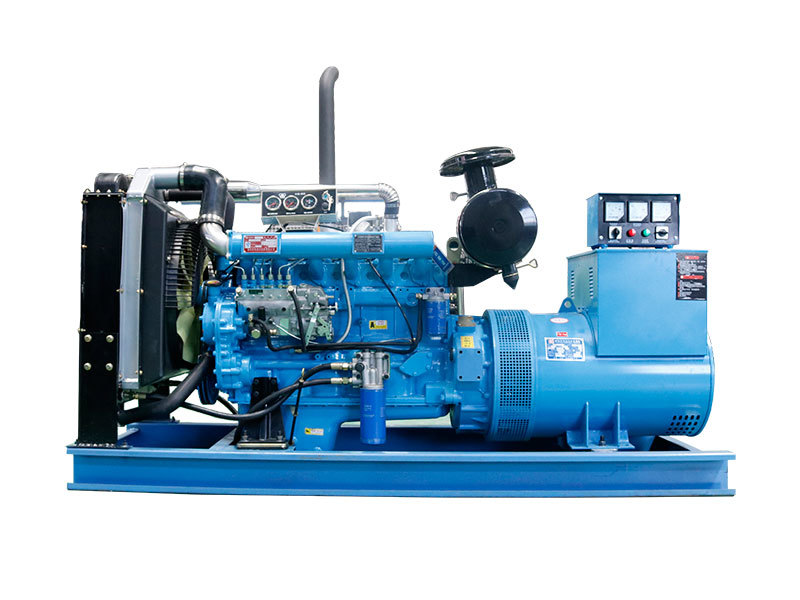

In the realm of reliable power, a generator set stands as a steadfast guardian against outages, a critical asset for homes, businesses, and vital services. Yet, like any complex machinery, its continued performance and, more importantly, its lifespan, aren't guaranteed simply by its initial quality. The key to ensuring your generator set serves you faithfully for years, potentially decades, lies not just in its design but profoundly in the care it receives. This care isn't merely routine; it involves understanding and applying specific, often overlooked, practices – what many might call secrets – that collectively unlock the full potential for longevity. We're talking about moving beyond the basic checks to a proactive, informed approach that tackles wear and tear before it becomes a catastrophic failure. Have you ever wondered why some generator sets seem to run forever with minimal fuss, while others falter prematurely? Often, the difference boils down to the 'how' and 'when' of their maintenance. It's not just about fixing things when they break; it's about preventing them from breaking in the first place. This article delves into these 'top secrets,' revealing the essential strategies that can significantly extend the operational life of your generator set, ensuring it's ready when you need it most. We'll explore the critical linkages between consistent maintenance actions and the ultimate longevity you can expect, providing actionable insights drawn from experience and industry best practices. Understanding these principles is the first step towards securing your power future.

Understanding the Crucial Link Between Maintenance and Unlocking Generator Set Longevity

Frankly speaking, the connection between diligent maintenance and the lifespan of your generator set isn't a secret in itself, but the depth of its impact and the specifics involved often remain hidden in plain sight for many operators. Longevity in mechanical equipment, especially something as demanding as a generator set, isn't accidental. It's a direct outcome of mitigating the factors that cause degradation and failure: friction, heat, corrosion, contamination, and stress. Regular, thorough maintenance acts as a shield against these forces. Think of it this way: every time your generator runs, components interact under stress. Engine parts move, electrical connections handle load, and cooling systems manage heat. Without proper lubrication, cooling, and calibration, this stress accelerates wear. Oil breaks down, filters clog, connections loosen, and cooling efficiency drops, leading to increased temperatures and strain on components. Over time, this accumulated wear reduces efficiency, increases the likelihood of breakdowns, and fundamentally shortens the operational life of the unit. The 'secret' here is recognizing that maintenance isn't just a cost; it's an investment in future reliability and extended asset life. It's about proactively addressing minor issues before they cascade into major, expensive repairs or necessitate premature replacement. We've seen countless examples where neglected maintenance has slashed a generator's expected lifespan by half or more. Conversely, units that receive consistent, high-quality care perform reliably for years beyond their typical warranty period. Unlocking longevity truly begins with a deep appreciation for how every maintenance task contributes to preserving the integrity and function of the entire system. It requires a shift from a reactive 'fix-it-when-it-fails' mindset to a proactive 'prevent-it-from-failing' philosophy, directly aligning with the core theme of revealing top generator set maintenance secrets for longevity.

