In today's world, where uninterrupted power supply is not just a convenience but a necessity for critical operations across various industries, the reliability and efficiency of power generation systems are paramount. Generator sets, often the backbone of backup and prime power solutions, are increasingly required to perform under demanding conditions, necessitating advanced technologies like parallel operation. Parallel operation technology for generator sets isn't just about connecting multiple generators together; it's a sophisticated approach to power management that ensures seamless switching between power sources, optimal load distribution, and enhanced system resilience. Have you ever considered what happens when a single generator fails in a large facility? The potential disruptions can be significant, ranging from data loss in data centers to critical equipment shutdown in hospitals. This is where the elegance and robustness of parallel operation truly shine, providing a solution that minimizes downtime and maximizes operational continuity. In essence, it's about creating a power system that is greater than the sum of its parts, offering scalability, redundancy, and efficiency that are simply unattainable with standalone generator configurations.

Understanding Seamless Switching in Parallel Generator Systems

Seamless switching, at its core, is the ability to transition between different power sources—typically the main grid and generator sets, or between multiple generator sets themselves—without any noticeable interruption to the connected load. This is a critical feature, especially for sensitive equipment and processes that cannot tolerate even momentary power dips. In a parallel generator system, seamless switching is achieved through a combination of advanced control systems, sophisticated synchronization mechanisms, and fast-acting transfer switches. The process begins with the continuous monitoring of the primary power source, often the utility grid. When a grid failure is detected, the parallel generator system is automatically initiated. The generators start up, synchronize with each other, and then, crucially, synchronize with the grid (if it's still partially available or expected to return soon). The transfer to generator power must be smooth and instantaneous, ensuring that the load experiences no break in power supply. This intricate dance of synchronization and switching is what defines seamless operation, and it requires precision engineering and robust control algorithms. Think about a hospital operating room during a critical surgery – a power outage, even for a fraction of a second, could have devastating consequences. Seamless switching ensures that the backup generators kick in without a hitch, maintaining a stable power supply throughout the procedure. It's a testament to the technological advancements in power management that such transitions can occur virtually imperceptibly.

The Importance of Load Distribution in Parallel Operation

Beyond seamless switching, effective load distribution is another cornerstone of parallel generator operation. When multiple generators are working together, it’s not enough for them to simply produce power; that power needs to be intelligently and equitably distributed among the generators based on their capacity and operational status. Load distribution, also known as load sharing, ensures that no single generator is overloaded while others are underutilized. This balanced approach not only optimizes fuel efficiency and reduces wear and tear on individual generators but also enhances the overall stability and longevity of the parallel system. Modern parallel control systems employ sophisticated load sharing strategies, such as droop control or isochronous control, to dynamically adjust the power output of each generator in response to changing load demands. Droop control, for instance, allows generators to proportionally share the load based on their governor settings, while isochronous control aims to maintain a constant frequency across the system, with one generator acting as the frequency master. Proper load distribution is vital for preventing premature failures and ensuring that the system can reliably meet the power demands of the connected load, even under fluctuating conditions. Consider a large industrial complex with varying power needs throughout the day. During peak production hours, the demand is high, but during off-peak times, it's significantly lower. A well-designed parallel system with effective load distribution will automatically adjust the number of generators online and their individual outputs to match the fluctuating load, maximizing efficiency and minimizing fuel consumption.

Synchronization Technologies for Parallel Generator Sets

Synchronization is the linchpin of successful parallel operation. Before connecting generators in parallel or switching between power sources, it's absolutely essential to ensure that they are synchronized – meaning they are operating at the same frequency, voltage, and phase angle. Mismatched synchronization can lead to severe consequences, including equipment damage, system instability, and even power outages. Modern synchronization systems utilize advanced electronic controllers and sensors to precisely measure and adjust these parameters. Automatic synchronizers continuously monitor the incoming generator's voltage, frequency, and phase relative to the bus voltage. They then send control signals to the generator's governor and voltage regulator to fine-tune these parameters until synchronization is achieved within acceptable tolerances. Once synchronized, the synchronizer automatically closes the breaker to connect the generator to the parallel system. These systems often incorporate features like synchro-check, which prevents breaker closure if synchronization conditions are not met, adding an extra layer of safety and reliability. In my experience, robust synchronization systems are non-negotiable for any parallel generator installation. They are the silent guardians ensuring smooth and safe transitions, preventing potentially catastrophic events. Think of it like a perfectly choreographed dance – every generator must move in perfect harmony to avoid collisions and maintain a seamless flow of power.

