Generator sets, the unsung heroes of backup power and continuous electricity supply in countless industries, come in various shapes and sizes, and employ different cooling mechanisms. Among these, water cooled generator sets stand out for their efficiency, reliability, and suitability for demanding applications. Understanding how these systems work, their benefits, and where they excel is crucial for making informed decisions about power generation solutions. Let's delve into the world of water cooled generators and explore what makes them a preferred choice in many scenarios.

Understanding Water Cooled Generator Sets

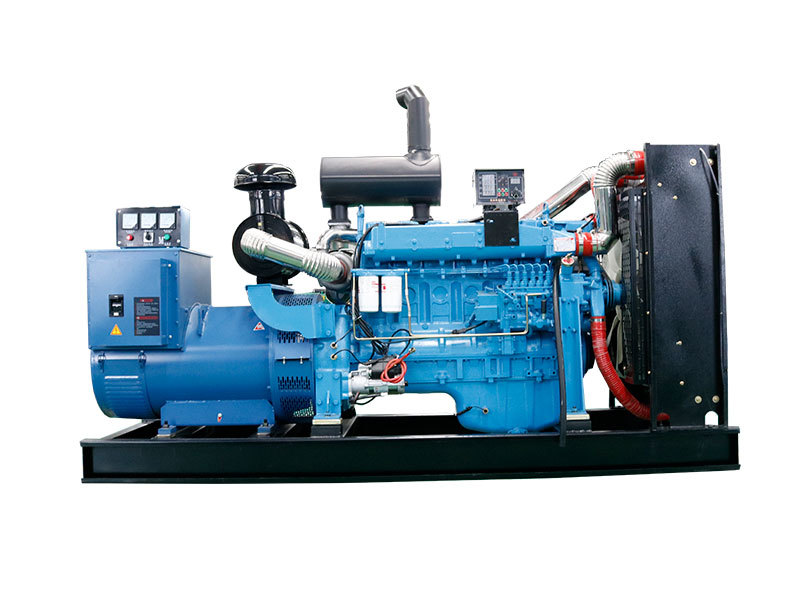

At its core, a water cooled generator set functions much like any other generator: it converts mechanical energy into electrical energy through electromagnetic induction. The difference lies in how the engine, the source of mechanical energy, is kept from overheating. Instead of relying solely on air to dissipate heat, a water cooled system employs a liquid coolant – typically a mixture of water and antifreeze – that circulates through the engine block. This coolant absorbs heat and transports it to a radiator, where fans force air across the radiator's fins, dissipating the heat into the atmosphere. This closed-loop system ensures efficient temperature regulation, even under prolonged and heavy loads. It's a bit like the cooling system in your car, scaled up and optimized for continuous operation. The effectiveness of this method hinges on factors like the coolant mixture, radiator size, fan capacity, and overall system design.

Advantages of Water Cooling

The adoption of water cooling in generator sets brings with it a multitude of benefits compared to their air-cooled counterparts. First and foremost is superior thermal management. Water, having a higher heat capacity than air, can absorb and transport heat much more effectively. This allows water cooled generators to operate at consistently lower temperatures, even when subjected to high loads for extended periods. Lower operating temperatures translate directly into improved engine longevity and reduced maintenance requirements. Secondly, water cooled generators tend to be quieter in operation. The engine block, surrounded by coolant, acts as a sound dampener, reducing noise pollution. This is particularly advantageous in environments where noise levels are a concern, such as residential areas or hospitals. Finally, these generators are often more fuel-efficient due to the consistent engine temperature, leading to improved combustion and reduced fuel consumption over time. Isn't it compelling to consider the long-term cost savings associated with these advantages?

Applications Across Industries

The robust nature and reliable performance of water cooled generator sets make them suitable for a wide range of applications across various industries. In data centers, where uninterrupted power is paramount, these generators provide critical backup power to prevent data loss and maintain operations during grid outages. Hospitals also rely heavily on water cooled generator sets to ensure continuous operation of life-support systems and other essential equipment. The reduced noise levels are an added benefit in these sensitive environments. Industrial manufacturing plants frequently use them for both prime power (continuous electricity supply) and backup power, especially in areas where the grid is unreliable. Furthermore, large-scale construction projects often employ water cooled generators to power equipment and machinery on-site. They are also widely used in telecommunications, mining operations, and offshore oil and gas platforms, where reliable power is essential for critical operations. These examples highlight the versatility and importance of water cooled generators in diverse and demanding settings.