The Unseen Cumulative Effects of Neglect

It's worth noting that many operators might perform some basic checks, like topping up fuel, but overlook the less obvious, cumulative effects of neglecting other areas. For instance, ignoring the quality and level of coolant can lead to overheating, which stresses engine components like pistons, cylinders, and gaskets, causing premature wear or even failure. Similarly, neglecting air filter replacement allows dirt and debris into the combustion chamber, accelerating piston ring and cylinder liner wear. Poor battery maintenance, often seen as minor, can prevent the generator from starting at all when needed, rendering it useless and putting undue strain on the starter motor and charging system. These aren't one-off failures but a gradual erosion of the generator's health, chipping away at its potential longevity piece by piece. The 'secret' lies in understanding that every part of the generator set is interconnected, and the health of the whole depends on the health of its individual components. Comprehensive maintenance addresses these potential points of failure systematically. This includes not just fluids and filters but also electrical connections, exhaust systems, fuel storage, and the control panel. Each check, each replacement, each calibration is a small but significant step towards preserving the generator's operational integrity and extending its life. It’s about preventing the domino effect where one small failure leads to a larger, more critical one. This holistic view is fundamental to unlocking the true longevity potential of your generator set through effective maintenance.

Revealing the Top Maintenance 'Secrets' for Unlocking Generator Set Longevity

Now, let's peel back the layers and reveal some of the top generator set maintenance 'secrets' that contribute significantly to unlocking their longevity. These aren't necessarily hidden, guarded industry secrets, but rather practices that are either commonly overlooked, misunderstood, or underestimated in their importance. One crucial secret is the absolute necessity of **using the correct fluids and filters, and changing them strictly according to the manufacturer's schedule, or even more frequently based on operating conditions.** Many operators might use generic oil or filters, or stretch change intervals to save money. However, modern engines are built with tight tolerances and specific lubrication and filtration requirements. Using the wrong type or contaminated fluids, or clogged filters, dramatically increases wear on critical components. High-quality oil, fuel, and coolant designed for your specific generator model are paramount. Another vital secret lies in **regular and thorough fuel system maintenance.** Fuel can degrade over time, especially if stored, leading to sediment, microbial growth, and water contamination. This contaminated fuel can clog filters, damage injection systems, and cause poor engine performance or outright failure. Regularly checking fuel quality, draining water separators, and treating stored fuel are non-negotiable for longevity, particularly for standby units that sit idle for long periods. Interestingly enough, **proper battery maintenance is often overlooked but is absolutely critical.** A weak battery is the single most common reason a generator fails to start. Checking terminals for corrosion, ensuring proper electrolyte levels (if applicable), and testing the battery's charge and health regularly can prevent frustrating failures and extend the life of the entire starting system. These seemingly simple steps are foundational to ensuring your generator is reliable today and remains so for years to come, embodying the essence of revealing maintenance secrets for enhanced generator longevity.

