The mining industry, by its very nature, demands a constant and reliable source of power. From operating heavy machinery deep within the earth to powering ventilation systems and processing plants on the surface, the availability of electricity is not merely a convenience, but a fundamental requirement for safe and efficient operations. Without a stable power supply, mining activities grind to a halt, leading to significant financial losses, safety hazards, and potential environmental consequences. Therefore, the selection and implementation of appropriate mining industry power generators are paramount.

The Critical Role of Power Generators in Mining Operations

Mining sites are often located in remote and geographically challenging areas, far from established power grids. Extending existing grid infrastructure to these locations can be prohibitively expensive and time-consuming. Furthermore, relying solely on the grid carries the risk of power outages due to weather events, grid failures, or other unforeseen circumstances. Mining industry power generators provide a crucial source of on-site power, ensuring operational continuity regardless of external factors. They allow mines to operate independently and maintain consistent production levels, maximizing profitability and minimizing downtime. The use of these generators extends beyond simple operational necessities; they directly impact the safety of the miners working within, ensuring adequate ventilation, lighting, and communication systems remain functional, even during grid failures or emergencies.

Types of Power Generators Used in Mining

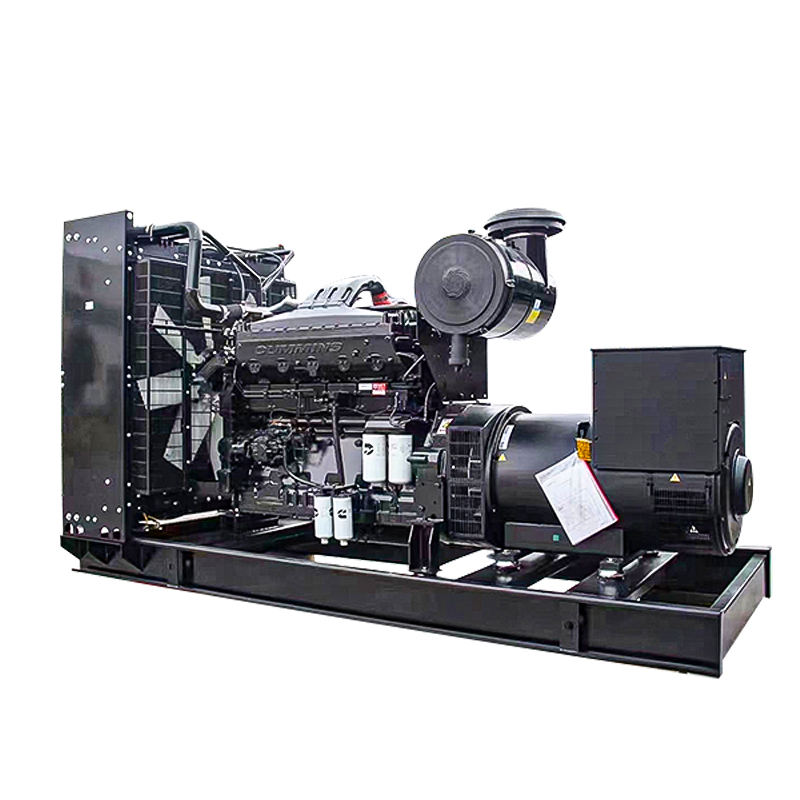

A wide array of power generator technologies are deployed in the mining industry, each with its own set of advantages and disadvantages. Diesel generators are perhaps the most prevalent, offering a proven track record of reliability and readily available fuel supplies. However, diesel engines are also associated with higher emissions and fuel costs compared to alternative options. Natural gas generators present a cleaner-burning alternative, particularly in regions with abundant natural gas resources. Their emissions profile is generally lower than diesel, and fuel costs can be more competitive. Renewable energy sources, such as solar and wind power, are also gaining traction in the mining industry, often integrated with battery storage systems to provide a more sustainable and cost-effective power solution. Hybrid systems, combining different generator types, are becoming increasingly common, allowing mines to optimize their power supply based on factors such as fuel availability, environmental regulations, and cost considerations. Mining industry power generators are evolving to meet the challenges of a rapidly changing world.

Factors Influencing Generator Selection for Mining

Choosing the right power generator for a specific mining operation requires careful consideration of several key factors. Power requirements, including peak demand and load profiles, must be accurately assessed to ensure the generator can meet the mine's electricity needs. Fuel availability and costs play a significant role in determining the long-term operating expenses of the power system. Environmental regulations and emission standards are becoming increasingly stringent, requiring mines to adopt cleaner generator technologies or implement emission control measures. The location of the mine also influences generator selection. High-altitude environments, for example, may require specialized generator designs to compensate for reduced air density. The initial investment cost of the generator, along with ongoing maintenance and operating expenses, must be factored into the overall economic analysis. Have you considered all of these factors when thinking about your power needs?

