In today's increasingly power-dependent world, generator sets have moved far beyond being simple backup solutions. They are now sophisticated pieces of technology, integral to ensuring business continuity, supporting critical infrastructure, and even enabling off-grid living. To be honest, the pace of innovation in generator technology has been quite remarkable in recent years. We’re no longer just talking about engines and alternators; we're delving into the realms of smart controls, advanced fuel systems, and environmentally conscious designs. For anyone relying on generator sets, whether for a small business, a large industrial facility, or even a household seeking reliable backup power, understanding these latest technologies isn't just beneficial, it's essential for making informed decisions and maximizing the value of your investment. The advancements are not merely incremental improvements; they represent a significant leap forward in performance, efficiency, and environmental responsibility. It's worth taking a closer look at what's driving this evolution and what these advancements mean for you.

Smart Generator Controls and Monitoring Systems

One of the most transformative advancements in generator set technology is the integration of smart controls and monitoring systems. Think about it – traditionally, managing a generator often involved manual checks, on-site inspections, and reactive maintenance. However, modern generators are increasingly equipped with sophisticated digital controllers and IoT (Internet of Things) connectivity. These systems allow for remote monitoring of vital parameters such as fuel levels, engine temperature, oil pressure, and output power. Furthermore, many systems now incorporate predictive maintenance capabilities, analyzing operational data to anticipate potential issues before they escalate into costly breakdowns. This proactive approach not only minimizes downtime but also optimizes maintenance schedules, extending the lifespan of the generator. User-friendly interfaces, often accessible via web portals or mobile apps, provide real-time insights and control, empowering users to manage their power systems with unprecedented ease and efficiency. Have you ever considered how much time and resources could be saved by remotely diagnosing and addressing a generator issue before it becomes a major problem? This shift towards intelligent management is redefining how we interact with and rely on generator sets.

Predictive Maintenance and Remote Diagnostics

Delving deeper into smart controls, predictive maintenance stands out as a game-changer. Instead of adhering to rigid, time-based maintenance schedules, predictive maintenance leverages data analytics and machine learning to assess the actual condition of generator components. Sensors embedded within the generator continuously monitor key performance indicators, feeding data back to sophisticated algorithms. These algorithms can then identify patterns and anomalies that indicate potential failures, often long before they become apparent through traditional inspections. This allows for targeted maintenance interventions, replacing components only when necessary, rather than prematurely or reactively. Remote diagnostics further enhances this capability, enabling technicians to remotely access generator data, diagnose issues, and even perform software updates without physically being on-site. In my experience, this has drastically reduced response times and minimized disruptions, especially for critical applications where downtime is simply not an option. Frankly speaking, the ability to foresee and prevent failures represents a significant step towards maximizing uptime and minimizing operational costs.

Advancements in Fuel Efficiency and Alternative Fuels

Fuel costs are a major operational expense for generator sets, and environmental concerns are increasingly pushing for cleaner energy solutions. Consequently, advancements in fuel efficiency and the exploration of alternative fuels are at the forefront of generator technology innovation. Modern generators are incorporating technologies like variable speed engines, which adjust engine speed based on the actual power demand, rather than running at a constant, often inefficient, speed. Lean-burn combustion technologies optimize the air-fuel mixture to maximize efficiency and reduce fuel consumption. Furthermore, there's a growing interest in and adoption of alternative fuels such as natural gas, propane, and even biodiesel. Natural gas generators, for instance, offer cleaner emissions compared to diesel, and propane can be a cost-effective and readily available fuel source in many regions. The exploration of biodiesel and other renewable fuels is also gaining momentum, driven by the desire for more sustainable power solutions. Why is this focus on fuel efficiency so critical? Simply put, it translates to lower operating costs, reduced environmental impact, and greater long-term sustainability for generator users. It's a win-win situation from both an economic and environmental perspective.

Variable Speed Generators and Lean-Burn Technology

To understand the impact of fuel efficiency technologies, consider variable speed generators in more detail. Traditional generators typically operate at a fixed speed, usually 1800 RPM for 60Hz systems, regardless of the load. This means that even when only a fraction of the generator's capacity is needed, the engine is still running at full speed, consuming fuel unnecessarily. Variable speed generators, on the other hand, utilize sophisticated controllers to adjust engine speed in direct proportion to the power demand. When the load is low, the engine speed reduces, significantly cutting down on fuel consumption and noise levels. As the load increases, the engine speed ramps up to meet the demand, ensuring optimal performance at all times. Lean-burn technology complements this by optimizing the combustion process itself. By carefully controlling the air-fuel mixture, these systems ensure more complete combustion, extracting maximum energy from each unit of fuel and minimizing unburned hydrocarbons and other pollutants. These combined technologies represent a significant leap in generator efficiency, making modern units far more economical and environmentally friendly than their predecessors. It’s quite impressive how much fuel savings can be achieved simply by optimizing engine speed and combustion.

