The design of a generator set enclosure is a multifaceted engineering challenge, demanding a delicate equilibrium between several critical performance parameters. It's not merely about constructing a box around a generator; it’s about creating a sophisticated system that simultaneously addresses cooling requirements, noise attenuation, and robust security. To be honest, achieving this balance is often where the true expertise in enclosure design shines. Ignoring any one of these aspects can lead to significant operational issues, ranging from overheating and reduced lifespan to unacceptable noise levels and security breaches. Therefore, a comprehensive understanding of each element and their interdependencies is paramount for effective enclosure design. This article will delve into the intricacies of these three core components, exploring the challenges and solutions involved in creating enclosures that are both functional and efficient.

The Imperative of Effective Cooling

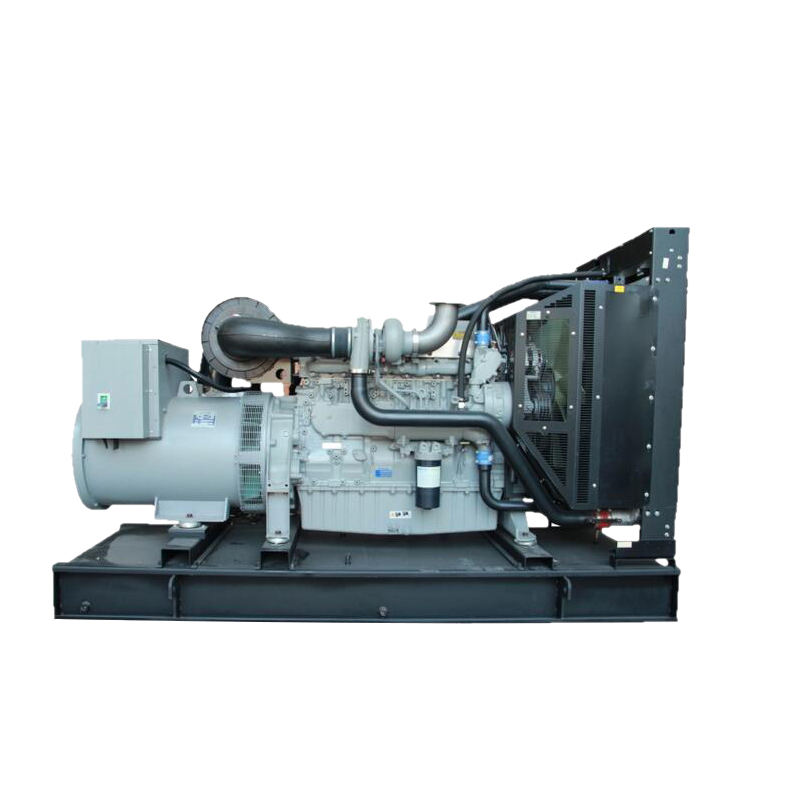

Generator sets, by their very nature, generate a substantial amount of heat during operation. This heat is a byproduct of the combustion process and the mechanical friction within the engine and alternator. If this heat is not effectively managed, it can lead to a multitude of problems, including decreased engine efficiency, premature component wear, and even catastrophic failures. Therefore, adequate cooling is not just a desirable feature in a generator enclosure; it’s an absolute necessity for ensuring reliable and long-term operation. The enclosure design must facilitate sufficient airflow to dissipate this heat, often requiring carefully planned ventilation systems, strategically placed inlets and outlets, and sometimes even forced air cooling systems. Factors such as the generator's size, operating environment, and duty cycle all play a crucial role in determining the cooling requirements and the complexity of the ventilation design. It's worth noting that simply providing openings isn't enough; the airflow path and volume must be precisely calculated to ensure efficient heat removal without compromising other enclosure functions.

