The simple answer to the question "Does a genset have an alternator?" is a resounding yes. An alternator is absolutely critical to the operation of a generator set, often shortened to genset. It's the heart of the electricity-generating process. In fact, without an alternator, a genset is just an engine and a frame; it wouldn't be able to fulfill its primary purpose: to provide electrical power.

Understanding the Genset and its Components

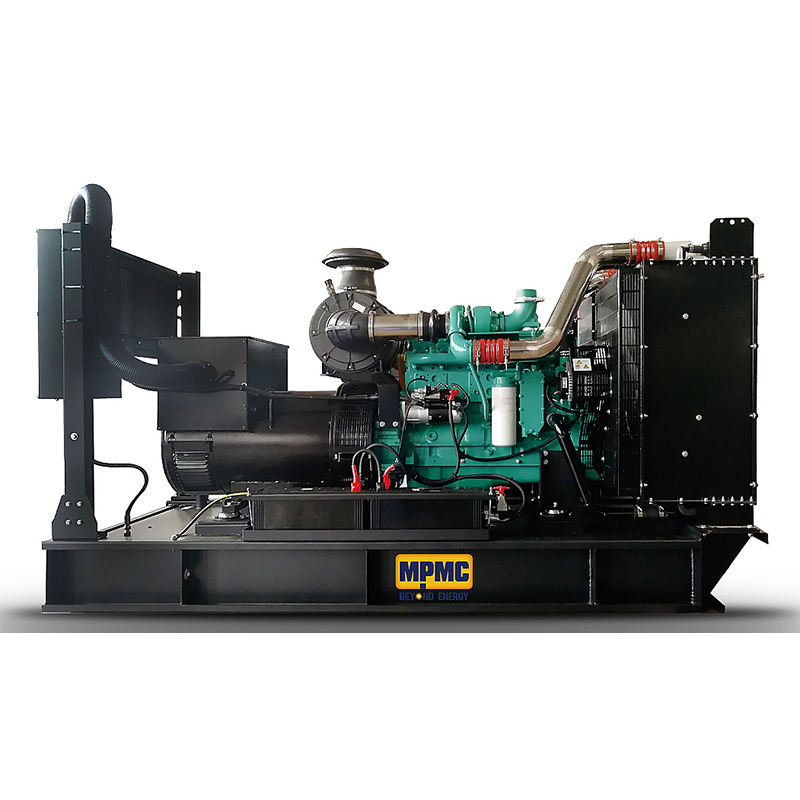

To fully appreciate why an alternator is essential, it’s helpful to understand the basic makeup of a genset. A genset is essentially a self-contained system that converts mechanical energy into electrical energy. The core components typically include an engine (which provides the mechanical energy), an alternator (which converts that mechanical energy into electrical energy), a fuel system, a cooling system, a lubrication system, and a control panel. The engine, usually powered by diesel, gasoline, natural gas, or propane, turns a shaft connected to the alternator. The alternator then uses the principles of electromagnetic induction to generate alternating current (AC) electricity.

The Role of the Alternator

The alternator's job is to take the mechanical energy supplied by the engine and transform it into usable electrical energy. It does this by exploiting the relationship between magnetism and electricity. Inside the alternator are coils of wire and magnets. As the engine spins the alternator's rotor (the rotating part), these coils of wire move through a magnetic field. This movement causes electrons in the wire to flow, generating an electric current. The alternating current (AC) produced is then regulated and sent to the genset's output terminals for use in powering various electrical devices and systems. The effectiveness and efficiency of the alternator directly impacts the overall performance and reliability of the genset. What happens if the alternator malfunctions or fails completely? The genset simply stops producing electricity, rendering it useless until the alternator is repaired or replaced.

How Alternators Work: A Closer Look

Let's delve a little deeper into the inner workings of an alternator. The key to understanding its operation lies in the principle of electromagnetic induction, discovered by Michael Faraday. Essentially, when a conductor (like a wire) moves through a magnetic field, a voltage is induced in the conductor, causing electrons to flow – this is electricity! An alternator typically has two main parts: the stator and the rotor. The stator is the stationary part, and it contains the coils of wire where the electricity is generated. The rotor, as mentioned, is the rotating part, and it contains magnets (or electromagnets) that create the magnetic field. As the rotor spins, the magnetic field sweeps across the stator coils, inducing a voltage and thus generating an electric current. This is a continuous process as long as the engine is running and turning the rotor.

