Power outages, whether due to severe weather, grid failures, or unexpected events, can disrupt lives and businesses significantly. In these critical moments, a standby generator set becomes an indispensable asset, providing a reliable source of electricity when the main grid fails. However, having a generator is only half the battle. The real assurance comes from knowing that your generator set is not just present, but also primed and ready to perform flawlessly when an emergency strikes. Ensuring this readiness is not a matter of luck; it's a result of diligent maintenance, regular checks, and a proactive approach to preparedness. Neglecting these crucial steps can lead to disappointment and frustration when you need your generator most, rendering it a useless piece of equipment in your time of need. This article will delve into the essential practices and procedures to guarantee your generator set is a dependable source of emergency power, giving you peace of mind and protection against unforeseen power disruptions.

Fuel System Vigilance: The Lifeline of Your Generator

The fuel system is undeniably the heart of your generator set. Without a reliable fuel supply, even the most robust generator is rendered useless. Therefore, ensuring the integrity and readiness of the fuel system is paramount. This starts with the fuel itself. For diesel generators, which are common in standby applications due to their reliability and fuel efficiency, fuel quality is critical. Diesel fuel can degrade over time, especially if stored improperly. Water contamination, microbial growth, and oxidation are common issues that can lead to fuel degradation. Regularly inspect your fuel storage tank for any signs of water ingress or sediment buildup. Consider using fuel stabilizers, especially if you anticipate the fuel sitting in the tank for extended periods. These stabilizers help prevent fuel degradation and maintain its combustion properties. Furthermore, ensure your fuel lines are free from leaks and blockages. A simple visual inspection can often reveal cracks or damage. Fuel filters are another crucial component; they prevent contaminants from reaching the engine. Regularly replacing fuel filters according to the manufacturer's recommendations is essential for optimal performance and preventing engine damage. Don’t underestimate the importance of a clean and well-maintained fuel system – it’s the foundation of your generator's reliability.

Cooling System Checks: Preventing Overheating Emergencies

Just like a car engine, a generator set engine generates significant heat during operation. An effective cooling system is vital to dissipate this heat and prevent overheating, which can lead to serious engine damage and generator failure. The cooling system typically consists of a radiator, coolant, hoses, and a water pump. Regularly checking the coolant level is a simple but crucial task. Low coolant levels can indicate leaks in the system, which need to be addressed promptly. Inspect the radiator for any signs of damage, blockage from debris, or corrosion. Clean the radiator fins regularly to ensure proper airflow and heat dissipation. Examine coolant hoses for cracks, leaks, or swelling. Hoses can deteriorate over time due to heat and pressure, and replacing them proactively can prevent unexpected failures. Coolant itself should be replaced periodically according to the manufacturer's guidelines. Coolant not only prevents freezing in cold weather and boiling in hot weather, but also contains corrosion inhibitors that protect the engine's internal components. Over time, these inhibitors deplete, reducing the coolant's effectiveness. A well-maintained cooling system ensures your generator can run reliably for extended periods, even under heavy load, without the risk of overheating and costly repairs. It's a key aspect of emergency preparedness that should not be overlooked.

Lubrication System Maintenance: Ensuring Smooth Operation

The lubrication system is the unsung hero of any engine, including your generator set's engine. It ensures that all moving parts are properly lubricated, reducing friction and wear, and preventing catastrophic engine failure. Engine oil is the lifeblood of the lubrication system. Regularly checking the engine oil level is a fundamental maintenance task. Low oil levels can lead to increased friction, overheating, and engine damage. Follow the manufacturer's recommendations for oil change intervals. Over time, engine oil degrades and loses its lubricating properties. Dirty oil can also contain contaminants that accelerate engine wear. When changing the oil, always replace the oil filter as well. The oil filter removes contaminants from the oil, keeping it clean and effective. Inspect for any oil leaks around the engine. Leaks not only reduce oil levels but can also indicate underlying problems that need attention. The type of engine oil used is also important. Use the oil viscosity and specification recommended by the generator manufacturer. Using the wrong type of oil can lead to inadequate lubrication and engine damage. A well-lubricated engine runs smoother, more efficiently, and lasts longer. Maintaining the lubrication system is a critical investment in the long-term reliability and performance of your generator set, ensuring it's ready to power through any emergency.

