The landscape of power generation is undergoing a significant transformation, driven by increasingly stringent environmental regulations worldwide. For businesses and industries reliant on generator sets for primary, backup, or emergency power, understanding and adapting to these new emission compliance standards is not just a matter of regulatory adherence; it’s becoming a core component of sustainable and responsible operations. These standards, aimed at reducing harmful pollutants like nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC), are pushing manufacturers and operators to rethink their approaches to generator set technology, operation, and maintenance. The transition isn't always straightforward, demanding a proactive and well-structured plan. This article delves into the critical aspects of these evolving emission standards, providing a comprehensive five-year preparation roadmap and exploring viable upgrade pathways to ensure your generator sets remain compliant and efficient in the years to come.

Understanding the Shifting Sands of Emission Regulations

To be honest, the tightening of emission regulations for generator sets is not a sudden development but rather a progressive evolution reflecting a global commitment to cleaner air and reduced environmental impact. Governments and regulatory bodies worldwide are increasingly focused on mitigating air pollution from various sources, and generator sets, especially diesel-powered ones, have come under increased scrutiny. These regulations often vary by region and application, creating a complex web of requirements for businesses operating across different geographical areas or sectors. For instance, standards in North America (EPA Tier standards), Europe (EU Stage V), and other regions are constantly being updated, often becoming more stringent with each revision cycle. Understanding the specific regulations applicable to your location and operational context is the crucial first step. It's worth noting that these standards are not just about new generator sets; they frequently impact existing fleets as well, necessitating retrofits or operational adjustments to maintain compliance and avoid penalties. The driving forces behind these changes are multifaceted, ranging from public health concerns related to air quality to international agreements aimed at combating climate change. This makes it clear that emission compliance is not a temporary hurdle but a long-term operational imperative.

Crafting a Five-Year Preparation Roadmap: A Phased Approach

Navigating the complexities of new emission standards requires a structured and forward-thinking approach. A five-year preparation roadmap provides a practical framework for businesses to proactively address these challenges, ensuring a smooth and cost-effective transition. This roadmap can be broadly divided into phases, starting with assessment and planning, moving through technology evaluation and selection, and culminating in implementation and ongoing monitoring. Phase 1, typically spanning the first year or two, should focus on a thorough assessment of your current generator set inventory. This involves documenting the specifications of each generator, including engine type, age, emission control technology (if any), and operational hours. Crucially, you need to identify which regulations are currently applicable and which ones are anticipated to come into effect within the five-year timeframe. This phase also includes developing a preliminary compliance strategy, outlining your overall goals and approach. Phase 2, in years two and three, shifts to technology evaluation and selection. This involves researching available emission reduction technologies, assessing their feasibility for your specific generator sets and operational needs, and evaluating their costs and benefits. This might include exploring engine modifications, aftertreatment systems, or even considering alternative fuels. Phase 3, in years three to five, is dedicated to implementation and upgrades. This is when you put your plan into action, whether it involves retrofitting existing generators, replacing older units with compliant models, or adjusting operational practices. Throughout this roadmap, continuous monitoring and review are essential to adapt to any changes in regulations or technology advancements. Frankly speaking, proactive planning is the key to avoiding last-minute scrambles and ensuring long-term compliance.

Exploring Upgrade Pathways for Existing Generator Sets

For many businesses, particularly those with substantial investments in existing generator set fleets, complete replacement is not always the most practical or financially viable option. Fortunately, a range of upgrade pathways exist to enhance the emission performance of older generator sets and bring them closer to compliance standards. One common approach involves engine modifications. This can include adjustments to the fuel injection system, combustion chamber design, or turbocharging systems to optimize combustion efficiency and reduce pollutant formation at the source. Another significant pathway is the integration of aftertreatment systems. These systems are designed to treat exhaust gases after they leave the engine, removing pollutants before they are released into the atmosphere. Common aftertreatment technologies include Selective Catalytic Reduction (SCR) for NOx reduction and Diesel Particulate Filters (DPF) for PM reduction. The choice of aftertreatment system depends on the specific pollutants targeted and the engine characteristics. It's important to note that retrofitting aftertreatment systems can be complex and may require modifications to the generator set's exhaust system, cooling system, and control systems. Furthermore, fuel system upgrades can also contribute to emission reduction. Switching to lower sulfur diesel fuel or exploring alternative fuels like biodiesel or natural gas can significantly reduce PM and other emissions. The feasibility and cost-effectiveness of each upgrade pathway need to be carefully evaluated on a case-by-case basis, considering the age and condition of the generator set, the desired level of emission reduction, and the available budget. In my experience, a thorough assessment by qualified engineers is crucial to determine the most appropriate and effective upgrade strategy.

