Mining operations, by their very nature, are often located in remote and challenging environments. Access to a stable and reliable power supply is absolutely crucial for maintaining productivity, ensuring safety, and minimizing downtime. However, connecting to the main power grid isn't always feasible or economically viable. This is where containerized power generators become an indispensable asset. These self-contained units offer a flexible, robust, and easily deployable solution for meeting the demanding energy needs of mining sites. They provide a localized power source, allowing mining companies to operate efficiently regardless of their location's grid connectivity. They can power everything from heavy machinery and processing plants to on-site accommodation and communication systems.

The Advantages of Containerized Power Generation

The advantages of utilizing containerized power generators in mining extend far beyond simply providing electricity. Consider the logistical benefits. The containerized design allows for easy transportation via truck, train, or even ship. This is particularly important for mines located in remote areas with limited infrastructure. They can be quickly deployed and relocated as the mining operation evolves. Furthermore, the robust construction of these containers protects the generator from harsh weather conditions, dust, and other environmental factors commonly found at mining sites. This protection extends the lifespan of the generator and reduces the need for frequent maintenance. Wouldn't you agree that having a power source that is both mobile and durable is a significant advantage in such a demanding environment?

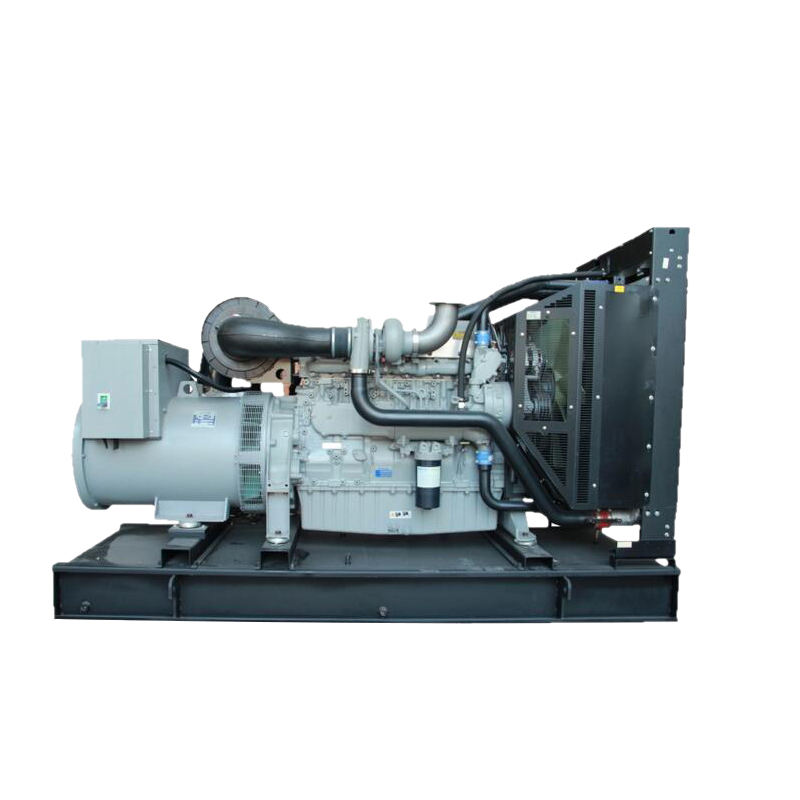

Types of Containerized Generators Used in Mining

There are various types of containerized power generators suitable for mining applications, each with its own set of characteristics and suitability. Diesel generators are perhaps the most common, known for their reliability and fuel efficiency, particularly in high-load situations. Natural gas generators offer a cleaner-burning alternative, especially if a natural gas pipeline is accessible near the mining site. Biogas generators, utilizing gas produced from organic waste, present a more sustainable option where applicable. Hybrid systems, which combine diesel or gas generators with renewable energy sources like solar or wind, are gaining traction, offering a balance between reliability and environmental responsibility. The choice of generator depends on several factors, including fuel availability, environmental regulations, power requirements, and budget constraints. Which of these options do you think would best suit the specific needs of your mining operation, and why?