Load Sharing Methods: Droop and Isochronous Control

As mentioned earlier, load sharing is crucial for optimizing the performance and longevity of parallel generator systems. Two primary methods dominate the landscape of load sharing: droop control and isochronous control. Droop control is perhaps the more widely used method due to its simplicity and inherent stability. In droop control, each generator is programmed with a slight “droop” in frequency as the load increases. This means that as a generator takes on more load, its frequency slightly decreases. This frequency droop characteristic allows generators to automatically share the load proportionally to their power ratings. Generators with higher power ratings will naturally contribute more to the load because they experience a smaller frequency droop for the same load change. Isochronous control, on the other hand, aims to maintain a constant frequency across the entire parallel system, regardless of load changes. In an isochronous system, one generator is designated as the “master” and is responsible for maintaining the system frequency. Other generators, operating in “slave” mode, adjust their power output to maintain this constant frequency set by the master. While isochronous control can provide tighter frequency regulation, it can also be more complex to implement and may be less stable than droop control in certain scenarios. Choosing between droop and isochronous control often depends on the specific application requirements and the desired balance between frequency stability and system robustness. Frankly speaking, for most standalone parallel generator applications, droop control offers a reliable and cost-effective solution, while isochronous control might be preferred in grid-parallel applications or where very precise frequency control is paramount.

Practical Applications of Parallel Operation Technology

The benefits of parallel operation technology extend across a diverse range of applications, wherever reliable and scalable power solutions are needed. Data centers, with their massive energy demands and zero-tolerance for downtime, are prime examples. Parallel generator systems ensure that data centers can maintain continuous operation even during extended grid outages, safeguarding critical data and services. Hospitals, similarly, rely heavily on parallel generator systems to power life-support equipment, operating rooms, and essential medical facilities during emergencies. Industrial facilities, from manufacturing plants to refineries, often utilize parallel generators for both prime power and backup power, enabling them to maintain production schedules and avoid costly disruptions. Emergency power systems in commercial buildings, airports, and transportation hubs also frequently employ parallel generator configurations to ensure the safety and functionality of these critical infrastructures during grid failures. Beyond these traditional applications, parallel operation is also finding increasing relevance in microgrids and renewable energy integration. As distributed generation becomes more prevalent, parallel generator systems can play a crucial role in integrating renewable sources like solar and wind power with traditional diesel or gas generators, creating resilient and sustainable energy solutions. Have you ever wondered how large events like concerts or outdoor festivals maintain consistent power for lighting, sound systems, and vendor stalls? Often, the answer lies in mobile parallel generator systems, providing temporary but robust power infrastructure where grid access might be limited or unreliable. The versatility and scalability of parallel operation technology make it an indispensable tool in ensuring power reliability across a wide spectrum of sectors.

Challenges and Considerations in Implementing Parallel Systems

While parallel operation technology offers significant advantages, its implementation is not without its challenges and considerations. Designing and commissioning a parallel generator system requires expertise in electrical engineering, control systems, and generator operation. The complexity of the control systems, particularly synchronization and load sharing algorithms, demands careful planning and configuration. Communication between generators and the central control system is critical for seamless operation, and robust communication networks are essential to prevent system failures. Maintenance of parallel generator systems can also be more complex than standalone units, requiring specialized knowledge and procedures to ensure the continued reliability of the system. Troubleshooting issues in a parallel system can be more intricate due to the interconnected nature of the generators and control components. It’s worth noting that the initial investment cost for a parallel system is typically higher than for a single generator of equivalent total capacity, due to the additional control equipment, synchronization gear, and paralleling switchgear. However, this upfront cost is often justified by the enhanced reliability, scalability, and operational flexibility that parallel operation provides. Furthermore, proper training for operators and maintenance personnel is crucial for the long-term success of a parallel generator installation. Understanding the intricacies of the control system, synchronization procedures, and load sharing mechanisms is vital for ensuring safe and efficient operation. In my experience, the key to overcoming these challenges lies in partnering with experienced system integrators and choosing reputable equipment manufacturers who can provide comprehensive support throughout the design, installation, commissioning, and maintenance phases. A well-planned and expertly executed parallel generator system will deliver long-term value and peace of mind, outweighing the initial complexities and investment.