Fuel Options for Mining Power Generators

The choice of fuel for mining industry power generators has a significant impact on operational costs, environmental footprint, and overall sustainability. Diesel fuel remains a popular option due to its high energy density and widespread availability. However, the rising cost of diesel and increasing environmental concerns are driving interest in alternative fuels. Natural gas offers a cleaner-burning alternative to diesel, producing lower emissions and potentially reducing fuel costs. Liquefied natural gas (LNG) is particularly attractive for remote mining sites where pipeline infrastructure is limited. Renewable energy sources, such as solar and wind power, can be integrated into the power system to reduce reliance on fossil fuels and lower carbon emissions. Biogas, produced from organic waste materials, offers another sustainable fuel option for mining operations located near agricultural or industrial facilities. The selection of the optimal fuel depends on factors such as fuel availability, cost, emissions regulations, and the mine's commitment to sustainability.

Maintenance and Reliability of Mining Power Generators

Maintaining the reliability of mining industry power generators is crucial for ensuring uninterrupted mining operations. Regular maintenance, including inspections, lubrication, and component replacements, is essential for preventing breakdowns and extending the lifespan of the generator. Proper maintenance procedures should be followed according to the manufacturer's recommendations. Remote monitoring systems can be used to track generator performance, detect potential problems early, and schedule maintenance activities proactively. A well-trained maintenance team is critical for performing routine maintenance, troubleshooting issues, and carrying out repairs. A comprehensive maintenance program, combined with proactive monitoring and skilled personnel, can significantly improve the reliability and availability of mining power generators, minimizing downtime and maximizing operational efficiency.

Power Generator Control and Automation in Mining

Advanced control and automation systems play a crucial role in optimizing the performance and efficiency of mining industry power generators. These systems can automatically start and stop generators based on load demand, optimizing fuel consumption and reducing emissions. Load sharing capabilities allow multiple generators to operate in parallel, providing redundancy and ensuring a stable power supply. Remote monitoring and control features enable operators to monitor generator performance, adjust settings, and troubleshoot issues from a central location. Programmable logic controllers (PLCs) can be used to automate various generator functions, such as voltage regulation, frequency control, and safety shutdown procedures. Automation systems can also integrate with other mine systems, such as ventilation and pumping systems, to optimize overall energy usage and improve operational efficiency. This level of integrated control is increasingly important in modern mining operations.

Case Studies: Successful Power Generator Implementations in Mining

Several mining companies have successfully implemented innovative power generator solutions to improve operational efficiency, reduce costs, and enhance sustainability. One example involves a gold mine in a remote location that implemented a hybrid power system consisting of diesel generators, solar panels, and battery storage. This solution reduced the mine's reliance on diesel fuel, lowered carbon emissions, and improved the reliability of the power supply. Another case study involves a copper mine that installed a natural gas generator powered by LNG. This allowed the mine to access a cleaner and more cost-effective fuel source, reducing operating expenses and improving environmental performance. Yet another example involves a coal mine that implemented a waste heat recovery system to capture waste heat from the generators and use it to generate additional electricity. These case studies demonstrate the potential for mining industry power generators to deliver significant benefits in terms of cost savings, environmental sustainability, and operational efficiency.

Future Trends in Mining Industry Power Generation

The future of mining industry power generators is likely to be shaped by several key trends. The increasing demand for cleaner and more sustainable energy sources will drive the adoption of renewable energy technologies and alternative fuels. Advances in battery storage technology will enable greater integration of renewable energy into the power system, reducing reliance on fossil fuels. The development of more efficient and reliable generator technologies, such as solid oxide fuel cells (SOFCs), will offer further opportunities to reduce emissions and improve fuel efficiency. The use of advanced control and automation systems will continue to grow, enabling more efficient and optimized operation of power generators. Finally, the integration of power generators with other mine systems, such as ventilation and pumping systems, will lead to more holistic energy management and improved overall operational efficiency. The mining industry is actively embracing these future trends to secure a sustainable and cost-effective energy future.

Conclusion: Powering the Future of Mining

In conclusion, mining industry power generators are indispensable for ensuring the continuous and reliable operation of mining activities. The selection of the right generator technology, fuel source, and control system is critical for optimizing operational efficiency, reducing costs, and minimizing environmental impact. As the mining industry evolves, the adoption of cleaner and more sustainable power solutions will become increasingly important. By embracing innovation and investing in advanced power generator technologies, mining companies can ensure a sustainable and prosperous future. The crucial role that these generators play cannot be overstated in achieving both the financial and ethical goals of the modern mining operation.

`