Noise Reduction: Creating a Quieter Operation

Generator sets, especially larger diesel or gas models, are inherently noisy machines. The combustion process, mechanical movement, and exhaust emissions all contribute to significant noise pollution. In residential areas, commercial zones, or any environment where noise levels are regulated, effective noise reduction is paramount. Generator set enclosures play a crucial role in mitigating this noise, acting as a barrier to sound waves and reducing the overall noise footprint of the generator. This is typically achieved through the use of sound-attenuating materials within the enclosure walls, doors, and ventilation systems. The design must consider the frequencies of the noise generated and select appropriate materials and construction techniques to effectively dampen these frequencies. Interestingly enough, achieving optimal noise reduction often involves a trade-off with cooling, as increased soundproofing can sometimes restrict airflow. Therefore, a balanced approach is essential, incorporating noise reduction measures without compromising the cooling capacity of the enclosure. The goal is to create an enclosure that significantly reduces noise levels while still maintaining adequate ventilation for heat dissipation.

Security Considerations: Protecting the Asset

Beyond operational performance, security is another critical aspect of generator set enclosure design. Generators represent a significant investment and are often vital for critical infrastructure or business continuity. Protecting them from theft, vandalism, and unauthorized access is therefore a primary concern. Enclosures provide a physical barrier, deterring opportunistic theft and vandalism. Robust construction, secure locking mechanisms, and even alarm systems can be integrated into the enclosure design to enhance security. Furthermore, enclosures can also offer protection from environmental factors such as extreme weather conditions, dust, and debris, which can damage the generator and reduce its lifespan. In some cases, security considerations may also extend to preventing unauthorized modifications or tampering with the generator set itself. The level of security required will depend on the location of the generator, the value of the asset, and the potential consequences of theft or damage. Frankly speaking, a well-designed enclosure acts as a first line of defense, safeguarding the generator and ensuring its continued availability.

Balancing Act: Cooling and Noise Reduction

The challenge in generator set enclosure design truly lies in the delicate balancing act between cooling, noise reduction, and security. Cooling and noise reduction, in particular, often present conflicting design requirements. Effective noise reduction typically involves minimizing openings and using dense, sound-absorbing materials. However, these same measures can restrict airflow and hinder cooling. For instance, thicker enclosure walls and tightly sealed doors, while excellent for noise attenuation, can impede ventilation and trap heat. Similarly, complex labyrinthine air intake and exhaust systems designed to reduce noise can also restrict airflow and increase backpressure on the generator's cooling system. Therefore, designers must employ innovative strategies to overcome these conflicts. This might involve using specialized ventilation systems that incorporate sound attenuators, designing airflow pathways that maximize cooling while minimizing noise leakage, or employing advanced materials that offer both sound insulation and thermal conductivity. The key is to find a harmonious solution where neither cooling nor noise reduction is compromised at the expense of the other.

Security Without Sacrificing Cooling

Integrating security features into a generator set enclosure must also be done without compromising its cooling capabilities. While security measures like solid walls and locked doors are essential, they can also restrict airflow and contribute to heat buildup. The design must ensure that security features do not inadvertently create thermal management issues. For example, if security grilles are used over ventilation openings, they must be designed to minimize airflow restriction while still providing adequate security. Similarly, the placement of security components should not obstruct ventilation pathways or impede the effectiveness of cooling fans. It's also crucial to consider the materials used in security features. Some materials, like heavy steel, can absorb and retain heat, potentially exacerbating cooling challenges. Therefore, careful material selection and strategic placement of security elements are vital to maintain both security and effective cooling. The objective is to create a secure enclosure that still allows for ample airflow and efficient heat dissipation, ensuring the generator operates within its optimal temperature range.

Noise Reduction and Security: Synergistic Design

Interestingly enough, noise reduction and security can sometimes be addressed synergistically in enclosure design. Many materials that are effective for sound attenuation, such as dense composites and laminated panels, also offer enhanced physical security due to their inherent strength and resistance to penetration. By selecting appropriate materials, designers can simultaneously improve both noise reduction and security without necessarily adding separate components. For instance, a heavy-gauge steel enclosure with internal sound-absorbing lining provides both a robust physical barrier and effective noise dampening. Furthermore, designing enclosures with minimal external access points not only enhances security but also reduces potential noise leakage paths. By considering these factors holistically, it's possible to create enclosure designs that effectively address both noise reduction and security in a mutually reinforcing manner. The key is to identify and leverage materials and design features that contribute to both objectives, creating efficient and multi-functional solutions.