Fuel Efficiency and Operational Costs

Fuel consumption is a significant operating expense for mining operations relying on containerized generators. Optimizing fuel efficiency is therefore paramount. Regular maintenance, including filter replacements and engine tuning, plays a crucial role in maintaining peak performance. Furthermore, selecting the appropriate generator size for the actual power demand is essential. Oversizing a generator can lead to inefficient operation and increased fuel consumption. Implementing load management strategies, such as prioritizing power usage and staggering equipment startup times, can also reduce overall fuel consumption. Smart controls and monitoring systems can provide real-time data on fuel usage and generator performance, allowing for proactive adjustments and optimization. These systems can also detect potential problems early on, preventing costly breakdowns and downtime.

Environmental Considerations

Mining operations are often subject to strict environmental regulations, and power generation is a key area of focus. While containerized generators offer a convenient power solution, it's crucial to minimize their environmental impact. This can be achieved through several strategies. Using cleaner-burning fuels like natural gas or biogas can significantly reduce emissions. Installing exhaust after-treatment systems, such as selective catalytic reduction (SCR) or diesel particulate filters (DPF), can further minimize pollutants. Implementing noise reduction measures, such as soundproofing the container and using noise barriers, can help mitigate noise pollution. Proper disposal of waste oil and other hazardous materials is also essential. Increasingly, mining companies are exploring hybrid systems that incorporate renewable energy sources to reduce their reliance on fossil fuels.

Case Studies: Successful Implementation

Several mining companies have successfully implemented containerized power generators to improve their operations. For example, a gold mine in a remote region of South America replaced its unreliable grid connection with a fleet of containerized diesel generators. This resulted in a significant increase in productivity and a reduction in downtime. A copper mine in Australia implemented a hybrid system combining diesel generators with a large-scale solar array. This reduced their fuel consumption by over 30% and significantly lowered their carbon footprint. In another instance, a coal mine in Indonesia utilized containerized natural gas generators to power its operations, taking advantage of the readily available natural gas resources in the region. These examples demonstrate the versatility and effectiveness of containerized power generators in various mining contexts.

Maintenance and Longevity

Proper maintenance is key to maximizing the lifespan and reliability of containerized power generators. Establishing a regular maintenance schedule, including routine inspections, oil changes, filter replacements, and engine tuning, is essential. Keeping detailed records of maintenance activities can help identify potential problems early on. Investing in high-quality replacement parts can also improve the long-term performance of the generator. Training on-site personnel to perform basic maintenance tasks can reduce reliance on external service providers and minimize downtime. Remote monitoring systems can provide real-time data on generator performance, allowing for proactive maintenance and troubleshooting. Addressing minor issues promptly can prevent them from escalating into major problems, extending the lifespan of the generator and minimizing costly repairs.

Future Trends in Containerized Power Generation for Mining

The future of containerized power generation in mining is likely to be shaped by several key trends. Increased adoption of renewable energy sources, such as solar and wind, will drive the development of more sophisticated hybrid systems. Battery storage technology will play an increasingly important role in smoothing out the intermittency of renewable energy and providing backup power. Advancements in generator technology will lead to more fuel-efficient and lower-emission engines. Remote monitoring and control systems will become more sophisticated, providing real-time data and enabling proactive maintenance. The integration of artificial intelligence and machine learning will further optimize generator performance and predict potential failures. As mining operations continue to push into more remote and challenging environments, containerized power generators will remain a crucial enabler of sustainable and efficient resource extraction.

Cost-Effectiveness and ROI

While the initial investment in containerized power generators may seem significant, it's important to consider the long-term cost-effectiveness and return on investment (ROI). By providing a reliable and stable power supply, these generators can significantly reduce downtime and increase productivity. This can lead to a substantial increase in revenue. Furthermore, using fuel-efficient generators and implementing load management strategies can minimize fuel consumption and reduce operating costs. In some cases, the savings from reduced downtime and fuel consumption can offset the initial investment within a few years. Additionally, the ability to relocate the generator to different mining sites as needed provides added flexibility and value. Ultimately, the ROI of containerized power generators depends on several factors, including the specific power requirements of the mining operation, the cost of fuel, and the frequency of use. But in many cases, the benefits far outweigh the costs.

In conclusion, containerized power generators for mining sites represent a vital solution for ensuring reliable and efficient power in remote and demanding environments. Their portability, robustness, and adaptability make them ideal for powering diverse mining operations. As technology continues to evolve, these generators will become even more efficient, environmentally friendly, and cost-effective, solidifying their role as a cornerstone of modern mining practices.