In the demanding world of industry, uninterrupted power is not a luxury; it's a fundamental necessity. From sprawling manufacturing plants to critical data centers and healthcare facilities, operations hinge on a constant supply of electricity. Any interruption, no matter how brief, can lead to significant financial losses, safety hazards, data corruption, and even reputational damage. This is where **industrial generator sets** step in, serving as the silent guardians against power outages, ensuring that vital processes continue seamlessly. Understanding the intricacies of these powerful machines is crucial for any business that cannot afford downtime. They represent a significant investment, yes, but one that pays dividends by safeguarding productivity, protecting assets, and maintaining operational integrity when the unexpected occurs. Frankly speaking, relying solely on the grid in an industrial environment is a gamble few can afford to take, making these generator sets an indispensable part of modern infrastructure planning.

Understanding the Critical Role of Industrial Generator Sets

The necessity of robust backup power becomes starkly clear when you consider the potential fallout from even a minor grid failure in an industrial setting. Imagine a chemical plant where a power dip halts a critical reaction, potentially ruining an entire batch and creating hazardous conditions. Or a data center where a sudden outage could lead to irreversible data loss and hours or days of system recovery. These scenarios highlight why industrial generator sets are more than just backup equipment; they are essential components of operational resilience. They provide the crucial bridge between grid power loss and the resumption of normal operations, often automatically engaging within seconds. This ability to quickly and reliably take over the power supply is what prevents cascading failures and protects complex industrial systems. It's worth noting that the scale and complexity of power demands in industry require generator sets designed specifically for heavy-duty, continuous or near-continuous operation, unlike smaller commercial or residential units. Their robust construction, advanced control systems, and capacity to handle large, fluctuating loads are paramount to meeting industrial requirements.

Different sectors within the industrial landscape have unique power needs, further emphasizing the tailored solutions that industrial generator sets provide. For a manufacturing facility with heavy machinery, the generator must handle significant startup surges. A hospital requires absolutely reliable power for life support systems and medical equipment, often necessitating redundant generator setups. Data centers, critical for the digital economy, need generators capable of powering massive cooling systems and servers without interruption. The mining sector, often operating in remote locations with unstable grid access, relies heavily on **diesel generator sets for industrial use** as primary power sources. Each of these scenarios demands a specific type of generator set configuration, fuel source, and control system integration. Understanding these varied applications helps illuminate why selecting the right generator isn't a one-size-fits-all process but requires careful assessment of the specific operational context, load profile, and regulatory environment the system will operate within. Have you ever wondered how hospitals maintain critical care during widespread blackouts? It's the reliability of their industrial generator sets that makes it possible.

Key Considerations When Choosing Industrial Generator Sets

Selecting the appropriate industrial generator set is a complex decision with significant implications for reliability and cost-effectiveness. One of the most critical first steps is accurately determining the required power capacity. This involves a thorough load study, accounting for both current and future power needs, including steady-state loads, transient loads (like motor startups), and potential expansion. Undersizing a generator means it won't handle the required load, potentially leading to system failures when power is needed most. Oversizing, on the other hand, results in unnecessary capital expenditure and potentially inefficient operation, especially if the generator frequently runs below its optimal load. Many experts agree that consulting with power generation specialists for a detailed load analysis is invaluable. They can help calculate peak demand, consider power factor, and assess the impact of non-linear loads, ensuring the chosen generator is perfectly matched to the operational requirements, providing sufficient power reserve without excessive capacity.

Another major factor is the choice of fuel type. Diesel generators have historically been the standard for industrial backup power due to their reliability, durability, and ease of maintenance. Diesel fuel is energy-dense and relatively simple to store, making it suitable for long-duration outages. However, diesel generators produce emissions and require proper ventilation and fuel management. Natural gas generators are becoming increasingly popular, especially where a reliable natural gas line is available. They typically have lower emissions and can be more cost-effective to run for extended periods, assuming stable gas prices. Propane is another option, often used for smaller industrial applications or in locations where natural gas isn't available, offering good storability but potentially higher fuel costs. The decision between these fuels for **industrial generator sets** depends on local availability, fuel costs, environmental regulations, runtime requirements, and site-specific constraints. Interestingly enough, some larger industrial facilities are exploring dual-fuel options to enhance flexibility and reliability.

Beyond size and fuel, numerous technical specifications and features differentiate industrial generator sets and must be considered based on the application. The type of transfer switch (manual or automatic) is crucial for determining how quickly the generator takes over after a grid failure. Automatic transfer switches are essential for applications requiring immediate, uninterrupted power, such as data centers or critical manufacturing lines. For facilities with fluctuating or growing power needs, generators with paralleling capabilities allow multiple units to work together, providing scalability and redundancy. Noise levels can be a significant concern, particularly in urban or suburban industrial areas, making sound-attenuated enclosures a necessary feature. Furthermore, modern industrial generators come with sophisticated control systems and remote monitoring capabilities, allowing operators to track performance, fuel levels, and maintenance needs from a distance. Ensuring compliance with relevant local, national, and industry-specific standards (like NFPA 110 for emergency and standby power systems) is non-negotiable when selecting **large capacity generators for businesses** operating in regulated environments.