Going Beyond the Basics: Advanced Maintenance Practices

Beyond the essential fluids, filters, and fuel, some more advanced practices serve as powerful 'secrets' for extending generator set longevity. **Regularly exercising the generator under load** is one such practice. Running a generator regularly, ideally at least monthly and under a significant portion of its rated load, achieves several things: it circulates fluids, keeps seals lubricated, burns off moisture and carbon deposits from the engine, and verifies that the entire system – including the fuel supply, cooling system, and electrical output – is functioning correctly. Running without a load (no-load testing) isn't sufficient for shedding carbon or fully testing the system under operating conditions. Another secret is **performing regular load bank testing.** This involves connecting the generator to a device that draws a controlled electrical load, allowing technicians to test the generator's performance at various load levels, including full capacity. This reveals potential issues like poor voltage regulation, inadequate cooling under load, or engine weakness that might not be apparent during a simple start-up test. It's a definitive way to ensure the generator will perform as expected during a real outage. Furthermore, **implementing vibration analysis and thermal imaging** during inspections can reveal potential problems like loose components, bearing wear, or electrical hot spots before they become critical failures. These predictive maintenance techniques are less common for smaller generators but are powerful tools for maximizing longevity in larger or mission-critical units. Frankly speaking, embracing these more advanced techniques moves maintenance from reactive to predictive, allowing for timely interventions that prevent costly damage and significantly extend operational life.

The Strategic Importance of Proactive Checks in Unlocking Generator Set Life

The consistent theme throughout unlocking generator set longevity through top maintenance is the absolute necessity of proactive checks and inspections. Waiting for a problem to manifest is inherently reactive and often means that significant, potentially irreversible, wear or damage has already occurred. A proactive approach, built on a structured schedule of checks, allows you to identify minor issues early, often when they can be easily and inexpensively corrected. This isn't just about preventing breakdowns; it's fundamentally about preserving the original condition and efficiency of the machinery for as long as possible. Consider the cooling system: a proactive check might reveal a low coolant level or a minor leak in a hose clamp. Addressing this immediately prevents potential overheating, which, if left unchecked, can warp cylinder heads or seize an engine – a catastrophic longevity-ending event. Similarly, a proactive inspection of the exhaust system might reveal rust or loose connections. Repairing this prevents exhaust leaks, which can be dangerous (carbon monoxide) and indicate excessive back pressure stressing the engine. Electrical system checks, often involving testing voltage output, frequency, and inspecting wiring for signs of wear or corrosion, are also vital. A loose or corroded connection can create resistance, generate heat, and potentially lead to insulation breakdown or equipment damage. These aren't 'secrets' in terms of being unknown, but the 'secret' is in the discipline of performing them regularly and thoroughly, interpreting the findings correctly, and acting upon them promptly. Many experts agree that a well-structured proactive maintenance schedule is the single most effective strategy for maximizing generator set reliability and unlocking its full potential lifespan. It’s the difference between hoping your generator works when you need it and knowing that it will.

Developing and Adhering to a Customized Maintenance Schedule

A critical part of proactive maintenance, and a secret to its effectiveness in boosting longevity, is developing and rigorously adhering to a maintenance schedule tailored to your specific generator set model, its operating environment, and how it's used (standby vs. prime power). Manufacturer recommendations provide a baseline, but factors like extreme temperatures, dusty or corrosive atmospheres, or frequent short runs might necessitate more frequent servicing. For instance, a generator in a coastal environment might require more frequent checks for corrosion on electrical connections and the enclosure. A unit in a dusty agricultural setting will need more frequent air filter changes. The schedule should detail daily, weekly, monthly, quarterly, semi-annual, and annual checks and tasks. Daily or weekly checks might include visual inspections, checking fluid levels (oil, coolant, fuel), and ensuring the area around the generator is clear. Monthly checks could involve exercising the unit and checking battery voltage. Annual checks are typically more comprehensive, involving fluid and filter changes, detailed inspections of engine and electrical components, belt checks, hose inspections, and perhaps valve adjustments or fuel injector servicing as recommended by the manufacturer. The real 'secret' here isn't just having a schedule, but the discipline to follow it consistently. It requires commitment and resources, but the payoff in terms of reliable performance and extended longevity far outweighs the investment. It’s about creating a routine that becomes second nature, ensuring that no critical check is missed, thus proactively safeguarding the generator's future performance and lifespan.

