Industrial power generators represent a cornerstone of modern infrastructure, providing essential power for a vast array of operations, from manufacturing plants and data centers to hospitals and construction sites. Understanding the nuances of these powerful machines is crucial for ensuring business continuity, safeguarding critical systems, and maintaining operational efficiency. Far from being a simple backup solution, industrial generators play diverse roles, ranging from providing prime power in remote locations to supplementing grid power during peak demand. The sheer scale and complexity of industrial power requirements necessitate careful consideration when selecting, installing, and maintaining these vital pieces of equipment. What factors do you consider most crucial when evaluating the power needs of your industrial facility?

The Core Functions of Industrial Power Generators

The primary function of an industrial power generator is to provide a reliable source of electricity, but the context of that reliability can vary greatly. Backup power is perhaps the most widely recognized application, where the generator automatically kicks in when the primary power source fails, preventing costly downtime and protecting sensitive equipment. Consider a large data center: a momentary power interruption can result in data loss, system crashes, and significant financial repercussions. A robust backup generator ensures seamless operation, minimizing disruption and maintaining data integrity. Beyond backup power, many industries rely on generators for prime power, especially in locations where grid access is limited or non-existent. Mining operations, construction sites in remote areas, and offshore oil platforms all frequently utilize generators as their primary power source. In these scenarios, generators must be capable of handling continuous, heavy loads for extended periods.

Another important, although less discussed function, is peak shaving. This involves using a generator to supplement the grid during periods of high demand, reducing the strain on the utility infrastructure and potentially lowering energy costs for the industrial facility. By strategically deploying generators during peak hours, businesses can avoid expensive demand charges levied by utility companies. Furthermore, some companies participate in demand response programs, where they agree to reduce their grid consumption during peak times in exchange for financial incentives. Generators play a key role in enabling participation in these programs. The flexibility and adaptability of industrial power generators make them indispensable assets for a wide range of industrial applications. Have you considered the potential cost savings of peak shaving strategies for your industrial facility?

Types of Industrial Power Generators

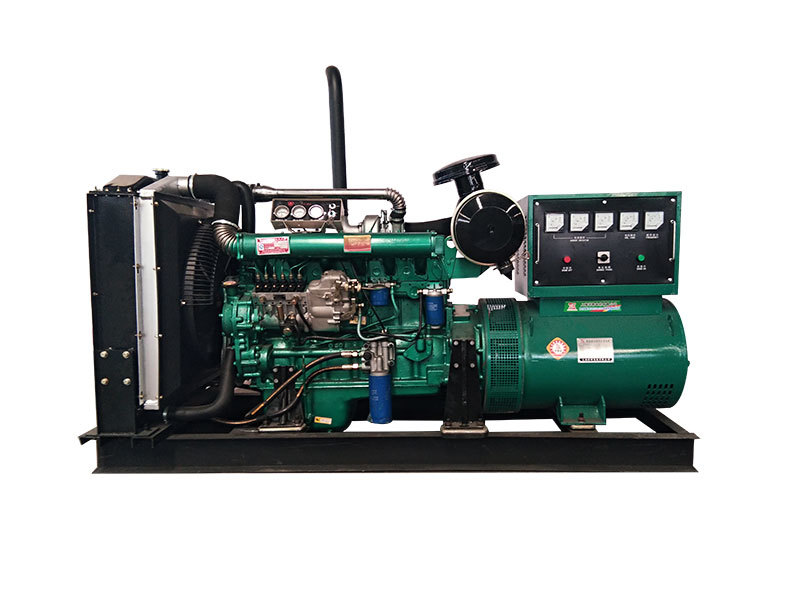

Industrial power generators come in various forms, each with its own set of advantages and disadvantages. Diesel generators are perhaps the most common type, known for their reliability, durability, and relatively low operating costs. Diesel fuel is readily available and provides a high energy density, making these generators a practical choice for many industrial applications. However, diesel generators can be noisy and emit pollutants, necessitating careful consideration of environmental regulations and noise mitigation strategies. Natural gas generators offer a cleaner-burning alternative, producing fewer emissions and operating more quietly than their diesel counterparts. Natural gas is often a more cost-effective fuel source as well, particularly in areas with access to natural gas pipelines. However, the availability of natural gas can be a limiting factor in some locations.

Beyond diesel and natural gas, propane generators provide a portable and versatile option, suitable for temporary power needs or applications where fuel storage space is limited. Propane is relatively clean-burning and readily available in many areas. Bi-fuel generators offer the flexibility to run on either diesel or natural gas, providing redundancy and allowing businesses to switch fuel sources based on cost and availability. Finally, renewable energy generators, such as solar and wind-powered systems, are gaining traction as a more sustainable alternative. While not always suitable as a primary power source due to their intermittent nature, renewable energy generators can be integrated with traditional generators to reduce reliance on fossil fuels and lower carbon emissions. The choice of generator type depends on a variety of factors, including power requirements, fuel availability, environmental considerations, and budget constraints.