Noise Reduction Technologies for Quieter Operation

Generator sets, especially larger diesel models, have historically been associated with significant noise pollution. However, advancements in noise reduction technologies are dramatically changing this perception. Modern generators are being designed with a focus on quieter operation, incorporating features like sound attenuation enclosures, advanced mufflers, and vibration dampening systems. Sound attenuation enclosures are essentially insulated containers that surround the generator, significantly reducing the amount of noise that escapes. Advanced mufflers are designed to effectively dampen exhaust noise across a wider frequency range. Vibration dampening mounts and materials minimize the transmission of vibrations from the engine and alternator to the surrounding structure, further reducing noise levels. These technologies are particularly crucial in residential areas, hospitals, and other noise-sensitive environments. Imagine the difference between a generator that roars like a truck engine and one that operates with a gentle hum. The latest noise reduction technologies are making generators far more acceptable and versatile for a wider range of applications. It's about making essential power sources less intrusive and more community-friendly.

Sound Attenuation Enclosures and Advanced Muffler Designs

Let’s take a closer look at sound attenuation enclosures. These enclosures are not just simple boxes; they are engineered systems designed to minimize noise transmission through multiple layers of insulation and sound-absorbing materials. The design often incorporates features like baffled air inlets and outlets to allow for engine cooling while blocking sound waves. The materials used are carefully selected for their sound absorption and insulation properties, often including combinations of foam, mineral wool, and steel. Advanced muffler designs go beyond basic noise reduction. Modern mufflers often employ multi-chamber designs and reactive or absorptive elements to target specific noise frequencies. Some even incorporate active noise cancellation technologies, which use microphones and speakers to generate anti-noise waves that effectively neutralize unwanted sounds. The combination of these enclosure and muffler technologies results in generator sets that are significantly quieter than previous generations, making them suitable for even the most demanding noise-sensitive applications. Many experts agree that noise reduction has been a key factor in expanding the usability of generator sets in urban and residential settings.

Emission Control Innovations for Environmental Responsibility

Environmental regulations are becoming increasingly stringent, driving significant innovation in generator emission control technologies. Modern generator sets are now equipped with sophisticated systems to reduce harmful emissions such as nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC). Technologies like catalytic converters, diesel particulate filters (DPFs), and selective catalytic reduction (SCR) systems are becoming commonplace, especially in larger diesel generators. Catalytic converters use chemical reactions to convert pollutants into less harmful substances. DPFs trap and remove particulate matter from the exhaust stream. SCR systems inject urea-based solutions into the exhaust to convert NOx into nitrogen and water. These technologies, often combined and optimized, enable generators to meet increasingly stringent emission standards, reducing their environmental footprint and contributing to cleaner air quality. Why is this emphasis on emission control so important? Beyond regulatory compliance, it reflects a growing societal awareness of environmental responsibility and the need for cleaner power generation, even in backup applications. It's about ensuring that essential power doesn't come at the cost of environmental degradation.

Catalytic Converters, DPFs, and SCR Systems

To illustrate the effectiveness of emission control technologies, consider the role of Selective Catalytic Reduction (SCR) systems. NOx emissions are a significant concern from diesel engines, contributing to smog and respiratory problems. SCR systems are designed to specifically target and reduce NOx emissions. They work by injecting a urea-based solution, often referred to as diesel exhaust fluid (DEF), into the exhaust stream upstream of a catalytic converter. The heat of the exhaust and the catalyst in the converter cause a chemical reaction between the urea and NOx, converting the harmful nitrogen oxides into harmless nitrogen and water vapor. Diesel Particulate Filters (DPFs) tackle another major pollutant – particulate matter, or soot. DPFs are essentially filters that trap soot particles from the exhaust. These filters periodically undergo a regeneration process, where the accumulated soot is burned off at high temperatures, ensuring the filter remains effective. Catalytic converters, in their various forms (diesel oxidation catalysts, three-way catalysts), address a broader range of pollutants, including CO and HC, through oxidation and reduction reactions. The integration of these emission control technologies represents a significant engineering achievement, enabling cleaner and more sustainable operation of generator sets. It's frankly amazing how effectively these systems can mitigate harmful emissions.

Hybrid Generator Sets and Energy Storage Integration

Looking towards the future, hybrid generator sets and energy storage integration are emerging as exciting trends. Hybrid systems combine a traditional generator with battery storage, and sometimes renewable energy sources like solar panels. In these configurations, the batteries can handle peak loads and provide power during periods of low demand, while the generator kicks in only when needed to recharge the batteries or meet high power requirements. This approach offers several advantages, including reduced fuel consumption, lower emissions, quieter operation, and improved efficiency. Energy storage integration, often using advanced lithium-ion batteries, allows for seamless transitions between battery power and generator power, ensuring uninterrupted power supply. Hybrid systems are particularly well-suited for applications with fluctuating power demands or where noise and emissions are critical concerns. Have you considered the potential benefits of a system that intelligently combines generator power with battery storage? This hybrid approach is paving the way for more sustainable and versatile power solutions, blurring the lines between traditional generators and renewable energy systems. It's an exciting evolution in power generation technology.

