The critical role of a power plant equipment supplier cannot be overstated in the efficient and reliable operation of any power generation facility. These suppliers are the backbone of the energy industry, providing the essential components and systems that allow us to keep the lights on and power our modern world. Without a dependable source for high-quality turbines, generators, boilers, control systems, and auxiliary equipment, power plants would struggle to maintain consistent output, face frequent downtime, and ultimately fail to meet the ever-growing demand for electricity. But what truly distinguishes a good supplier from a merely adequate one? Is it simply price, or are there other crucial factors to consider when selecting a partner for such vital infrastructure?

The Breadth of Power Plant Equipment

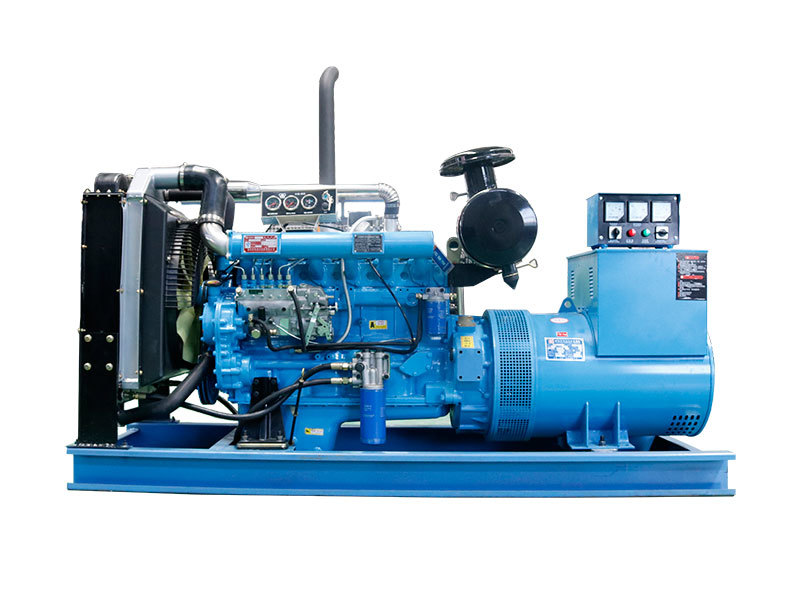

The term "power plant equipment" encompasses a vast array of machinery and systems, each playing a vital role in the overall energy conversion process. From the massive turbines that spin under the force of steam, gas, or water, to the complex generators that convert mechanical energy into electrical power, the equipment list is extensive and demanding. Boilers, responsible for generating the steam to drive turbines, are subjected to extreme temperatures and pressures, requiring robust design and materials. Control systems, the brains of the operation, ensure that all components function in harmony, optimizing efficiency and preventing catastrophic failures. Beyond these core components, auxiliary equipment such as pumps, heat exchangers, and cooling towers are equally essential for maintaining a stable and efficient operating environment. Therefore, a comprehensive supplier must offer not only a broad range of equipment but also the expertise to advise on the selection, integration, and maintenance of these systems.

Key Considerations When Choosing a Supplier

Selecting a power plant equipment supplier is a strategic decision with long-term implications. Price is certainly a factor, but it shouldn't be the sole determinant. The quality and reliability of the equipment are paramount. Investing in cheaper, lower-quality components may seem appealing initially, but it can lead to higher maintenance costs, increased downtime, and potentially catastrophic failures down the line. Therefore, a supplier's reputation for providing durable, high-performance equipment is crucial. What about their experience in the power generation sector? A supplier with a proven track record of successful projects is better positioned to understand the unique challenges and requirements of a power plant environment. Moreover, their ability to provide comprehensive after-sales support, including installation, commissioning, maintenance, and spare parts availability, is essential for ensuring the long-term viability of the equipment.