Installation and Maintenance: Ensuring Long-Term Reliability

Acquiring the right industrial generator set is only the first step; proper installation is equally critical to ensure its reliable performance over its lifespan. Industrial generators are heavy, complex pieces of machinery requiring specific site preparation. This includes preparing a level, load-bearing foundation, ensuring adequate ventilation for cooling and exhaust, and planning for fuel storage and delivery. The electrical connection to the facility's power distribution system must be handled by qualified professionals familiar with high-capacity wiring and transfer switch integration. Safety is paramount during installation, involving adherence to strict electrical codes and safety standards. In my experience, cutting corners during installation is a recipe for future problems, potentially leading to system malfunctions or even dangerous situations during an actual power outage. A correctly installed system ensures the generator operates efficiently, safely, and is truly ready to provide power the moment it's needed, integrating seamlessly with the existing infrastructure.

Once installed, a robust preventative maintenance program is absolutely essential for the long-term reliability of **industrial generator sets**. Unlike equipment that runs continuously, standby generators may sit idle for extended periods, but this doesn't mean they don't require attention. Stored fuel can degrade, batteries can lose charge, and components can seize up if not regularly inspected and tested. A typical maintenance schedule involves routine checks of fluid levels (oil, coolant), battery health, filter replacement (air, fuel, oil), and a crucial step: regular load bank testing. Load bank testing involves running the generator at a significant percentage of its capacity using an artificial load, ensuring it can perform under real-world conditions and burning off deposits that can accumulate during light-load exercise runs. This proactive approach identifies potential issues before they cause a failure during an actual emergency. For **standby power solutions for factories**, consistent maintenance isn't just about preventing breakdowns; it's about guaranteeing readiness, which is the entire point of having a backup system in the first place. Ignoring maintenance is like having a fire extinguisher you never check – you hope it works, but you can't be sure.

Our Solutions for Your Industrial Power Needs

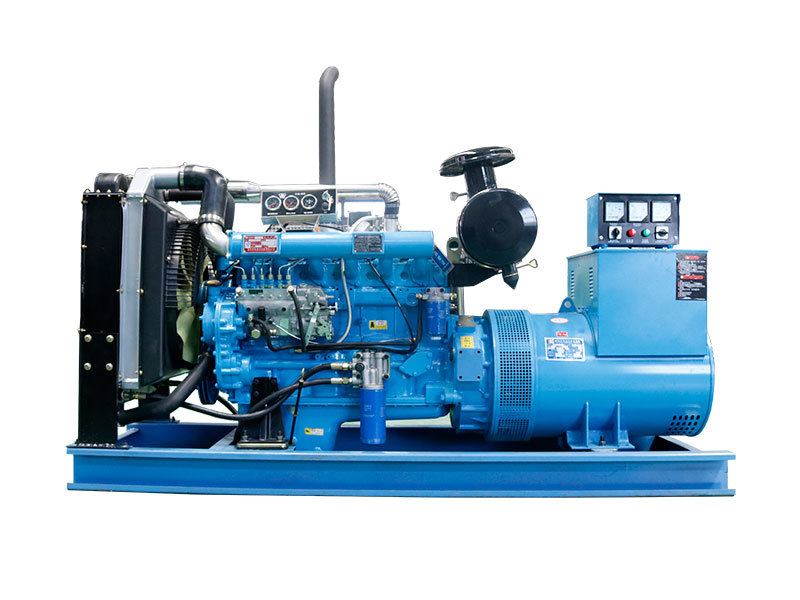

Understanding the complexities of selecting, installing, and maintaining reliable power systems, our company specializes in providing comprehensive solutions tailored to the unique demands of industrial operations. We offer a wide range of **industrial generator sets**, from various fuel types and capacities to meet diverse requirements, whether you need primary power in a remote location or robust backup for a critical facility. Our expertise extends beyond simply selling equipment; we partner with our clients to assess their specific needs, conduct detailed load analyses, and recommend the optimal generator configuration. We understand the critical nature of uninterrupted power and the significant investment involved. Our approach is focused on delivering not just a product, but a complete power solution that ensures reliability, efficiency, and peace of mind, safeguarding your operations against the uncertainties of the grid.

We pride ourselves on offering high-quality, durable generator sets built for the rigorous demands of industrial environments. Furthermore, our commitment doesn't end with the sale. We provide professional installation support, ensuring your generator is set up correctly and safely integrated into your existing system. Crucially, we offer comprehensive maintenance programs designed to keep your **industrial generator sets** in peak operating condition, ready to perform when you need them most. Our service plans include regular inspections, preventative maintenance, and load bank testing performed by certified technicians, ensuring that your investment delivers reliable backup power year after year. Choosing our company means gaining a partner dedicated to your operational continuity, providing the reliable power infrastructure necessary for success in today's demanding industrial landscape.

In conclusion, industrial generator sets are indispensable assets for businesses where power reliability is paramount. Their selection requires careful consideration of power needs, fuel type, and specific features, while proper installation and diligent preventative maintenance are key to ensuring they deliver reliable performance when called upon. Investing in a high-quality, well-maintained generator set is an investment in operational resilience, protecting against costly downtime and potential hazards. With the right planning and partnership, you can ensure your industrial operations remain powered, productive, and secure, regardless of external grid conditions. To be honest, the peace of mind that comes with knowing your critical systems are protected by a reliable backup power source is immeasurable for any industrial leader.

For more detailed information, please visit our official website: Industrial Generator Sets