The Role of Fuel and Operational Practices in Emission Reduction

While technological upgrades are essential, achieving and maintaining emission compliance is not solely reliant on hardware modifications. Fuel quality and operational practices play a crucial supporting role in minimizing generator set emissions. The type of fuel used directly impacts the levels of pollutants emitted. Lower sulfur diesel fuels, now widely mandated in many regions, significantly reduce sulfur dioxide emissions and particulate matter formation. Exploring alternative fuels, such as biodiesel blends or natural gas, can offer further emission reduction benefits, although they may require engine modifications or dedicated infrastructure. Beyond fuel, operational practices are equally important. Regular maintenance, including engine tuning, air filter replacement, and injector cleaning, ensures that the generator set operates at peak efficiency and minimizes unnecessary emissions. Proper load management is another key aspect. Operating generator sets at their optimal load range, typically around 75-85% of rated capacity, promotes cleaner combustion and reduces fuel consumption. Avoiding prolonged idling and unnecessary operation also contributes to emission reduction and extends the lifespan of the generator set. Moreover, implementing robust monitoring systems to track engine performance and emission levels can help identify potential issues early and ensure timely corrective actions. Have you ever considered how much fuel efficiency and emission levels can be improved simply through optimized operational procedures? It's often an overlooked but highly effective aspect of emission management.

Navigating the Regulatory Maze: Staying Ahead of the Curve

The regulatory landscape for generator set emissions is constantly evolving, with new standards and revisions being introduced at both national and regional levels. Staying ahead of this curve requires proactive monitoring of regulatory developments and a commitment to continuous learning. Regularly consulting with regulatory agencies and industry associations is essential to stay informed about upcoming changes and interpretations of existing standards. Subscribing to industry publications and participating in relevant conferences and workshops can also provide valuable insights into emerging trends and best practices in emission compliance. It’s also beneficial to establish relationships with environmental consultants and emission testing laboratories. These experts can provide guidance on navigating complex regulations, conducting emission testing, and developing compliance strategies tailored to your specific needs. Furthermore, implementing a robust record-keeping system is crucial for demonstrating compliance to regulatory authorities. This includes maintaining documentation of generator set specifications, maintenance records, emission testing reports, and any upgrades or modifications performed. In the long run, proactive engagement with the regulatory environment not only ensures compliance but also positions your business as environmentally responsible and forward-thinking. Frankly speaking, understanding the regulatory maze is half the battle in achieving emission compliance.

Five-Year Roadmap: Year-by-Year Breakdown for Proactive Preparation

To make the five-year preparation roadmap more concrete, let's break it down into actionable steps for each year:

- Year 1: Assessment and Awareness. Focus on understanding the current and upcoming emission regulations applicable to your generator sets. Conduct a comprehensive inventory of your existing fleet, documenting key specifications and operational data. Begin initial research into available emission reduction technologies and potential upgrade pathways.

- Year 2: In-Depth Analysis and Planning. Conduct a detailed analysis of your generator set inventory to identify units that are most likely to be affected by new regulations. Engage with experts to assess the feasibility of different upgrade options for your specific equipment. Develop a preliminary budget and timeline for compliance measures.

- Year 3: Technology Selection and Pilot Projects. Finalize the selection of emission reduction technologies or upgrade pathways based on your analysis and budget. Consider implementing pilot projects on a small number of generator sets to test the chosen technologies in real-world operating conditions and gather performance data.

- Year 4: Implementation and Retrofitting. Begin the implementation phase, which may involve retrofitting existing generator sets with aftertreatment systems or other upgrades, or procuring new compliant generator sets to replace older units. Develop a detailed implementation schedule and manage the upgrade process systematically.

- Year 5: Verification and Ongoing Compliance. Conduct thorough emission testing to verify the effectiveness of implemented upgrades and ensure compliance with the required standards. Establish ongoing monitoring and maintenance procedures to sustain emission performance and address any future compliance challenges. Review and update your roadmap annually to adapt to any changes in regulations or technology.

