

The Economic Equation: Costs, Fuel, and ROI

For any manufacturer, the bottom line is paramount. The initial investment, ongoing operational costs, and long-term return on investment (ROI) are critical factors in the Diesel vs. Natural Gas: A Manufacturer's In-Depth Comparison for Your Industrial Power Needs. This isn't just about the price tag of the engine; it encompasses fuel costs, maintenance, infrastructure, and even potential regulatory penalties.

Fuel Price Volatility and Supply Chains

Perhaps the most significant variable in the economic equation is fuel cost. Diesel prices are notoriously volatile, influenced by global oil markets, geopolitical events, and refining capacities. While diesel is easily transportable and stored, its price fluctuations can make long-term budgeting challenging. Manufacturers reliant on diesel often face unpredictable operational expenses, which can impact profitability and pricing strategies.

Natural gas, especially in regions with abundant domestic supply (like North America), has historically been more stable and often significantly cheaper than diesel on an energy-equivalent basis. The supply chain for natural gas is typically through pipelines, which offers a continuous and reliable flow, reducing logistical complexities associated with fuel deliveries. However, natural gas prices can also fluctuate, especially seasonally, and availability might be an issue in remote areas without pipeline infrastructure. To be honest, assessing the long-term trend of both fuel types in your specific region is absolutely critical.

Maintenance Regimes and Lifespan

Beyond fuel, maintenance costs contribute significantly to the total cost of ownership. As mentioned, diesel engines might require more frequent routine servicing due to fuel characteristics and combustion byproducts. Parts for diesel engines are generally widely available, and technicians are abundant.

Natural gas engines, while potentially having longer intervals between certain types of maintenance, might incur higher costs for specialized components or diagnostics when issues do arise. The complexity of their control systems can sometimes lead to more intricate troubleshooting. However, the cleaner burn of natural gas often translates to less wear on internal components over the long run, potentially extending engine life and reducing the frequency of major overhauls. When considering optimizing industrial energy costs, a thorough lifecycle cost analysis, including both fuel and maintenance, is indispensable.

Environmental Footprint and Regulatory Compliance

In today's world, environmental responsibility is not just good practice; it's often a legal and market imperative. The environmental impact of your chosen power source can significantly influence your brand image, regulatory compliance, and even access to certain markets or financing. This aspect is increasingly central to the Diesel vs. Natural Gas: A Manufacturer's In-Depth Comparison for Your Industrial Power Needs.

Emissions Profile: A Closer Look

This is where natural gas typically shines. Natural gas combustion produces significantly lower emissions of nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM) compared to diesel. Sulfur, a major contributor to acid rain and respiratory issues, is virtually absent in natural gas. While both fuels produce carbon dioxide (CO2), natural gas combustion generally results in lower CO2 emissions per unit of energy produced compared to diesel. This makes natural gas a more attractive option for manufacturers striving for a smaller carbon footprint and better air quality.

Diesel engines, especially older models, produce higher levels of these pollutants. Modern diesel engines, however, have made significant strides with advanced emission control technologies like Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) systems. These technologies drastically reduce harmful emissions, allowing diesel engines to meet stringent environmental regulations. However, these systems add to the complexity, cost, and maintenance requirements of the diesel unit.

Navigating Environmental Regulations

Regulatory landscapes are constantly evolving. Governments worldwide are imposing stricter emission standards, particularly in urban and industrial areas. For manufacturers, compliance is non-negotiable. Natural gas engines often have an easier time meeting current and future emission standards without extensive after-treatment systems, potentially simplifying permitting and long-term operational compliance. This is a key consideration for sustainable manufacturing power.

Diesel engines, while capable of meeting regulations with advanced technology, might face more hurdles or require more frequent testing and reporting. Some regions even offer incentives or tax breaks for adopting cleaner energy sources, which could further tip the scales in favor of natural gas. Have you ever truly weighed the long-term implications of evolving environmental regulations on your industrial engine fuel choice? It's a factor that can dramatically alter your operational costs and public perception.

Infrastructure, Installation, and Site Considerations

Beyond the engine itself, the logistical and infrastructural requirements play a huge role in the feasibility and cost-effectiveness of your power solution. This includes everything from fuel storage to site preparation and permitting.

Fuel Storage and Delivery

This is one of the most stark differences. Diesel requires on-site fuel storage tanks, which necessitate considerable space, adherence to strict environmental regulations for spill prevention, and regular fuel deliveries. While diesel tanks offer energy independence and portability, they also come with security risks, potential for leaks, and the need for inventory management.

