The hum of machinery, the methodical movements of workers, and the unmistakable scent of metal and electricity – these are the hallmarks of a single phase generators factory. More than just a building, it's a complex ecosystem where raw materials transform into essential power solutions for homes, small businesses, and specialized applications. Understanding what goes on inside these factories, the processes involved, and the factors that contribute to their success is crucial for anyone looking to purchase, maintain, or even innovate in the field of single phase power generation. What exactly defines a 'single phase' generator and why are they so ubiquitous?

Understanding the Production Process

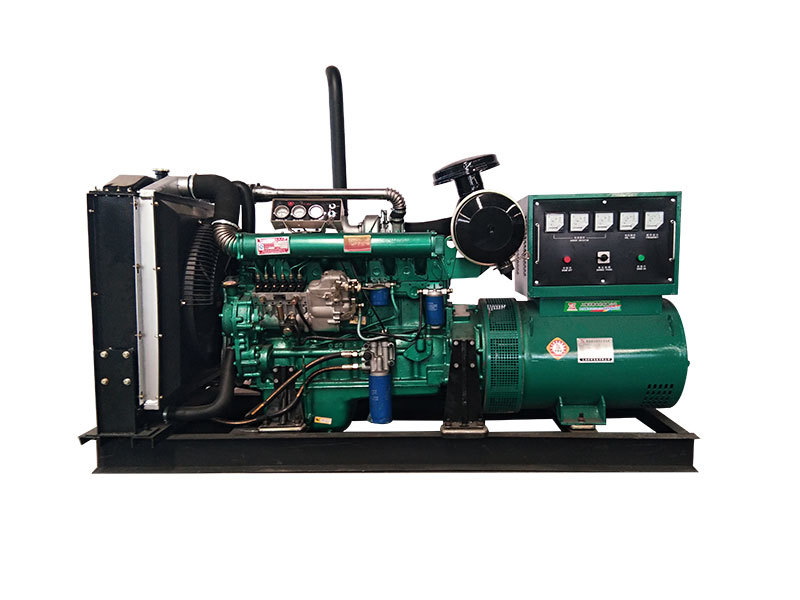

The journey of a single phase generator from conception to completion is a multi-stage process. It all begins with design and engineering. Skilled engineers use CAD software and intricate calculations to create detailed blueprints for each generator model. These blueprints specify everything from the precise dimensions of the stator and rotor to the wiring configuration and control panel layout. Material selection is also paramount. High-quality copper windings, durable steel for the frame and core, and robust components for the engine or motor are critical for longevity and performance. Purchasing departments source these materials from trusted suppliers, often working under strict quality control protocols. Once the materials are in-house, the manufacturing process begins in earnest. This typically involves machining, winding, assembly, and rigorous testing.

The core of the generator, the stator and rotor, are often produced using automated winding machines and precision machining tools. Coils of copper wire are carefully wound around the stator core, creating the electromagnetic field that will generate electricity. The rotor, which rotates within the stator, is similarly constructed with precision balancing to minimize vibration during operation. These components are then meticulously assembled, a process that often combines automated processes with skilled manual labor. Wiring harnesses are connected, control panels are installed, and the entire unit is mounted on a sturdy frame. This assembly phase requires meticulous attention to detail to ensure that all components are properly connected and functioning correctly. Consider the complexity of ensuring perfect insulation to prevent short circuits and ensure safe operation. Have you ever considered the sheer volume of individual connections within a single generator?

Quality Control and Testing

A single phase generators factory isn't just about mass production; it's about quality assurance. Rigorous testing procedures are implemented at every stage of the manufacturing process. Individual components are tested for defects before assembly. Partially assembled units undergo intermediate tests to identify potential problems early on. Finally, fully assembled generators are subjected to a battery of tests that simulate real-world operating conditions. These tests may include load testing, voltage regulation testing, frequency stability testing, and insulation resistance testing. Generators that fail to meet the required standards are either reworked or rejected entirely. This commitment to quality control is what separates reputable manufacturers from those who prioritize quantity over quality. Look for certifications like ISO 9001, which demonstrate a commitment to quality management systems. What specific types of testing would *you* prioritize if you were in charge of quality control?

Customization and Specialization

While some single phase generators factories focus on producing standardized models, others specialize in customization. They cater to customers with unique power requirements, such as those in the telecommunications industry, the medical field, or remote construction sites. Customization can involve modifying the generator's power output, voltage, frequency, or enclosure design. It might also involve integrating specialized features, such as automatic transfer switches (ATS) or remote monitoring systems. Factories that offer customization often have dedicated engineering teams that work closely with customers to understand their specific needs and develop tailored solutions. This level of service requires a high degree of technical expertise and flexibility. The ability to adapt to changing customer demands is a key competitive advantage in the single phase generator market. How critical is customization when choosing a generator for a specific application?

