Beyond the Blackout: An Engineer\'s Guide to Proactive Generator Set Maintenance

Views :

Update time : 2025-06-09

In our increasingly interconnected world, reliable power isn't just a convenience; it's a fundamental necessity. From hospitals and data centers to manufacturing plants and critical infrastructure, the stakes are incredibly high when the grid falters. This is precisely where generator sets step in, acting as the silent guardians of continuity. But here's the thing: a generator is only as good as its maintenance. Frankly speaking, waiting for a power outage to discover your generator isn't ready is a scenario no engineer wants to face. This comprehensive guide, Beyond the Blackout: An Engineer's Guide to Proactive Generator Set Maintenance, aims to equip you with the knowledge and strategies to ensure your power systems are always ready, always reliable.

Have you ever wondered what truly sets apart a resilient operation from one vulnerable to power interruptions? It's often the meticulous attention paid to proactive generator set maintenance. In my experience, neglecting this critical aspect is a common oversight that leads to costly downtime, equipment failure, and even safety hazards. This article will delve deep into the core principles and practical steps required to move beyond reactive fixes and embrace a truly proactive approach.

The Imperative of Proactive Generator Maintenance: Why Waiting is Not an Option

It's worth noting that many organizations view generator maintenance as a necessary evil, a cost center rather than a strategic investment. To be honest, this perspective couldn't be more misguided. The true value of a generator set lies in its ability to perform flawlessly when called upon, often under stressful conditions. A reactive approach, where you only address issues after a breakdown, is a recipe for disaster. It's not just about the immediate cost of repairs; it's about the cascading impact of lost productivity, data corruption, spoiled goods, or even compromised patient care. Think about it: when a generator fails during a critical power outage, the financial repercussions can be staggering. Beyond direct repair costs, you face potential regulatory fines, reputational damage, and the loss of customer trust. Furthermore, repeated failures can significantly shorten the lifespan of your expensive equipment, leading to premature replacement. This is where the concept of Beyond the Blackout: An Engineer's Guide to Proactive Generator Set Maintenance truly shines. By shifting from a "fix-it-when-it-breaks" mentality to a "prevent-it-from-breaking" strategy, you safeguard your assets, enhance operational efficiency, and ensure unparalleled emergency power system reliability. Many experts agree that proactive maintenance is not just about avoiding failure; it's about optimizing performance and extending the life of your investment.Key Components and Their Maintenance Needs: A Deep Dive

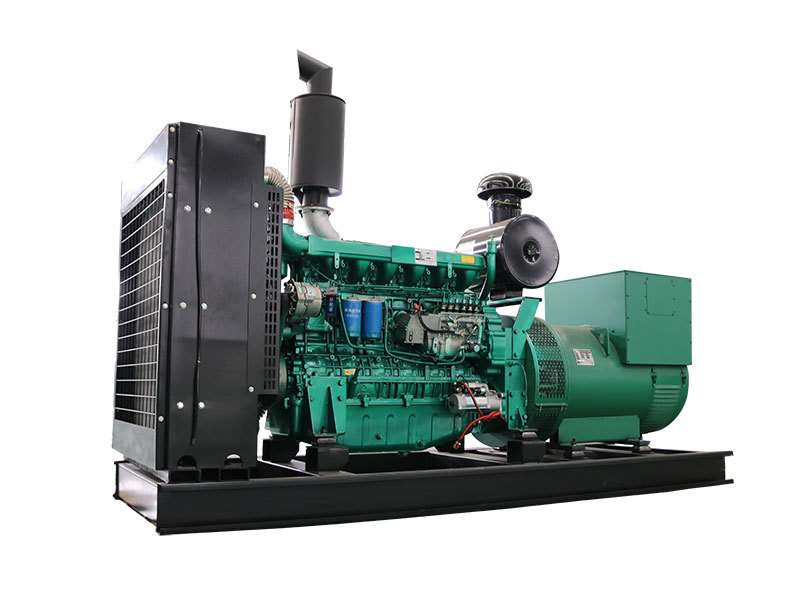

A modern generator set is a complex piece of machinery, an intricate dance of mechanical, electrical, and control systems. Each component plays a vital role, and understanding their individual maintenance requirements is crucial for comprehensive proactive generator set care.Engine System: The Heartbeat of Your Generator

The engine is, without a doubt, the core of your generator. Its health dictates the overall reliability.- Oil and Filter Changes: Just like a car, the engine oil lubricates moving parts and dissipates heat. Regular oil and filter changes, adhering to manufacturer specifications (often based on operating hours or calendar time), are paramount. Contaminated or degraded oil can lead to excessive wear and premature engine failure.

- Air Filter Inspection and Replacement: A clean air filter is essential for proper combustion. A clogged filter restricts airflow, leading to reduced power output, increased fuel consumption, and potential engine damage. Inspect regularly and replace as needed, especially in dusty environments.

