OEM generator manufacturing, or Original Equipment Manufacturer generator manufacturing, signifies a specialized field within the power generation industry. It involves a company (the OEM) designing and producing generators which are then branded and sold by another company. Essentially, one company handles the complexities of design, engineering, and production, while the other focuses on marketing, sales, and distribution. This symbiotic relationship allows companies to expand their product offerings without the significant capital investment and specialized expertise required to establish their own generator manufacturing facilities. Think of it like a white-label product, but on a much larger, more complex scale. The core of OEM generator manufacturing lies in building generators to the specific requirements and branding of the partnering company, allowing them to enter the generator market with a product carrying their name and reputation.

Understanding the OEM Generator Manufacturing Process

The OEM generator manufacturing process typically begins with a detailed consultation between the company seeking to sell generators under their brand (the client) and the OEM. This consultation involves defining the specifications of the generator, including power output, engine type, fuel type (diesel, gasoline, natural gas, etc.), features (such as automatic transfer switches or digital control panels), and any unique design elements. Once the specifications are agreed upon, the OEM’s engineering team develops a detailed design and prototype. This prototype is rigorously tested to ensure it meets the performance requirements and safety standards. If the client approves the prototype, the OEM proceeds with manufacturing the generators in bulk. Quality control is a crucial aspect of this process, with inspections conducted at various stages to ensure that each generator meets the agreed-upon specifications and functions reliably. This entire process demands a high degree of coordination and communication between the OEM and the client.

Consider a well-known outdoor equipment retailer that desires to offer a line of generators under its own brand. Instead of investing heavily in building its own generator manufacturing plant, the retailer partners with an experienced OEM generator manufacturer. The retailer provides the desired specifications for the generators, including the target power output, fuel type (gasoline), and features (such as multiple outlets and portability). The OEM designs and manufactures the generators according to these specifications, applying the retailer's branding and logo to the finished product. The retailer then sells these generators through its retail stores and online channels, benefiting from the OEM's manufacturing expertise without the associated capital investment.

Benefits of Partnering with an OEM Generator Manufacturer

The advantages of working with an OEM generator manufacturer are numerous. Primarily, it drastically reduces capital expenditure. Building a generator manufacturing facility requires significant investment in equipment, infrastructure, and personnel. Partnering with an OEM eliminates these costs, allowing the client company to allocate resources to other areas such as marketing, sales, and customer service. Furthermore, OEMs possess specialized expertise in generator design, engineering, and manufacturing. This expertise ensures that the generators are of high quality and meet the required performance standards. Clients benefit from this expertise without needing to hire and train their own specialized team. This access to specialized knowledge is invaluable, particularly for companies new to the generator market.

Another crucial benefit is the reduction in time-to-market. Developing and manufacturing generators from scratch can be a lengthy process. By partnering with an OEM, clients can significantly reduce the time it takes to bring their branded generators to market. The OEM already has the infrastructure, processes, and expertise in place to efficiently manufacture generators, allowing the client to quickly capitalize on market opportunities. Also, consider the advantages when it comes to economies of scale. OEM manufacturers often produce generators in large volumes for multiple clients, allowing them to achieve economies of scale that can result in lower production costs. These cost savings can be passed on to the client, making their branded generators more competitive in the market.

Factors to Consider When Choosing an OEM Generator Manufacturer

Selecting the right OEM generator manufacturer is crucial for the success of your branded generator program. Several factors need careful consideration. Firstly, the OEM's experience and reputation in the industry are paramount. Look for an OEM with a proven track record of producing high-quality generators that meet industry standards. Examine their past projects, client testimonials, and industry certifications. Secondly, assess the OEM's manufacturing capabilities and capacity. Ensure that they have the equipment, infrastructure, and personnel to handle the volume of generators you require. In addition, the OEM's commitment to quality control is essential. Look for an OEM that has robust quality control processes in place at every stage of the manufacturing process.

Beyond these fundamental factors, you must evaluate the OEM's design and engineering capabilities. A strong design and engineering team can help you develop innovative and customized generator solutions that meet your specific needs. Consider their ability to adapt to your unique branding requirements. Can the OEM incorporate your branding elements seamlessly into the generator design? Also, clear and open communication is vital for a successful partnership. Choose an OEM that is responsive, communicative, and willing to work collaboratively with you throughout the entire process. What happens if issues arise during manufacturing or after the generators are in the market? Ensure they have a robust after-sales service and support network to address any issues that may arise. This demonstrates their commitment to customer satisfaction and ensures the long-term success of your branded generator program.