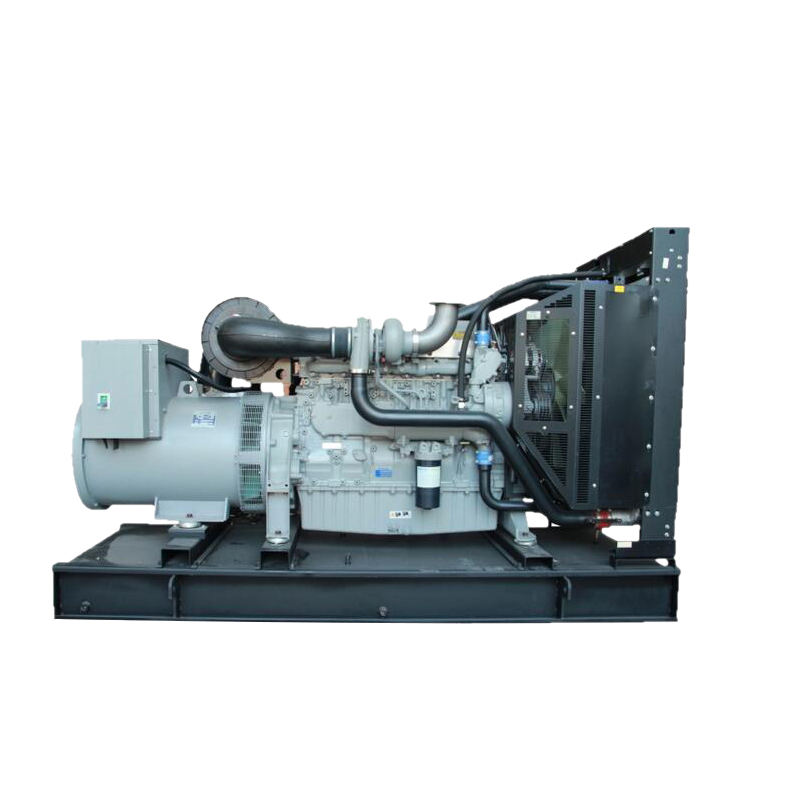

Our Solutions: Enhancing Power Reliability with Parallel Operation

At our company, we understand the critical importance of reliable power, and we are dedicated to providing advanced generator set solutions that meet the evolving demands of modern power systems. Our range of generator sets is specifically designed to excel in parallel operation configurations, offering seamless switching and precise load distribution capabilities. We offer a comprehensive suite of products and services to support parallel generator installations, including state-of-the-art control panels, automatic synchronizers, load sharing modules, and paralleling switchgear. Our control systems are engineered for ease of use and robust performance, featuring intuitive interfaces and advanced monitoring capabilities that provide operators with real-time insights into system operation. We also provide expert engineering support to assist our clients in designing and implementing parallel generator systems tailored to their specific needs. Our team of experienced engineers can guide you through every step of the process, from initial system design and equipment selection to installation, commissioning, and ongoing maintenance. Furthermore, we offer comprehensive training programs for operators and maintenance personnel, ensuring that your team is fully equipped to manage and maintain your parallel generator system effectively. We believe that investing in quality equipment and expert support is essential for achieving long-term power reliability. Our commitment to innovation and customer satisfaction drives us to continuously improve our products and services, ensuring that our clients have access to the most advanced and dependable parallel operation solutions available. By choosing our generator sets and parallel operation technologies, you are investing in a power system that is not only reliable and efficient but also scalable and adaptable to your future power needs. We are here to partner with you in building a resilient and robust power infrastructure that you can depend on, day in and day out.

Conclusion: Embracing Parallel Operation for Uninterrupted Power

In conclusion, parallel operation technology for generator sets represents a significant advancement in power system design, offering a robust and efficient solution for achieving seamless switching and optimal load distribution. From ensuring uninterrupted power in critical facilities like data centers and hospitals to enhancing the reliability of industrial operations and emergency power systems, the benefits of parallel operation are undeniable. The ability to seamlessly transition between power sources, coupled with intelligent load sharing, maximizes system uptime, improves fuel efficiency, and extends the lifespan of generator sets. While the implementation of parallel systems requires careful planning, expert engineering, and advanced control technologies, the rewards in terms of enhanced power reliability and operational flexibility are well worth the investment. As power demands continue to grow and the reliance on continuous power supply intensifies, parallel operation technology will only become more critical. Embracing this technology is not just about meeting current power needs; it’s about future-proofing your power infrastructure and ensuring that you are prepared for the challenges and opportunities of tomorrow’s energy landscape. By understanding the core concepts of seamless switching, load distribution, synchronization, and control strategies, and by partnering with experienced providers, you can harness the full potential of parallel operation to create a power system that is truly resilient, reliable, and ready for anything. The future of power reliability is undoubtedly intertwined with the continued evolution and adoption of parallel operation technologies, and we are proud to be at the forefront of this exciting and essential field.

For more detailed information, please visit our official website: Parallel Operation