Reliable power is the backbone of many operations, from manufacturing plants and data centers to hospitals and critical infrastructure. When the grid goes down, an industrial generator set isn't just a convenience; it's a necessity for maintaining continuity, preventing costly downtime, and ensuring safety. But for anyone tasked with acquiring this vital equipment, one of the first and most significant questions that arises is: what is the true industrial generator set price? This isn't a simple question with a single answer. The cost can vary dramatically based on a multitude of factors, making the purchasing process complex. Understanding these variables is crucial for budgeting accurately, evaluating proposals effectively, and ultimately securing a power solution that meets your specific needs without unnecessary expenditure or, perhaps worse, insufficient capability. Frankly speaking, diving into the market without a clear understanding of what drives costs can lead to poor decisions and unexpected future expenses.

Decoding the Cost of Industrial Power Solutions

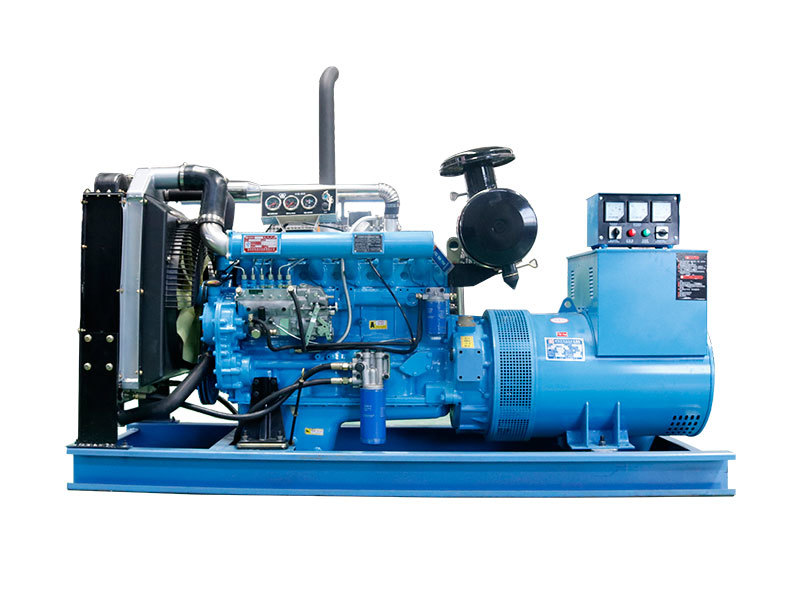

When you start looking into the cost of backup or prime power, you quickly discover that the initial price tag for an industrial generator set is just the tip of the iceberg. Many elements contribute to the overall expense, and these go far beyond the basic engine and alternator. Everything from the power output required to the specific features needed for integration into your existing system plays a significant role. Think about the environment where the generator will operate – will it be indoors, requiring ventilation and exhaust systems? Or outdoors, necessitating a weather-resistant and potentially sound-attenuated enclosure? These practical considerations directly influence the final industrial generator set price. Furthermore, the intended use—whether for emergency standby, continuous prime power, or peak shaving—dictates required runtime capabilities and control complexities, adding layers to the cost structure. It's worth noting that seemingly small details can have a surprisingly large impact on the budget, making a thorough needs assessment absolutely essential before even requesting quotes.

Key Technical Factors Influencing Industrial Generator Pricing

At the heart of determining an industrial generator set price are the technical specifications. The most significant is typically the power output, measured in kilowatts (kW) or kilovolt-amperes (kVA). A generator designed to power a small server room will naturally cost far less than one needed to run an entire factory or hospital wing during an outage. The engine is another primary cost driver; larger, more robust engines capable of sustained high output are inherently more expensive than smaller ones. The fuel type also presents a critical cost distinction. Diesel generators are incredibly common due to their reliability and power density, but the initial cost of industrial diesel generator units can sometimes be higher than their natural gas counterparts, though this often depends on size and features. Natural gas generators offer advantages in terms of potentially lower emissions and easier fuel availability via pipeline, but they may have different power delivery characteristics and require specific site infrastructure which adds to the overall project cost. Understanding the interplay between power requirements, engine size, and fuel source is fundamental to estimating the potential investment.

The Impact of Brand Reputation and Manufacturing Quality

Just like with vehicles or appliances, the manufacturer's brand name and the quality of construction significantly influence the industrial generator set price. Established manufacturers with decades of experience and a proven track record for reliability and durability typically command higher prices than newer or lesser-known brands. Why is this the case? Because you're often paying for the peace of mind that comes with superior engineering, higher-quality components (like alternators, control systems, and circuit breakers), rigorous testing standards, and better overall build quality. A generator from a reputable brand is less likely to fail when you need it most and is often designed to last longer, providing a better return on investment over its lifespan. While a lower initial price might be tempting, opting for a unit with cheaper components or less stringent manufacturing processes could lead to more frequent breakdowns, higher maintenance costs, and shorter service life down the road. Many experts agree that investing in a quality build from a trusted name is a critical factor in ensuring long-term operational success.

Features, Enclosures, and Customization Costs

Beyond the basic power generation components, industrial generator sets can be equipped with a vast array of features and options, each adding to the overall cost. Control panels range from basic manual start/stop systems to sophisticated digital controllers with advanced monitoring, diagnostics, and remote management capabilities. Automatic Transfer Switches (ATS) are essential for standby power applications, enabling the generator to start and switch the load automatically when utility power fails; the size and complexity of the ATS correlate directly with price. Enclosures for outdoor installation provide protection from weather and physical damage, and sound-attenuated enclosures are often required in urban or noise-sensitive areas, significantly increasing the price due to specialized materials and design. Other options include larger fuel tanks, trailers for mobility, paralleling gear to combine multiple generators, exhaust emission reduction systems, and specialized circuit protection. Customization for specific applications or unusual site conditions can also add substantial engineering and manufacturing costs. Therefore, carefully evaluating which features are truly necessary versus those that are merely desirable is key to managing the final industrial generator set price effectively.