Battery System Health: Powering the Starting System

In many standby generator sets, especially those designed for automatic startup during power outages, the battery system plays a crucial role. The battery provides the power to start the engine. A weak or dead battery means your generator won't start when you need it most. Therefore, maintaining the battery system is essential for emergency readiness. Regularly inspect the battery terminals for corrosion. Corrosion can impede electrical flow and prevent the generator from starting. Clean battery terminals with a wire brush and apply a terminal protectant to prevent future corrosion. Check the battery electrolyte level if your battery is not a maintenance-free type. Low electrolyte levels can reduce battery capacity and lifespan. If necessary, add distilled water to the correct level. Test the battery voltage regularly using a multimeter. A healthy battery should maintain a voltage within the manufacturer's specifications. Battery load testing is also recommended periodically to assess the battery's ability to deliver power under load. This test simulates the starting process and reveals if the battery is weak or failing. Consider using a battery maintainer or trickle charger to keep the battery fully charged, especially if the generator is not exercised frequently. A fully charged battery is more likely to start the generator reliably when an emergency occurs. Don't underestimate the importance of a healthy battery – it's the key to initiating the entire emergency power system.

Regular Exercise and Testing: Putting Your Generator Through Its Paces

Simply having a generator and performing basic maintenance checks is not enough to guarantee its readiness. Regular exercise and testing are crucial to ensure that all components are functioning correctly and that the generator will perform as expected during an actual power outage. Generator exercise involves running the generator periodically, typically under load, for a specified duration. This exercise helps to lubricate engine parts, burn off moisture buildup, and ensure that all mechanical and electrical components are in working order. Follow the generator manufacturer's recommendations for exercise frequency and duration. Monthly exercise is often recommended, but more frequent exercise may be beneficial in harsh environments or for critical applications. Load testing is an important aspect of generator testing. It involves running the generator under a significant electrical load, simulating real-world operating conditions. Load testing verifies that the generator can handle the expected power demand and that the voltage and frequency are stable under load. Consider using a load bank for accurate and controlled load testing. During exercise and testing, monitor the generator's performance closely. Check for any unusual noises, vibrations, leaks, or smoke. Observe the voltage and frequency readings to ensure they are within acceptable limits. Regular exercise and testing not only identify potential problems before they become critical but also ensure that you and anyone who needs to operate the generator are familiar with its operation and controls. Think of it as a fire drill for your emergency power system – practice makes perfect and ensures preparedness when it truly matters.

Developing a Proactive Maintenance Schedule: Prevention is Better Than Cure

Reactive maintenance, waiting for something to break before fixing it, is not a sustainable approach for ensuring generator readiness. A proactive maintenance schedule is essential for preventing problems and maximizing the lifespan and reliability of your generator set. Develop a checklist of maintenance tasks based on the generator manufacturer's recommendations and your specific operating environment. This checklist should include routine inspections, fluid level checks, filter replacements, battery tests, and exercise schedules. Establish a schedule for performing these tasks, typically based on operating hours or calendar intervals. For example, oil and filter changes may be recommended every 250 hours of operation or annually, whichever comes first. Keep detailed records of all maintenance activities, including dates, tasks performed, and any findings. These records provide a valuable history of your generator's maintenance and can help track trends and identify potential issues early on. Regularly review your maintenance schedule and adjust it as needed based on your experience and the generator's performance. Don't hesitate to consult with a qualified generator technician to develop a customized maintenance plan tailored to your specific generator model and application. A proactive maintenance schedule is an investment in peace of mind, ensuring that your generator is always ready to provide reliable emergency power when you need it most. It's about taking control and preventing breakdowns, rather than reacting to them when it's already too late.

When to Call the Professionals: Recognizing Your Limits

While many generator maintenance tasks can be performed by a homeowner or facility maintenance staff, there are situations where it's crucial to call in professional generator technicians. Attempting complex repairs or diagnostics without the proper training and equipment can be risky and potentially damage the generator further, or even pose safety hazards. If you encounter any major issues during routine checks or testing, such as significant leaks, unusual noises, or persistent starting problems, it's best to seek professional help. Scheduled preventative maintenance, especially for larger or more complex generator sets, is often best handled by qualified technicians. They have the expertise, tools, and experience to perform thorough inspections, identify potential problems, and carry out necessary maintenance tasks to ensure optimal performance. When selecting a generator service provider, choose a reputable company with experienced technicians who are familiar with your generator model. Inquire about their certifications and training to ensure they are qualified to work on your equipment. Establish a relationship with a reliable service provider for ongoing maintenance and emergency repairs. Having a trusted partner to rely on can provide peace of mind and ensure that your generator is always in expert hands. Knowing when to seek professional help is not a sign of weakness, but rather a smart and responsible approach to generator maintenance, ensuring both safety and long-term reliability. It's about recognizing your limitations and leveraging expertise when it's needed most.