- Fuel System Checks: Fuel quality is a major concern. Diesel fuel can degrade over time, leading to sludge and microbial growth. Regularly inspect fuel lines for leaks, check fuel filters for contamination, and consider fuel polishing or additives for stored fuel.

- Cooling System Maintenance: The cooling system prevents the engine from overheating. This involves checking coolant levels, inspecting hoses and belts for wear, and ensuring the radiator fins are clean and free of obstructions. Periodically, the coolant itself needs to be flushed and replaced.

Electrical System: The Power Pathway

The electrical components are responsible for generating and distributing power.- Battery Health: The starting battery is often the most overlooked component, yet it's critical for starting the generator. Check battery terminals for corrosion, ensure connections are tight, and test battery voltage and load capacity regularly. A weak battery is a common cause of generator start failures.

- Alternator Inspection: Inspect the alternator for signs of wear, such as worn bearings or brushes (if applicable). Ensure proper ventilation around the alternator.

- Wiring and Connections: Vibrations and environmental factors can loosen electrical connections. Periodically inspect all wiring for fraying or damage and ensure all connections are tight and secure.

Control Panel and Instrumentation: Your Generator's Brain

The control panel monitors generator performance and provides critical operational data.- Functionality Checks: Regularly test all alarms, shutdowns, and automatic transfer switch (ATS) functions. Ensure all gauges and indicators are working correctly.

- Firmware Updates: For modern, digitally controlled generators, ensure firmware is up-to-date to benefit from bug fixes and performance enhancements.

Developing a Robust Maintenance Schedule: The Backbone of Reliability

Establishing a clear, consistent maintenance schedule is the cornerstone of effective proactive generator set maintenance. This isn't a one-size-fits-all solution; it needs to be tailored to your specific generator model, its operating environment, and its typical usage patterns. However, there are general guidelines that form the backbone of any good maintenance program.Daily/Weekly Checks (Visual & Basic Functionality)

These are quick, routine checks that can often be performed by on-site personnel.- Visual Inspection: Look for leaks (fuel, oil, coolant), loose connections, damaged hoses, or unusual wear.

- Fluid Levels: Check engine oil, coolant, and fuel levels. Top up as needed.

- Battery Charger: Verify the battery charger is operating correctly and the battery voltage is within specification.

- Control Panel: Check for any active alarms or fault codes.

- Run Test (Weekly/Bi-Weekly): Perform a short, unloaded or lightly loaded run test (e.g., 30 minutes). This helps circulate fluids, lubricate seals, and confirm the generator starts and runs smoothly. This is a critical aspect of industrial generator maintenance best practices.

Monthly/Quarterly Checks (More Detailed Inspections)

These require a bit more time and technical expertise.- Fuel System: Drain any water or sediment from the fuel tank and fuel filters. Inspect fuel lines.

- Cooling System: Check coolant concentration and pH. Inspect radiator fins for obstructions and clean if necessary.

- Air Filter: Inspect and clean or replace the air filter as needed.

- Exhaust System: Check for leaks, cracks, or excessive carbon buildup.

- Electrical Connections: Inspect and tighten all major electrical connections.

Annual/Bi-Annual Checks (Comprehensive Servicing)

These are typically performed by certified technicians and involve more in-depth procedures.- Oil and Filter Change: Comprehensive engine oil and filter replacement.

- Fuel Filter Replacement: Replace all fuel filters.

- Coolant Flush and Replacement: Flush the cooling system and replace coolant.

- Valve Lash Adjustment: Check and adjust engine valve lash if required by the manufacturer.

- Load Bank Testing: This is arguably one of the most vital annual tests. A load bank test simulates a real-world load on the generator, allowing you to confirm its ability to deliver its rated power under sustained conditions. It helps burn off wet stacking (unburnt fuel and carbon buildup) and identifies potential weaknesses that wouldn't show up in an unloaded run test.

Advanced Diagnostics and Predictive Maintenance: Looking Beyond the Obvious

While scheduled maintenance is crucial, the true frontier of Beyond the Blackout: An Engineer's Guide to Proactive Generator Set Maintenance lies in advanced diagnostics and predictive maintenance technologies. These tools allow engineers to peer into the operational health of a generator, often identifying potential issues long before they manifest as failures. This approach minimizes downtime, optimizes maintenance schedules, and reduces overall operational costs.Fluid Analysis: The Blood Test for Your Generator

Regular analysis of engine oil, coolant, and fuel can provide invaluable insights into the internal condition of your generator.- Oil Analysis: This can detect wear metals (indicating component wear), contaminants (like fuel, coolant, or dirt), and the condition of the oil itself. For instance, high levels of iron might suggest bearing wear, while silicon could indicate a compromised air filter.

- Coolant Analysis: This checks for proper chemical balance, contamination, and the presence of corrosion inhibitors. It can reveal issues like cavitation, scaling, or even early signs of head gasket leaks.

- Fuel Analysis: Essential for stored fuel, this tests for water content, microbial growth, and fuel degradation, all of which can severely impact engine performance and lead to filter clogging.