Supply Chain Management

The efficient operation of a single phase generators factory relies heavily on effective supply chain management. The factory needs to ensure a steady supply of raw materials and components, while minimizing inventory costs and lead times. This requires close collaboration with suppliers, sophisticated inventory management systems, and efficient logistics. Many factories use ERP (Enterprise Resource Planning) systems to track materials, manage production schedules, and coordinate deliveries. They also employ lean manufacturing principles to eliminate waste and improve efficiency throughout the supply chain. Disruptions in the supply chain, such as those caused by natural disasters or geopolitical events, can have a significant impact on a factory's ability to meet its production targets. Therefore, risk management is an essential part of supply chain management in this industry. Considering the global nature of supply chains, how can factories mitigate risks and ensure a consistent flow of materials?

The Role of Technology

Technology plays an increasingly important role in single phase generators factories. Automation, robotics, and computer-aided design (CAD) and manufacturing (CAM) are all being used to improve efficiency, reduce costs, and enhance product quality. Automated winding machines, robotic assembly lines, and laser cutting machines are just a few examples of the technologies being adopted. These technologies can help to increase production speed, reduce human error, and improve the consistency of the finished product. Furthermore, advanced diagnostic tools and monitoring systems are being used to improve maintenance and prevent breakdowns. The integration of Internet of Things (IoT) technologies is also enabling remote monitoring and control of generators, providing valuable data for performance analysis and predictive maintenance. What innovative technologies do you foresee further transforming generator manufacturing in the future?

Environmental Considerations

Modern single phase generators factories are increasingly focused on environmental sustainability. They are implementing measures to reduce energy consumption, minimize waste, and control emissions. This may involve using energy-efficient equipment, recycling materials, and implementing closed-loop water systems. Some factories are also investing in renewable energy sources, such as solar panels, to power their operations. Furthermore, they are developing new generator designs that are more fuel-efficient and produce fewer emissions. Compliance with environmental regulations is also a major concern. Factories must adhere to strict standards for air and water quality, as well as for the disposal of hazardous waste. The pressure to reduce environmental impact is driving innovation and creating new opportunities for manufacturers who are committed to sustainability. What incentives could further encourage "green" manufacturing practices in the single phase generator industry?

Choosing the Right Generator Factory

For businesses seeking to purchase single phase generators, selecting the right factory is crucial. Consider several key factors. First, assess the factory's reputation and track record. Look for certifications, customer testimonials, and case studies. Second, evaluate the factory's product range and capabilities. Does it offer the specific type of generator you need, and can it customize generators to meet your unique requirements? Third, compare prices and lead times. Get quotes from multiple factories and ask about their production capacity and delivery schedules. Fourth, consider the factory's quality control procedures. Ask about their testing methods and their commitment to quality assurance. Finally, consider the factory's customer service and support. Do they offer technical support, warranty services, and spare parts? By carefully evaluating these factors, you can choose a single phase generators factory that will provide you with high-quality, reliable power solutions. How important is a strong warranty and after-sales support when purchasing a generator?

The Future of Single Phase Generator Manufacturing

The single phase generators factory of the future will be characterized by increased automation, greater customization, and a stronger focus on sustainability. Advanced robotics, artificial intelligence, and 3D printing will be used to streamline production processes, reduce costs, and create more complex and customized generator designs. The integration of IoT technologies will enable remote monitoring, predictive maintenance, and enhanced performance optimization. Furthermore, there will be a growing emphasis on using renewable energy sources and developing more fuel-efficient and environmentally friendly generator technologies. The demand for single phase generators is expected to remain strong in the coming years, driven by factors such as increasing urbanization, growing demand for electricity in developing countries, and the need for backup power solutions in critical infrastructure. The factories that can adapt to these changing trends and embrace innovation will be the ones that thrive in the long run. Ultimately, the future hinges on efficiency, adaptability, and a commitment to meeting evolving energy needs.

In conclusion, the single phase generators factory is a complex and dynamic environment where raw materials are transformed into essential power solutions. From the initial design and engineering to the final testing and quality control, every stage of the production process is critical. Choosing the right factory requires careful consideration of factors such as reputation, product range, price, quality control, and customer service. As technology continues to advance and environmental concerns become more pressing, the single phase generators factory of the future will be characterized by increased automation, greater customization, and a stronger focus on sustainability. The factories that embrace innovation and adapt to changing customer needs will be the ones that succeed in the long run, continuing to provide reliable and efficient single-phase power to a world that increasingly relies on it.