Interactive Questions for Readiness Reflection

To truly ensure your generator set is ready for emergencies, it's not just about performing tasks; it's about actively thinking and reflecting on your preparedness. Have you recently reviewed your generator's maintenance log? Taking a moment to look back at the maintenance history can highlight any overdue tasks or recurring issues that need attention. Do you know where your generator's manual is and have you familiarized yourself with its troubleshooting section? In an emergency, quick access to the manual can be invaluable for resolving minor issues. Have you physically inspected your generator within the last month, checking fluid levels, battery connections, and for any signs of damage or wear? Regular visual inspections are a simple yet effective way to catch potential problems early. Do you have a plan for refueling your generator during an extended power outage, and have you considered fuel storage safety and accessibility? Fuel management is crucial for prolonged outages. Finally, have you actually tested your generator under load recently, or are you just assuming it will work when the time comes? Putting your generator to the test is the ultimate proof of its readiness. Answering these questions honestly can help you identify any gaps in your preparedness and take proactive steps to address them, ensuring your generator is truly ready when you need it most.

Conclusion: Peace of Mind in Every Watt

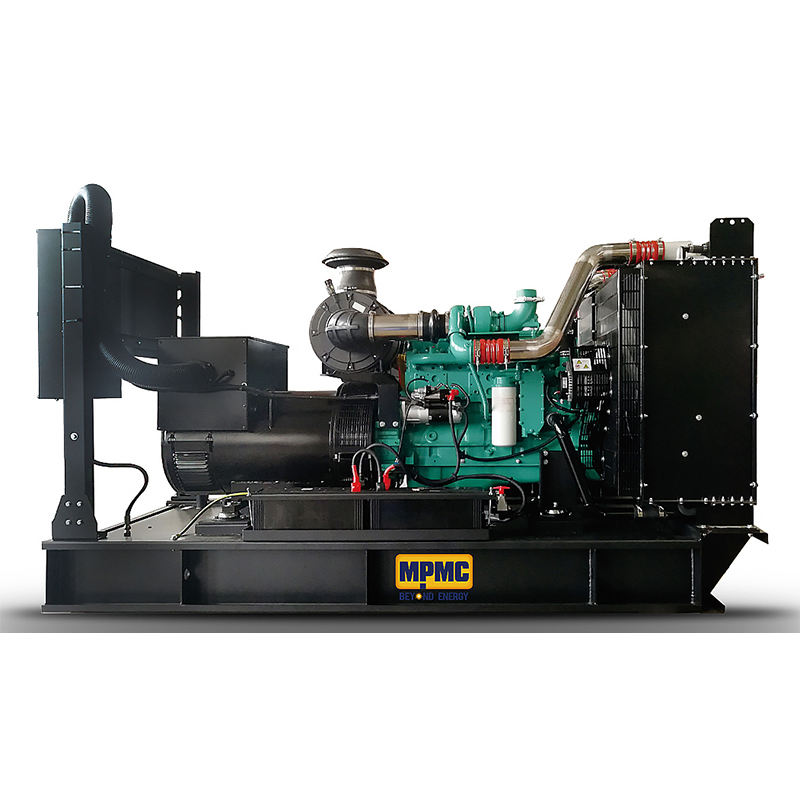

Ensuring your generator set is truly ready for emergencies is an ongoing commitment, not a one-time task. It requires a combination of regular maintenance, diligent inspections, proactive planning, and a willingness to invest the time and resources necessary to keep your standby power system in peak condition. By prioritizing fuel system vigilance, cooling and lubrication system checks, battery health, regular exercise, and a proactive maintenance schedule, you significantly increase the reliability and lifespan of your generator. Remember, a generator that is not properly maintained is not a reliable generator. It’s a potential source of frustration and disappointment when you need it most. Taking the steps outlined in this article will not only ensure your generator is ready to perform flawlessly during an emergency but also provide you with invaluable peace of mind, knowing that you have a dependable source of backup power to protect your home or business from the disruptions of power outages. Our company understands the critical importance of reliable emergency power. We offer a range of generator sets designed for robust performance and ease of maintenance, along with comprehensive service and support to help you keep your generator in top condition. Investing in preparedness is investing in security and peace of mind. Make sure your generator is not just an asset on paper, but a truly reliable source of power when the lights go out.

For more detailed information, please visit our official website: generator maintenance