Avoiding Common Pitfalls: More Secrets to Generator Longevity Revealed

Beyond the positive steps of performing maintenance, avoiding common pitfalls is equally crucial for unlocking generator set longevity. These pitfalls often involve seemingly minor oversights or attempts to cut corners that end up costing far more in the long run. One significant pitfall is **improper storage of fuel.** Diesel fuel, commonly used in generator sets, can degrade, collect water through condensation, and support microbial growth (diesel bug) over time, especially if left untreated in tanks. Using contaminated fuel is a leading cause of fuel system damage, including injectors and pumps, which are expensive to repair or replace and directly impact engine health and longevity. Storing fuel properly, using fuel stabilizers or biocides, and regularly inspecting and cleaning fuel tanks are vital secrets to avoiding this. Another pitfall is **overlooking the importance of the generator's environment.** Is it properly ventilated? Is it protected from extreme weather? Is the area around it clear of debris or combustible materials? Proper ventilation is essential to prevent overheating, which stresses the engine and alternator. Protection from the elements prevents corrosion and damage to components. Maintaining a clean environment minimizes the risk of dirt ingress into the air intake or cooling system. Interestingly enough, **failure to properly load the generator** when it runs is another common issue, especially for standby units. As mentioned, running the generator under insufficient load (light loading) can lead to 'wet stacking,' where unburned fuel and soot accumulate in the exhaust system. This reduces engine efficiency, increases wear, and can cause long-term damage. Ensuring the generator is exercised with an adequate load is a critical secret to maintaining engine health and longevity. Avoiding these common traps is as important as performing the recommended maintenance tasks; they are the flip side of the coin when it comes to securing the long-term performance of your generator set.

Addressing Longevity Challenges with Expert Generator Set Maintenance

While understanding the top generator set maintenance secrets for unlocking longevity is key, effectively implementing them can sometimes require expertise beyond basic owner capabilities. Modern generator sets, especially larger or more complex industrial units, involve sophisticated electrical systems, advanced engine management controls, and precise mechanical components. Diagnosing subtle issues, performing intricate adjustments like valve clearances, or troubleshooting control panel errors often requires specialized knowledge and tools. This is where partnering with experienced maintenance professionals becomes invaluable. We, as a company specializing in generator sets, understand these complexities deeply. Our services are designed to directly address the challenges of achieving long-term generator longevity by applying these very 'secrets' and best practices systematically. We provide comprehensive maintenance plans that go beyond routine fluid changes, incorporating detailed inspections, load bank testing, electrical system analysis, and predictive maintenance techniques like thermal imaging or vibration analysis where appropriate. Our technicians are trained to identify early warning signs of potential failure that a less experienced eye might miss. They understand the specific requirements of different generator brands and models and use the correct parts and fluids. Frankly speaking, while it's beneficial for owners to understand the principles of generator maintenance, knowing when to call in expert help is itself a vital secret to ensuring maintenance is performed correctly and effectively, maximizing the unit's lifespan and reliability. Our role is to provide that expert layer of care, ensuring your investment delivers power reliably for its full potential life cycle.

The Value of Professional Maintenance Planning and Execution

The value of professional maintenance planning and execution cannot be overstated when it comes to unlocking maximum generator set longevity. A professional service provider doesn't just perform tasks; they implement a strategic plan based on the unit's age, history, operating hours, and environmental conditions. They keep detailed records of all maintenance performed, creating a maintenance history that is invaluable for tracking the unit's health and predicting future needs. This level of structured care ensures that no critical maintenance interval is missed and that potential issues are identified and addressed proactively. For example, a professional service might notice a slight increase in oil consumption or a subtle change in exhaust color during a routine check, indicating a potential issue that can be investigated and corrected before it leads to serious engine damage. They can also perform critical checks like coolant system pressure testing, fuel injector testing, or alternator bearing checks that are beyond the scope of typical user maintenance. By entrusting your generator set's care to experts, you're not just buying maintenance services; you're investing in peace of mind and the assurance that every measure is being taken to extend its life and ensure its readiness. This professional layer of care is often the true 'secret' that differentiates generator sets that fail prematurely from those that deliver reliable power for decades, fully realizing the potential described in unlocking longevity through top generator set maintenance secrets.