Types of Generators Commonly Manufactured by OEMs

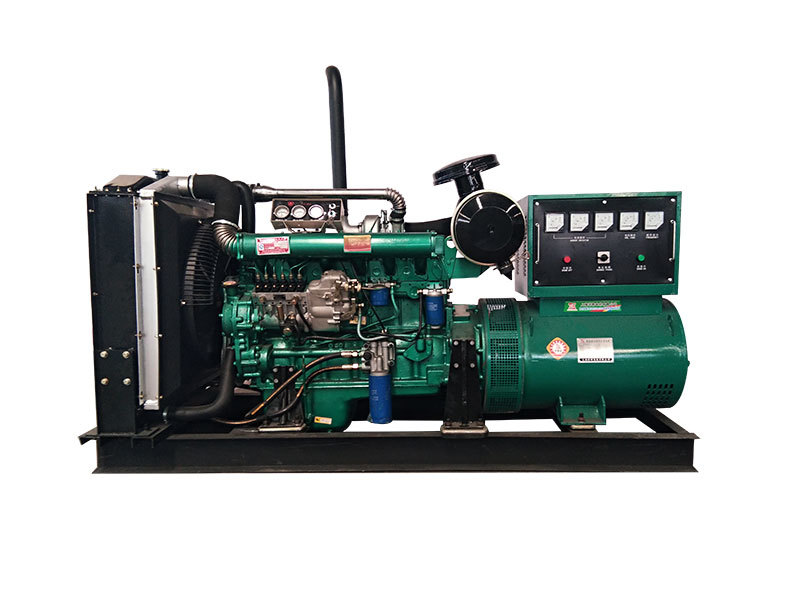

OEM generator manufacturers produce a wide range of generators to cater to diverse applications and power requirements. Portable generators are a popular choice for homeowners, campers, and construction workers who need a reliable source of power on the go. These generators are typically powered by gasoline and are designed to be lightweight and easy to transport. In addition, standby generators are designed to automatically provide backup power during power outages. These generators are typically powered by natural gas or propane and are permanently installed outside a home or business. They are crucial for maintaining essential services such as lighting, heating, and cooling during emergencies.

Beyond residential and commercial applications, industrial generators are designed to provide power for heavy-duty equipment and machinery in industrial settings. These generators are typically powered by diesel and are built to withstand harsh operating conditions. There are also inverter generators, which produce cleaner and more stable power than traditional generators. These generators are ideal for powering sensitive electronics such as computers and smartphones. Furthermore, PTO (Power Take-Off) generators are driven by the power take-off shaft of a tractor or other agricultural equipment. These generators are commonly used in rural areas where access to grid power is limited. The versatility of OEM manufacturers allows for a broad spectrum of generator types to be produced under different brands.

Quality Control in OEM Generator Manufacturing

Rigorous quality control is an integral part of OEM generator manufacturing. From the initial design phase to the final product assembly, every step is carefully monitored and inspected to ensure that the generators meet the required performance standards and safety regulations. This involves a comprehensive testing process that includes performance testing, safety testing, and durability testing. Performance testing verifies that the generator produces the specified power output and operates efficiently. Safety testing ensures that the generator meets all safety standards and regulations, such as those related to electrical safety and emissions. Durability testing assesses the generator's ability to withstand harsh operating conditions and maintain its performance over time.

The quality control process also includes thorough inspections of all components and materials used in the generator's construction. This helps to identify any defects or non-conformities before they can impact the generator's performance or reliability. Furthermore, many OEM manufacturers utilize statistical process control (SPC) techniques to monitor and control the manufacturing process. SPC involves collecting and analyzing data to identify trends and patterns that may indicate potential problems. By identifying these problems early, manufacturers can take corrective action to prevent defects and improve the overall quality of their generators. A generator failure can be catastrophic, so redundancy in quality control is critical to maintain reputation and avoid liability.

The Future of OEM Generator Manufacturing

The future of OEM generator manufacturing is likely to be shaped by several key trends. Increased demand for backup power solutions due to extreme weather events and an aging power grid will drive growth in the generator market. As power outages become more frequent and prolonged, the need for reliable backup power will continue to increase. Advances in generator technology, such as more efficient engines, cleaner emissions, and smart grid integration, will also influence the industry. This includes the development of generators that can operate on renewable fuels such as biodiesel and biogas, which can help to reduce carbon emissions. Also, the integration of generators with smart grids will enable more efficient and reliable power distribution.

Customization and personalization will become increasingly important as clients seek to differentiate their branded generators from the competition. OEM manufacturers will need to offer more flexible design and manufacturing options to meet these demands. Supply chain resilience is becoming an increasingly important consideration. The COVID-19 pandemic highlighted the vulnerabilities of global supply chains, and OEM manufacturers will need to develop more robust and diversified supply chains to mitigate these risks. Finally, sustainability will be a major focus, with manufacturers adopting more environmentally friendly materials and processes. The focus must shift towards efficiency and eco-friendliness to attract future clients.

OEM Generator Manufacturing: A Strategic Advantage

In conclusion, OEM generator manufacturing offers a strategic advantage for companies looking to enter or expand their presence in the power generation market. By partnering with an experienced OEM manufacturer, companies can avoid the significant capital investment and specialized expertise required to establish their own manufacturing facilities. This allows them to focus on their core competencies, such as marketing, sales, and customer service. Choosing the right OEM partner, with robust quality control, adaptability, and a focus on future trends is paramount. By making a well-informed decision, your organization can successfully leverage the power of OEM generator manufacturing to achieve market success and build a strong brand reputation.

Considering the intricacies of OEM generator manufacturing, what specific features or functionalities would you prioritize when selecting a manufacturer for a line of residential standby generators? Furthermore, how important is the manufacturer's commitment to sustainability and environmental responsibility in your decision-making process?

`