Thermography (Infrared Imaging): Spotting the Hot Spots

Infrared cameras can detect abnormal heat signatures in electrical connections, bearings, and other components. Overheating often indicates increased resistance, loose connections, or impending mechanical failure. Identifying these hot spots early allows for targeted repairs before a component fails catastrophically.Vibration Analysis: Listening to Your Generator's Pulse

Every rotating machine produces a unique vibration signature. Changes in this signature can indicate issues like bearing wear, misalignment, or imbalance. By monitoring vibration levels over time, engineers can predict component failures and schedule maintenance proactively, avoiding unexpected breakdowns.Remote Monitoring and Telematics: Real-time Insights

Modern generator sets can be equipped with remote monitoring systems that transmit real-time operational data (e.g., engine temperature, oil pressure, fuel level, battery voltage, fault codes) to a central location or even a mobile app. This allows engineers to:- Monitor performance from anywhere.

- Receive instant alerts for anomalies.

- Track fuel consumption and operating hours.

- Diagnose issues remotely, potentially reducing the need for immediate on-site visits.

Common Pitfalls and How to Avoid Them: Lessons from the Field

Even with the best intentions, certain pitfalls can undermine even the most robust proactive generator set maintenance programs. Recognizing these common errors is the first step toward avoiding them.Neglecting Fuel Quality and Management

This is, perhaps, the most frequent culprit behind generator failures, especially for units that sit idle for extended periods. Diesel fuel degrades, collects water, and can foster microbial growth (diesel bug).- Solution: Implement a strict fuel management plan. This includes regular fuel polishing, using appropriate fuel stabilizers, and ensuring tanks are kept full to minimize condensation. Always source fuel from reputable suppliers.

Ignoring Alarms and Warning Indicators

Modern generators are equipped with sophisticated control panels that provide a wealth of diagnostic information. Ignoring persistent alarms or warning lights is akin to driving a car with the check engine light on – it's an invitation for trouble.- Solution: Train personnel to recognize and report all alarms immediately. Establish clear protocols for alarm response, distinguishing between critical shutdowns and warning indicators that require prompt investigation.

Improper or Insufficient Load Testing

As mentioned earlier, an unloaded run test isn't enough. Generators need to be exercised under load to prevent "wet stacking" and ensure all components are stressed as they would be in a real outage.- Solution: Schedule regular load bank testing, ideally annually, for at least 2-4 hours at a significant percentage of the generator's rated capacity. This is a non-negotiable part of industrial generator maintenance best practices.

Lack of Qualified Personnel and Training

A maintenance program is only as effective as the people executing it. Relying on untrained staff or generic maintenance schedules can lead to missed issues or incorrect procedures.- Solution: Invest in regular training for your in-house team, or partner with certified generator service providers. Ensure technicians are familiar with your specific generator models and the latest maintenance techniques.

Overlooking Environmental Factors

The operating environment significantly impacts generator longevity and performance. Extreme temperatures, dust, humidity, and corrosive atmospheres can accelerate wear and tear.- Solution: Ensure proper ventilation, temperature control, and filtration for the generator enclosure. Regularly clean the generator and its surroundings to prevent dust and debris buildup. Consider specialized coatings or enclosures for harsh environments.

Embracing a Culture of Readiness: The Ultimate Goal

Ultimately, Beyond the Blackout: An Engineer's Guide to Proactive Generator Set Maintenance is about more than just checking boxes on a maintenance list. It's about cultivating a culture of readiness within your organization. It's about understanding that your generator set isn't just a piece of equipment; it's a critical lifeline that protects your operations, your data, your reputation, and most importantly, the safety of those who depend on your power supply. By meticulously adhering to proactive maintenance schedules, leveraging advanced diagnostic tools, and continuously training your team, you transform your generator from a potential liability into a reliable asset. This isn't just about avoiding a blackout; it's about ensuring seamless continuity, peace of mind, and the sustained resilience of your entire operation. The investment in proactive care pays dividends far beyond the cost of a repair, ensuring that when the grid goes down, your operations stay up.For more detailed information, please visit our official website:Generator set maintenance

About the author: Johnathan "Jon" Power is a seasoned mechanical engineer with over 20 years of experience specializing in power generation systems. His expertise spans industrial generator design, installation, and, crucially, proactive maintenance strategies. Jon is passionate about helping organizations achieve unparalleled power reliability, having guided numerous companies through complex maintenance overhauls and emergency preparedness planning. He believes that a well-maintained generator is the silent hero of modern infrastructure.

Related News

2025 Power Grid Alert: How Facility Engi

Dec .11.2025

Discover actionable strategies for facility engine...

Top Diesel Genset Manufacturers in China

Dec .09.2025

Discover the top diesel genset manufacturers in Ch...

Genset 101: The Ultimate Guide to Unders

Dec .09.2025

Genset 101: The Ultimate Guide to Understanding, C...

Beyond the Box: How to Find a Reliable G

Dec .03.2025

Searching for a reliable generator set manufacture...