Advanced Design Considerations and Material Choices

Beyond the core balance of cooling, noise reduction, and security, several other advanced design considerations play a crucial role in optimizing generator set enclosures. Material selection is paramount, influencing not only structural integrity and longevity but also thermal performance and acoustic properties. For instance, steel is commonly used for its strength and durability, but aluminum offers advantages in terms of weight and corrosion resistance, although it may require different structural design approaches. Composite materials are increasingly being used for their excellent sound dampening and thermal insulation properties, albeit often at a higher cost. Ventilation system design is another critical area, encompassing the size, placement, and type of vents, as well as the potential integration of fans or forced air cooling systems. Accessibility for maintenance and servicing is also a key consideration. Enclosures must be designed to allow easy access to the generator for routine checks, repairs, and component replacements. This often involves incorporating strategically placed doors, removable panels, and sufficient internal space for technicians to work safely and efficiently. Have you ever wondered how seemingly simple enclosures can incorporate so much intricate engineering? It’s in these details that the difference between a good and an exceptional enclosure lies.

Practical Examples and Real-World Applications

The principles of balanced enclosure design are applied across a wide range of generator set applications. In data centers, where uninterrupted power is critical, enclosures must provide robust security and highly effective cooling to ensure continuous operation. Noise reduction is also important, particularly in urban data center locations. Hospitals and healthcare facilities demand similar levels of reliability and security, with stringent noise regulations often in place. Residential generator installations prioritize noise reduction above all else, as homeowners seek quiet standby power solutions. Construction sites and remote industrial locations may place a greater emphasis on security and weather protection, while cooling remains a vital consideration, especially in hot climates. Marine applications require enclosures that are not only secure and provide cooling and noise reduction but are also resistant to harsh marine environments, including saltwater corrosion and extreme weather. These diverse applications highlight the need for adaptable and customizable enclosure designs, where the balance between cooling, noise reduction, and security is tailored to the specific operational requirements and environmental context. In my experience, understanding the intended application is the first and most crucial step in designing an effective generator set enclosure.

Interactive Questions: Engaging with Enclosure Design

Let's consider some interactive questions to further explore the complexities of generator set enclosure design. Firstly, how would you prioritize cooling, noise reduction, and security for a generator set intended for a residential area compared to one used in a remote mining operation? What specific design features would you emphasize in each scenario? Secondly, imagine you are tasked with designing an enclosure for a generator set operating in an extremely hot and dusty desert environment. What unique challenges would you anticipate, and how would you address them in your design to maintain optimal performance and longevity? These questions highlight the fact that there is no one-size-fits-all solution in enclosure design. The optimal balance between cooling, noise reduction, and security is always context-dependent, requiring careful consideration of the specific application, operating environment, and performance requirements. Thinking through these scenarios helps to appreciate the nuanced engineering decisions involved in creating effective generator set enclosures. Why is this approach so effective? Because it forces us to consider real-world constraints and trade-offs, moving beyond theoretical concepts to practical application.

Conclusion: Achieving the Optimal Balance

In conclusion, the design of a generator set enclosure is far from a simple task. It demands a sophisticated understanding of the interplay between cooling, noise reduction, and security, along with a keen awareness of the specific application and operating environment. Achieving the optimal balance between these three critical parameters is the key to creating enclosures that are not only functional and efficient but also reliable and long-lasting. By carefully considering material selection, ventilation strategies, noise attenuation techniques, and security measures, it is possible to design enclosures that meet the diverse needs of various generator set applications. Our company specializes in providing custom-engineered generator set enclosures that are designed to precisely balance cooling, noise reduction, and security requirements. We understand the intricacies of these design challenges and offer solutions tailored to meet the unique demands of each project. From initial concept to final installation, we are committed to delivering high-quality enclosures that ensure the optimal performance and protection of your generator sets.

For more detailed information, please visit our official website: Generator set enclosure