The Importance of Quality and Reliability

In the demanding world of power generation, quality and reliability are not just desirable attributes; they are absolute necessities. Power plants operate around the clock, often under extreme conditions, and any equipment failure can have significant consequences, ranging from power outages and financial losses to safety hazards. Therefore, power plant equipment suppliers must adhere to the highest quality standards, employing rigorous testing and inspection procedures to ensure that their products meet or exceed industry benchmarks. This includes sourcing high-quality materials, employing skilled manufacturing techniques, and implementing robust quality control processes throughout the entire production cycle. Furthermore, suppliers should be able to provide comprehensive documentation and certifications to verify the quality and performance of their equipment. What testing procedures do they use to ensure their equipment can withstand the rigors of continuous operation?

After-Sales Service and Support

The relationship with a power plant equipment supplier doesn't end with the sale. In fact, it's just the beginning. Comprehensive after-sales service and support are essential for ensuring the long-term performance and reliability of the equipment. This includes providing expert installation and commissioning services to ensure that the equipment is properly installed and integrated into the existing power plant infrastructure. It also includes offering ongoing maintenance and repair services to address any issues that may arise during the equipment's operational life. Perhaps most importantly, a reliable supplier should maintain a readily available stock of spare parts to minimize downtime in the event of a breakdown. A supplier's commitment to after-sales support demonstrates their dedication to the long-term success of their customers and their willingness to partner with them throughout the entire lifecycle of the equipment.

Technological Advancements in Power Plant Equipment

The power generation industry is constantly evolving, driven by the need for greater efficiency, reduced emissions, and increased reliability. As a result, power plant equipment suppliers are continuously innovating and developing new technologies to meet these demands. For instance, advancements in turbine design have led to increased power output and improved efficiency. The integration of smart sensors and data analytics into control systems allows for real-time monitoring and optimization of plant performance. The development of advanced materials, such as high-temperature alloys, has enabled boilers to operate at higher temperatures and pressures, further enhancing efficiency. A forward-thinking supplier stays abreast of these technological advancements and incorporates them into their product offerings, providing power plants with the tools they need to stay competitive in a rapidly changing market. This continuous innovation ensures that the power generation industry can meet future energy demands while minimizing its environmental impact.

The Role of Customization and Engineering Solutions

While many power plant components are standardized, the specific requirements of each power plant can vary significantly depending on factors such as fuel source, operating conditions, and environmental regulations. Therefore, a valuable power plant equipment supplier should be able to offer customization and engineering solutions tailored to the unique needs of each project. This may involve modifying existing equipment designs to meet specific performance requirements, or developing completely new solutions to address novel challenges. A supplier with in-house engineering capabilities can work closely with power plant operators to understand their specific needs and develop solutions that optimize performance, efficiency, and reliability. This collaborative approach ensures that the equipment is perfectly suited to the application, maximizing its value and minimizing the risk of costly downtime. Do they offer on-site consultations and performance assessments to ensure the best fit for your plant’s needs?

The Future of Power Plant Equipment Suppliers

The future landscape of power plant equipment suppliers is set to be shaped by a multitude of factors, including the ongoing transition towards renewable energy sources, increasing demands for energy efficiency, and the ever-growing importance of environmental sustainability. Suppliers who adapt and innovate will be best positioned to thrive in this evolving environment. This includes developing equipment that is compatible with renewable energy sources such as solar and wind, offering solutions that reduce emissions and improve energy efficiency, and embracing sustainable manufacturing practices. Furthermore, the increasing adoption of digital technologies, such as artificial intelligence and machine learning, will create new opportunities for suppliers to optimize equipment performance and provide predictive maintenance services. By embracing these trends and investing in innovation, power plant equipment suppliers can play a crucial role in shaping a cleaner, more efficient, and more sustainable energy future. What strategies are they employing to support the integration of renewable energy sources?

Conclusion

In conclusion, the role of a power plant equipment supplier is undeniably pivotal in ensuring the reliable and efficient generation of electricity. Beyond simply providing equipment, these suppliers are integral partners in the power generation process. Choosing the right power plant equipment supplier requires careful consideration of factors such as equipment quality, reliability, after-sales service, and technological innovation. By partnering with a reputable and experienced power plant equipment supplier, power plants can ensure the long-term viability and performance of their operations, ultimately contributing to a more sustainable and reliable energy future.