Calculating Beyond the Initial Generator Set Price

Anyone focused solely on the sticker price of the generator set itself is missing a large part of the financial picture. The total cost of implementing an industrial power solution includes significant expenses beyond the equipment purchase. Site preparation is often necessary, potentially involving excavation, concrete pads for mounting, fencing, and landscaping. The installation process itself requires skilled labor, electrical work to connect to the building's distribution system and the ATS, and potentially mechanical work for fuel lines, exhaust, and ventilation. Obtaining necessary permits from local authorities can involve fees and meeting specific building codes or environmental regulations. Transportation costs, especially for large units, must also be factored in. Frankly speaking, these associated costs can sometimes equal or even exceed the purchase price of the generator set, depending on the complexity of the installation and the existing site conditions. It's vital to get detailed quotes that break down these additional expenses when evaluating the true investment required.

The Long-Term Financial View: Total Cost of Ownership

A truly comprehensive evaluation of an industrial generator set price must include the total cost of ownership (TCO) over the unit's expected lifespan. This goes far beyond the initial purchase and installation costs. Fuel consumption is a major ongoing expense, particularly for units used for prime power or frequent, extended standby periods. Maintenance requirements—including routine service, oil changes, filter replacements, and periodic inspections—are necessary to keep the generator running reliably and can add up over time. Parts and labor for repairs, should they be needed, also contribute to the TCO. The lifespan of the generator set, influenced by its quality and maintenance, directly impacts the annual depreciation and when a replacement might be necessary. When considering the cost of industrial diesel generator ownership, for instance, fluctuating diesel prices can have a significant impact on operating budgets. Evaluating the TCO allows businesses to compare different generator options not just on their upfront cost, but on their long-term financial impact, often revealing that a slightly higher initial investment in a more fuel-efficient or durable unit can result in substantial savings over a decade or more.

Strategies for Navigating the Industrial Generator Market

Given the numerous variables, navigating the market to determine a realistic industrial generator set price requires a strategic approach. First, accurately assess your power needs. What is the total load (kW/kVA) that needs to be supported? Are there critical loads that must always have power, separate from non-essential ones? What is the intended use (standby, prime, continuous)? Understanding these requirements is the foundational step. Next, research reputable manufacturers and suppliers. Seek out companies with experience in industrial applications similar to yours. When requesting quotes, provide detailed specifications of your power needs, site conditions, and any desired features or compliance requirements. Don't hesitate to ask clarifying questions about what is included in the price and what is not. It's often beneficial to get quotes from multiple vendors to compare pricing, but remember to compare apples to apples—ensure quotes are based on similar quality levels, features, and scope of work (including installation and commissioning). Factors affecting industrial generator pricing can be complex, and a good supplier will help you understand these nuances rather than just providing a number.

The Value of Expertise in Selecting the Right Solution

Selecting the appropriate industrial generator set goes beyond simply finding the lowest initial industrial generator set price. It requires expertise in electrical load calculation, understanding of applicable codes and regulations, knowledge of different fuel sources and their implications, and insight into the long-term reliability and maintenance needs of various units. Working with a knowledgeable supplier or consultant can be invaluable. They can help you accurately size the generator, recommend the most suitable fuel type and features for your specific application, and navigate the complexities of installation and permitting. A good partner will take the time to understand your operational priorities – whether that's minimizing downtime, optimizing fuel efficiency, reducing emissions, or ensuring quiet operation – and propose solutions that align with those goals and your budget. They can often provide a detailed breakdown of the total project cost, including installation and commissioning, offering a clearer picture than just the generator price alone. Frankly speaking, getting it wrong can be an expensive mistake, leading to oversized or undersized units, compliance issues, or frequent operational problems.

Investing Wisely: Balancing Price and Performance

Ultimately, determining the right industrial generator set price for your needs isn't about finding the cheapest option; it's about finding the best value. This means balancing the initial investment with the required performance, reliability, and long-term operating costs. A high-quality, well-maintained generator set from a reputable manufacturer can provide reliable power for decades, minimizing downtime and protecting your operations and assets. While the upfront cost may be higher, the reduced risk of failure, lower maintenance frequency, and potentially better fuel efficiency can result in significant savings over the unit's operational life compared to a cheaper, less robust alternative. Have you considered the potential financial impact of an extended power outage if your backup system fails? For many businesses and facilities, this cost far outweighs the premium paid for a reliable generator. Therefore, view the purchase not just as an expense, but as a critical investment in business continuity and operational resilience. Getting this decision right is paramount.

Understanding the factors that influence the industrial generator set price, from technical specifications and brand quality to installation complexities and total cost of ownership, is essential for making an informed purchasing decision. It's not just about the initial tag but the long-term reliability and value the generator provides. Accurate load assessment, careful consideration of features, and a thorough understanding of all associated costs are crucial steps. Partnering with experienced professionals can help navigate these complexities, ensuring you select a power solution that not only fits your budget but, more importantly, reliably meets your critical power needs for years to come. Taking the time to properly evaluate your options and understand the true investment will pay dividends in preventing costly disruptions and ensuring operational resilience. Make sure you're not just buying a generator, but investing in dependable power security.

For more detailed information, please visit our official website: industrial generator set price