Integrating Technology and Data for Enhanced Generator Set Longevity

In the modern era, leveraging technology and data has become an increasingly significant factor in unlocking and extending generator set longevity. Many contemporary generator sets are equipped with sophisticated control systems that can monitor various parameters in real-time, such as engine temperature, oil pressure, fuel levels, battery voltage, run hours, and even vibration levels. These systems can log data and alert operators or maintenance personnel to conditions that deviate from the norm. The 'secret' here is not just having this technology, but effectively utilizing the data it provides. Analyzing trends in operational data can offer crucial insights into the generator's health and predict potential issues before they cause failure. For example, a gradual increase in coolant temperature under the same load conditions might indicate a cooling system blockage or reduced efficiency, prompting an inspection before overheating occurs. Similarly, monitoring battery voltage trends can predict when a battery is nearing the end of its life, allowing for proactive replacement rather than discovering a dead battery during an emergency. Remote monitoring systems take this a step further, allowing professionals to track generator status and performance from a distance, enabling faster response to alerts and scheduled maintenance based on actual run hours and conditions rather than just calendar time. This data-driven approach to maintenance allows for more targeted and effective interventions, moving beyond traditional time-based schedules to condition-based maintenance. It’s a powerful tool in the arsenal of top maintenance secrets for maximizing generator set longevity, ensuring care is delivered precisely when and where it’s needed most.

The Role of Quality Parts and Consistent Attention in Extending Generator Set Life

When discussing the top maintenance secrets for unlocking generator set longevity, two intertwined elements stand out: the use of quality parts and the commitment to consistent, attentive care. It might be tempting to use cheaper, non-OEM (Original Equipment Manufacturer) parts or generic fluids to save on maintenance costs. However, this is a classic example of being penny-wise and pound-foolish. Quality parts are designed and manufactured to meet the precise specifications and tolerances of your specific generator model. Using substandard parts, such as filters that don't effectively remove contaminants or belts that wear prematurely, can lead to increased wear and stress on other components, ultimately reducing the generator's lifespan. Similarly, while seemingly small, consistently paying attention to the generator's performance and condition is a crucial secret. This means not just performing scheduled tasks but also being observant during operation or during brief checks. Do you hear any unusual noises? Are there any strange smells? Are there any visible leaks or signs of wear? These observations, even by a non-expert, can be the earliest indicators of a brewing problem. Reporting such observations to maintenance personnel allows for investigation and correction before a minor issue escalates. The 'secret' is in fostering a culture of attention and care around the generator set. It's not just a piece of equipment; it's an asset that requires consistent oversight. Combining the use of high-quality, manufacturer-recommended parts with this level of attentive observation and care forms a powerful strategy for preserving your generator set's health and ensuring it provides reliable power for its maximum potential lifespan. Have you ever experienced how quickly a small, unnoticed issue can become a major problem? Consistent attention helps prevent that cascade effect.

In conclusion, unlocking the full longevity of your generator set isn't a matter of luck; it's the direct result of implementing a comprehensive, proactive, and informed maintenance strategy. The 'top secrets' revealed here – from understanding the critical link between maintenance and lifespan, to the use of correct fluids and filters, diligent fuel and battery care, regular load testing, avoiding common pitfalls, leveraging expert services, and integrating technology – all converge on a single principle: consistent, quality care prevents premature wear and failure. By embracing these practices, you move beyond simply owning a generator to actively ensuring its sustained reliability and maximizing your investment. The journey to a longer-lasting, more dependable generator set is paved with proactive checks, expert insights, and a commitment to not cutting corners on care. Ultimately, a well-maintained generator set is a reliable guardian of power, ready to perform when needed, for many years to come, truly embodying the concept of unlocking longevity through top generator set maintenance secrets.

For more detailed information, please visit our official website: Generator Set Maintenance