Key Components of a Water Cooled System

A typical water cooled generator set comprises several key components working in concert to ensure efficient operation. The engine, the heart of the system, is responsible for converting fuel into mechanical energy. The radiator serves as the primary heat exchanger, dissipating heat from the coolant into the atmosphere. The water pump circulates the coolant throughout the system, ensuring continuous heat transfer. The thermostat regulates coolant flow to maintain optimal engine temperature. The cooling fan forces air across the radiator fins to enhance heat dissipation. Coolant hoses and pipes connect all these components, forming a closed loop. The control panel monitors various parameters, such as coolant temperature, oil pressure, and voltage output, providing critical information for system operation and maintenance. Understanding the function of each component is essential for effective troubleshooting and maintenance.

Maintenance and Longevity

While water cooled generator sets are renowned for their reliability, regular maintenance is crucial to ensure optimal performance and extend their lifespan. Key maintenance tasks include checking and maintaining the correct coolant level and mixture, inspecting hoses and connections for leaks, cleaning the radiator fins to ensure proper airflow, and replacing the coolant at recommended intervals. Regular oil changes are also essential for engine health. Additionally, it is important to monitor the system for any signs of overheating, such as excessive coolant temperature or steam leaks. Keeping a detailed maintenance log can help track performance and identify potential issues early on. Investing in preventative maintenance not only minimizes the risk of unexpected downtime but also significantly extends the operational life of the generator set. Do you have a plan for routine maintenance and inspections?

Comparing Water Cooling to Air Cooling

The choice between water cooled and air cooled generator sets often depends on the specific application and requirements. Air cooled generators are generally simpler in design and require less maintenance, making them a suitable option for smaller, less demanding applications. However, they are less efficient at dissipating heat, making them less suitable for prolonged operation under heavy loads. Water cooled generators, on the other hand, offer superior thermal management and are better suited for demanding applications where continuous, reliable power is critical. They are also quieter in operation and tend to be more fuel-efficient. While water cooled generators may have a higher initial cost and require more maintenance, their long-term benefits often outweigh these considerations, particularly in industries where downtime is costly and reliability is paramount. Thinking about your long-term operational needs can guide this decision process.

Factors to Consider When Choosing a Water Cooled Generator Set

Selecting the right water cooled generator set requires careful consideration of several factors. First, power requirements must be accurately assessed to ensure the generator can handle the intended load. Consider both the continuous power demand and any peak loads that may occur. Next, environmental conditions play a significant role. Generators operating in harsh environments, such as extreme temperatures or high humidity, may require additional protection and specialized cooling systems. The fuel type (diesel, natural gas, or propane) should be selected based on availability, cost, and regulatory requirements. Noise levels should be considered, particularly in noise-sensitive environments. Finally, maintenance requirements and the availability of qualified service technicians should be factored into the decision-making process. A thorough evaluation of these factors will help ensure that the selected generator set meets your specific needs and provides reliable power for years to come.

Future Trends in Water Cooled Generator Technology

The field of water cooled generator technology is constantly evolving, driven by the need for increased efficiency, reduced emissions, and improved reliability. One emerging trend is the development of more efficient cooling systems that utilize advanced materials and innovative designs to enhance heat transfer. Another trend is the integration of smart control systems that optimize generator performance based on real-time data and predictive analytics. These systems can monitor engine parameters, detect potential problems, and automatically adjust settings to maximize efficiency and minimize downtime. Furthermore, there is a growing emphasis on reducing emissions through the use of advanced combustion technologies and alternative fuels. As environmental regulations become more stringent, manufacturers are investing in research and development to create cleaner and more sustainable generator sets. These advancements promise to further enhance the performance and reliability of water cooled generators in the years to come.

Water Cooled Generators and Sustainability

In today's world, sustainability is an increasingly important consideration, and water cooled generator sets are playing a role in promoting environmentally responsible power generation. While generators that rely on fossil fuels will always have an environmental impact, modern water cooled models are designed for maximum fuel efficiency, reducing overall emissions. Furthermore, some manufacturers are exploring the use of alternative fuels, such as biodiesel and renewable natural gas, which can significantly reduce the carbon footprint of generator operation. The extended lifespan of water cooled generators, due to their superior thermal management, also contributes to sustainability by reducing the need for frequent replacements. Moreover, properly maintained cooling systems minimize coolant leakage, preventing environmental contamination. As technology continues to advance, we can expect to see further innovations that enhance the sustainability of water cooled generator sets, making them a more environmentally conscious choice for reliable power generation.

Conclusion

Water cooled generator sets stand as a reliable and efficient solution for diverse power generation needs. From critical backup systems in hospitals and data centers to prime power sources in industrial plants, their ability to maintain stable operating temperatures under demanding conditions sets them apart. The advantages of enhanced thermal management, reduced noise, and often improved fuel efficiency make them a preferred choice where consistent and dependable power is paramount. By understanding the intricacies of their operation, the importance of regular maintenance, and the factors influencing selection, users can leverage the full potential of water cooled generator sets to meet their specific power requirements and contribute to a more sustainable future.