Natural gas, conversely, typically relies on a direct pipeline connection to your facility. This eliminates the need for on-site fuel storage, freeing up valuable space and removing the logistical burden of fuel deliveries. The continuous supply through a pipeline offers a highly reliable and convenient fuel source. However, the initial installation of a pipeline connection can be costly and time-consuming, depending on your proximity to existing gas lines. For manufacturers in remote locations, access to a natural gas pipeline might be non-existent, making diesel the only viable option.

Site Footprint and Permitting

The overall footprint of your power generation system is another important consideration. Diesel generator sets, especially those with large fuel tanks, can require significant space. Permitting for diesel storage and operation can also be complex, involving fire safety regulations, environmental impact assessments, and local zoning laws.

Natural gas systems generally have a smaller physical footprint as they don't require large fuel tanks. The permitting process for natural gas might focus more on pipeline connections and gas safety protocols rather than large-scale fuel storage. However, the installation of gas lines and specialized equipment can still involve significant engineering and regulatory approvals. Frankly speaking, understanding the local permitting environment for both fuel types is crucial before making a commitment.

Strategic Decision-Making: A Manufacturer's Perspective

Bringing all these factors together, the decision between diesel and natural gas for your industrial power needs becomes a strategic exercise. It’s about aligning your energy solution with your long-term business goals, risk tolerance, and commitment to sustainability.

Balancing Immediate Needs with Future Vision

In my experience, many manufacturers prioritize immediate cost savings or rapid deployment. Diesel often wins on upfront capital expenditure and speed of installation, especially for smaller or temporary power needs. However, the long-term operational costs, particularly fuel price volatility and evolving environmental regulations, can quickly erode those initial savings.

Conversely, natural gas, while potentially requiring a higher initial investment for infrastructure, can offer more stable and lower operational costs over its lifespan, coupled with a cleaner environmental profile. This makes it a strong contender for manufacturers focused on sustainable manufacturing power and long-term cost predictability. The choice often boils down to whether you're optimizing for short-term flexibility or long-term efficiency and environmental stewardship.

Consider your industry's specific demands. Is your operation highly sensitive to power interruptions, demanding instant backup? Diesel’s rapid response might be irreplaceable. Do you run continuous, base-load operations where consistent, cost-effective power is key? Natural gas could be your champion. For a comprehensive Diesel vs. Natural Gas: A Manufacturer's In-Depth Comparison for Your Industrial Power Needs, it's vital to model various scenarios.

Redundancy, Hybrid Solutions, and Future-Proofing

Interestingly enough, the conversation isn't always about choosing one over the other. Many forward-thinking manufacturers are exploring hybrid solutions, combining the strengths of both. A natural gas primary power system could be backed up by a smaller diesel generator for critical loads during outages, offering the best of both worlds: clean, cost-effective primary power with robust emergency redundancy. This approach can also involve integrating renewable energy sources, further diversifying your energy portfolio and enhancing resilience.

When considering your industrial engine fuel choice, think about future-proofing. What are the likely trends in energy prices, environmental regulations, and technological advancements? Investing in a solution that offers adaptability and scalability can save significant costs down the line. What's your primary driver when considering industrial power – upfront cost, environmental impact, or long-term reliability? Your answer will heavily influence the optimal path.

Charting Your Industrial Power Future

Ultimately, the decision between diesel and natural gas for your industrial power needs is a complex one, requiring a holistic evaluation of performance, economics, environmental impact, and infrastructure. Both fuel types offer compelling advantages depending on the specific context of your manufacturing operation.

Diesel remains a powerful, reliable choice for applications demanding instant power and robust performance, especially where natural gas infrastructure is unavailable or for critical backup. Its proven track record and ease of transport are undeniable strengths.

Natural gas, with its cleaner emissions profile, often lower and more stable fuel costs, and continuous pipeline supply, is increasingly becoming the preferred option for primary power generation and for manufacturers committed to sustainability and long-term operational efficiency.

As a manufacturer, your objective is to ensure uninterrupted, cost-effective, and responsible power for your operations. A thorough analysis, perhaps with the guidance of energy experts, will help you navigate this critical decision and select the power solution that best aligns with your strategic vision. The right choice will not only power your machines but also propel your business forward.

For more detailed information, please visit our official website:industrial power solutions

About the author: Johnathan "J.T." Thompson is a seasoned industrial energy consultant with over 20 years of experience in power generation and manufacturing operations. Specializing in fuel efficiency and sustainable energy solutions, J.T. has advised countless manufacturers on optimizing their industrial power needs. His practical insights and deep understanding of engine technology make him a trusted voice in the field of industrial energy management.