Types of Alternators Used in Gensets

While the fundamental principle remains the same, alternators used in gensets can vary in design and construction. Some common types include synchronous alternators and asynchronous alternators (also known as induction alternators). Synchronous alternators are more prevalent in gensets due to their ability to maintain a constant output frequency regardless of load variations. They also offer better voltage regulation and are generally more efficient. Asynchronous alternators, while simpler in design, are less efficient and have poorer voltage regulation, making them less suitable for applications requiring stable and consistent power output. The choice of alternator type depends on the specific application and the desired performance characteristics of the genset.

Practical Examples and Applications

The presence of an alternator makes gensets incredibly versatile and applicable across a wide range of scenarios. Consider a construction site where access to the electrical grid is limited or non-existent. A genset equipped with a robust alternator can provide the necessary power for tools, lighting, and even temporary office structures. Hospitals rely heavily on gensets with reliable alternators to provide backup power during grid outages, ensuring that critical medical equipment and life-support systems continue to function uninterrupted. Data centers, telecommunication facilities, and other businesses that require continuous power also depend on gensets with high-quality alternators to safeguard their operations. Even residential homes can benefit from gensets during emergencies, providing power for essential appliances and lighting. The common thread in all these examples is the vital role of the alternator in converting mechanical energy into the electrical power that keeps things running.

Factors Affecting Alternator Performance

Several factors can influence the performance and lifespan of an alternator in a genset. Proper maintenance is paramount. Regular inspections, cleaning, and lubrication can prevent premature wear and tear. Overloading the genset beyond its rated capacity can strain the alternator, leading to overheating and potential damage. Environmental factors, such as excessive dust, humidity, or extreme temperatures, can also negatively impact alternator performance. Selecting the right size and type of alternator for the intended application is crucial. An undersized alternator will struggle to meet the load demands, while an oversized alternator may operate inefficiently. It's also important to ensure that the alternator is properly grounded to prevent electrical hazards and ensure optimal performance. Have you ever wondered how the operating environment impacts the long-term reliability of a genset alternator?

Maintenance and Troubleshooting

Maintaining the alternator is crucial for the genset's overall health. Regular checks should include inspecting the windings for damage, verifying the condition of the brushes (in some types of alternators), and ensuring proper ventilation to prevent overheating. Signs of alternator trouble can include fluctuating voltage output, unusual noises, or a complete failure to generate electricity. Troubleshooting can involve checking the wiring connections, testing the rotor and stator windings for continuity, and inspecting the voltage regulator. In some cases, professional servicing may be required to diagnose and repair complex alternator issues. Ignoring these warning signs can lead to more significant and costly problems down the line. Remember that preventive maintenance is always more cost-effective than reactive repairs.

The Future of Genset Alternators

The technology behind genset alternators continues to evolve. Manufacturers are constantly striving to improve efficiency, reduce size and weight, and enhance reliability. Developments in materials science are leading to the creation of alternators that can withstand higher temperatures and operate more efficiently. Digital control systems are becoming increasingly sophisticated, allowing for more precise voltage regulation and improved diagnostics. The integration of renewable energy sources, such as solar and wind, with gensets is also driving innovation in alternator design. As the demand for reliable and efficient power generation continues to grow, we can expect to see even more advancements in genset alternator technology.

Conclusion

Therefore, to reiterate, the answer to "Does a genset have an alternator?" is an unequivocal yes. The alternator is not merely an accessory but an absolutely integral and indispensable component. Without it, the genset simply cannot perform its core function of generating electricity. Understanding the alternator's role, how it works, and how to maintain it is crucial for anyone who relies on gensets for power, whether in critical applications like hospitals and data centers, or in more common scenarios like construction sites and homes during emergencies. The alternator is truly the unsung hero of the genset, quietly and reliably converting mechanical energy into the electricity that powers our world.