The Economic and Environmental Benefits of Emission Compliance

While the initial investment in emission compliance upgrades might seem like a cost burden, it's crucial to recognize the significant economic and environmental benefits that accrue in the long run. From an economic perspective, compliance avoids potential penalties and fines associated with violating emission regulations. Moreover, investing in fuel-efficient technologies and optimized operational practices can lead to substantial fuel cost savings over the lifespan of the generator set. In some regions, government incentives or grants may be available to support businesses in adopting cleaner technologies, further offsetting the initial investment. Environmentally, emission compliance directly contributes to improved air quality, reducing the negative impacts of pollutants on public health and ecosystems. Lowering emissions of greenhouse gases also aligns with broader sustainability goals and helps mitigate climate change. Furthermore, adopting cleaner technologies can enhance a company's corporate social responsibility (CSR) profile and improve its reputation among stakeholders, including customers, employees, and investors. Interestingly enough, many businesses are finding that a commitment to environmental sustainability is becoming a competitive advantage, attracting environmentally conscious customers and investors. In essence, emission compliance is not just a regulatory obligation but also a strategic investment that yields both economic and environmental returns.

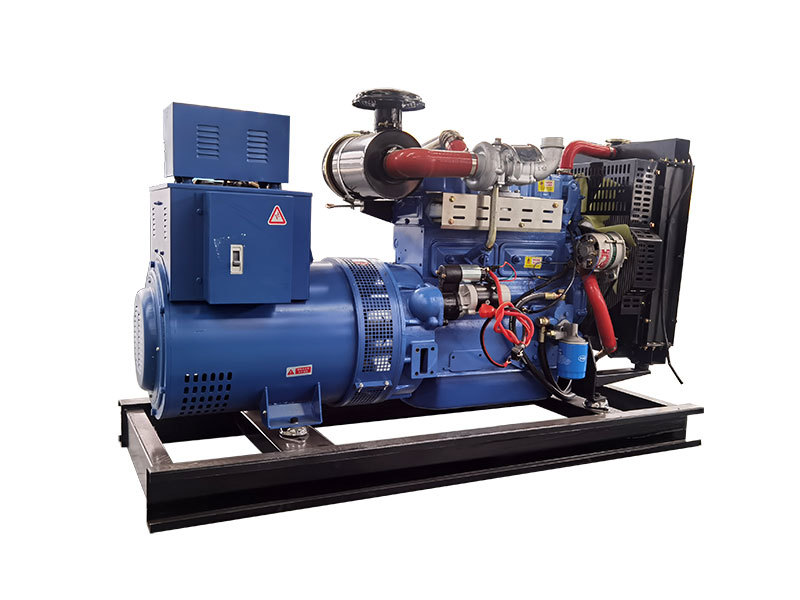

Our Commitment to Supporting Your Emission Compliance Journey

At our company, we understand the challenges businesses face in navigating the evolving landscape of emission compliance standards for generator sets. We are committed to providing comprehensive solutions and support to help you achieve and maintain compliance effectively and efficiently. Our range of generator sets is designed to meet the latest emission standards, incorporating advanced engine technologies and aftertreatment systems to minimize pollutant emissions. We offer a variety of models to suit diverse power requirements and applications, ensuring that you can find a compliant solution tailored to your specific needs. Beyond new equipment, we also provide retrofit and upgrade services for existing generator sets. Our experienced engineers can assess your current fleet and recommend appropriate upgrade pathways, including engine modifications and aftertreatment system integration. We offer turnkey solutions, managing the entire upgrade process from initial assessment to installation and commissioning. Furthermore, we provide ongoing maintenance and support services to ensure the continued performance and compliance of your generator sets. Our service agreements can be customized to include regular maintenance checks, emission testing, and remote monitoring, providing peace of mind and minimizing downtime. We believe that a proactive and collaborative approach is essential for successful emission compliance, and we are dedicated to partnering with our customers to navigate this journey effectively. Why is this approach so effective? Because we focus on providing tailored solutions and expert guidance, ensuring that our customers not only meet regulatory requirements but also optimize their generator set operations for long-term sustainability and efficiency.

Conclusion: Embracing Proactive Preparation for a Cleaner Future

In conclusion, the implementation of new emission compliance standards for generator sets represents a significant shift towards cleaner and more sustainable power generation. While these standards present challenges, they also offer opportunities for innovation, efficiency improvements, and enhanced environmental stewardship. The key to successfully navigating this transition lies in proactive preparation and a well-defined five-year roadmap. By understanding the evolving regulatory landscape, assessing your current generator set inventory, exploring upgrade pathways, and adopting best operational practices, you can ensure compliance and reap the associated economic and environmental benefits. Embracing a forward-thinking approach not only mitigates risks but also positions your business as a leader in environmental responsibility, contributing to a cleaner and healthier future for all. The journey towards emission compliance is a continuous one, but with careful planning and the right partnerships, it is a journey that can be navigated successfully, ensuring both operational efficiency and environmental sustainability.

For more detailed information, please visit our official website: Generator Sets