Compact and Portable Generator Technologies

While large stationary generators are essential for many applications, there's also a growing demand for compact and portable power solutions. Advancements in lightweight materials, inverter technology, and engine miniaturization are driving innovation in portable generator sets. Inverter generators, in particular, are gaining popularity due to their ability to produce clean, stable power suitable for sensitive electronics, as well as their quieter operation and lighter weight compared to traditional portable generators. The use of advanced composite materials and smaller, more efficient engines is further reducing the size and weight of portable units, making them easier to transport and deploy in various locations. These compact and portable generators are ideal for recreational use, construction sites, emergency backup power for homes, and remote locations where access to grid power is limited. Think about the convenience of having a reliable power source that you can easily take with you wherever you go. The advancements in portable generator technology are expanding the accessibility of backup power and enabling new applications in diverse settings. It’s impressive how much power can now be packed into such small and lightweight packages.

Digital Paralleling and Load Sharing Capabilities

For applications requiring significant power capacity or redundancy, digital paralleling and load sharing technologies are becoming increasingly important. Modern generator sets can be digitally paralleled, meaning multiple generators can be connected to operate together as a single, larger power system. Sophisticated control systems ensure seamless synchronization and load sharing between the generators, optimizing efficiency and reliability. Load sharing capabilities distribute the power demand evenly across the paralleled generators, preventing overloading and maximizing fuel efficiency. Digital paralleling offers several advantages over traditional paralleling methods, including greater flexibility, scalability, and control. It allows for modular power systems that can be easily expanded or reconfigured as power needs change. Redundancy is also enhanced, as if one generator in a paralleled system fails, the others can continue to operate, ensuring uninterrupted power supply. Why is this paralleling capability so valuable? It provides a scalable, reliable, and efficient way to meet large power demands and ensure business continuity in critical applications. It's about building power systems that are both powerful and resilient.

The Future of Generator Set Technology: Integration and Intelligence

Looking ahead, the future of generator set technology points towards even greater integration and intelligence. We can expect to see further advancements in smart controls, with AI-driven optimization of generator performance, predictive maintenance becoming even more sophisticated, and seamless integration with smart grids and energy management systems. The exploration of alternative fuels will continue, with a potential shift towards hydrogen fuel cells and other zero-emission technologies for generator applications. Hybrid systems will likely become more prevalent, blurring the lines further between generators, battery storage, and renewable energy sources. The focus on noise and emission reduction will intensify, driven by stricter regulations and growing environmental consciousness. Generator sets are evolving from standalone power sources into integral components of broader energy ecosystems, playing a crucial role in ensuring reliable, sustainable, and resilient power for a variety of applications. It’s clear that the technological journey of generator sets is far from over, and the innovations we’re seeing today are just the beginning of an exciting transformation. Staying informed about these latest technologies is crucial for anyone involved in power generation and backup power solutions.

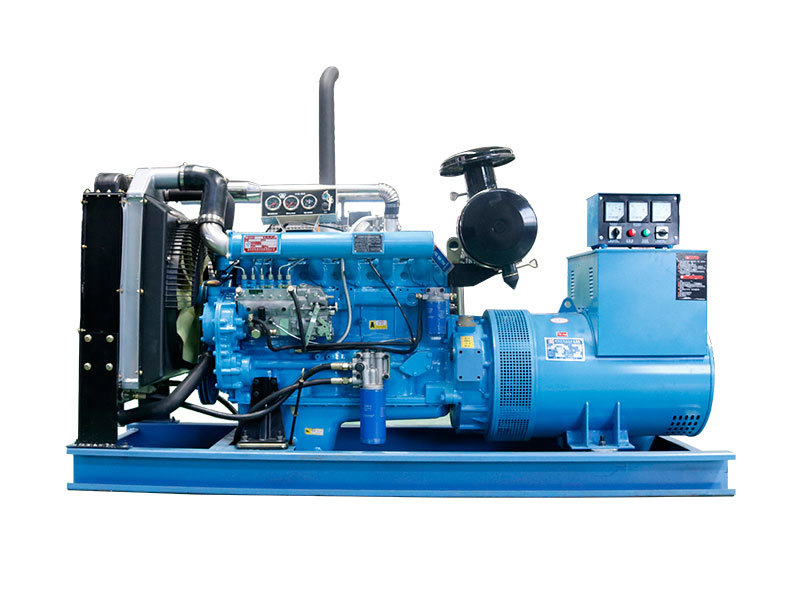

Our company is committed to providing cutting-edge generator set solutions that incorporate these latest technologies. We understand the critical importance of reliable, efficient, and environmentally responsible power. Our range of generator sets is designed to meet the evolving needs of our customers, incorporating smart controls, fuel-efficient engines, noise reduction features, and emission control systems. We are continuously innovating and integrating the latest advancements to ensure our products deliver superior performance and value. Whether you require backup power for a small business, a large industrial complex, or a critical infrastructure facility, we have the expertise and the technology to provide the right solution. We are dedicated to helping our customers navigate the complexities of modern power generation and choose the generator set that best meets their specific requirements. From initial consultation to installation and ongoing support, we are your trusted partner in power.

For more detailed information, please visit our official website: generator sets