Key Considerations When Selecting an Industrial Power Generator

Selecting the right industrial power generator requires a thorough assessment of power needs, site conditions, and operational requirements. Power output is a critical factor; the generator must be capable of handling the maximum load demand of the facility, with a safety margin to accommodate future growth and unexpected surges. Over-sizing a generator can lead to inefficiencies and higher operating costs, while under-sizing can result in inadequate power supply and potential damage to equipment. Fuel efficiency is another important consideration, especially for generators that will be operating for extended periods. Fuel costs can represent a significant portion of the total operating expenses, so choosing a generator with high fuel efficiency can result in substantial savings over the long term.

The generator's location plays a vital role in determining the appropriate noise level and emissions standards. Residential or noise-sensitive areas may require generators with sound attenuation features, while industrial areas may have stricter emissions regulations. Maintenance requirements should also be taken into account. Regular maintenance is essential for ensuring the reliability and longevity of the generator, so it's important to choose a model that is easy to service and maintain. Availability of spare parts and qualified service technicians are also crucial factors. Finally, cost is always a consideration, but it's important to look beyond the initial purchase price and consider the total cost of ownership, including fuel costs, maintenance expenses, and potential downtime costs. A seemingly cheaper generator may end up being more expensive in the long run if it's less reliable or fuel-efficient. Have you considered the life-cycle cost of your industrial generator options?

Installation and Maintenance Best Practices

Proper installation and regular maintenance are essential for ensuring the reliable and efficient operation of industrial power generators. Installation should be performed by qualified technicians, following manufacturer's guidelines and local building codes. The generator should be placed on a level, stable surface, with adequate ventilation and access for maintenance. Fuel lines and electrical connections should be properly sized and installed to prevent leaks and electrical hazards. A transfer switch is a critical component that automatically switches the power source from the grid to the generator in the event of a power outage. The transfer switch should be properly sized and installed to ensure a seamless transition and prevent backfeeding of power into the grid.

Maintenance should be performed on a regular schedule, following the manufacturer's recommendations. This typically includes checking fluid levels, changing filters, inspecting belts and hoses, and testing the generator under load. Proper lubrication is crucial for preventing wear and tear on moving parts. Regular testing helps to identify potential problems before they escalate into major failures. Keeping detailed maintenance records is essential for tracking performance and identifying trends. Early detection of potential problems can prevent costly repairs and downtime. Failure to adhere to proper maintenance schedules can invalidate warranties and shorten the lifespan of the generator. Are you maintaining detailed records of your generator maintenance activities?

Practical Applications of Industrial Power Generators

The applications of industrial power generators are incredibly diverse. Manufacturing plants rely on generators to maintain production during power outages, preventing costly downtime and ensuring the continuous operation of critical machinery. A sudden power loss can halt production lines, damage equipment, and result in significant financial losses. Hospitals depend on generators to power life-support systems, operating rooms, and other critical medical equipment, ensuring patient safety during emergencies. Generators are also essential for maintaining the temperature and humidity in pharmaceutical storage facilities, protecting sensitive medications from spoilage. Data centers require a constant and uninterrupted power supply to maintain server uptime and prevent data loss. Even brief power interruptions can cause system crashes and data corruption, resulting in significant financial and reputational damage.

Construction sites often rely on generators to power tools, lighting, and other equipment, especially in remote locations without access to the grid. Generators provide the power needed for welding, cutting, and other essential construction activities. Telecommunications companies use generators to maintain network connectivity during power outages, ensuring that customers can continue to make calls and access data. Wastewater treatment plants rely on generators to power pumps and other equipment, preventing sewage overflows and protecting public health. In the aftermath of natural disasters, industrial power generators can provide essential power for emergency services, shelters, and communication networks, aiding in rescue and recovery efforts. These are just a few examples of the many ways in which industrial power generators contribute to the smooth functioning of society and the economy.

The Future of Industrial Power Generation

The future of industrial power generation is likely to be shaped by several key trends. Increased efficiency is a major focus, as businesses seek to reduce fuel consumption and lower operating costs. Advancements in engine technology, such as improved combustion systems and variable speed generators, are helping to improve fuel efficiency. Alternative fuels, such as biodiesel and renewable natural gas, are gaining traction as a more sustainable alternative to traditional fossil fuels. These fuels can reduce greenhouse gas emissions and improve air quality. Smart generators are equipped with sensors and control systems that allow for remote monitoring, diagnostics, and optimization. These technologies can help to improve reliability, reduce maintenance costs, and enhance overall performance.

Microgrids, which are localized power grids that can operate independently from the main grid, are becoming increasingly popular for industrial facilities. Microgrids can integrate generators with renewable energy sources, such as solar and wind power, to create a more resilient and sustainable power supply. Battery storage is also playing a growing role in industrial power systems. Batteries can store excess energy generated by renewable sources or generators, providing backup power and reducing reliance on the grid. As the demand for reliable and sustainable power continues to grow, industrial power generators will continue to evolve and adapt to meet the changing needs of businesses and society. Understanding these trends is crucial for making informed decisions about power generation investments and ensuring long-term operational efficiency.

Ensuring Business Continuity with Industrial Power Generators

Ultimately, the value of industrial power generators lies in their ability to ensure business continuity. By providing a reliable source of backup or prime power, generators protect against costly downtime, safeguard critical systems, and maintain operational efficiency. The choice of generator type, size, and configuration depends on the specific needs of the industrial facility, but the underlying goal is always the same: to minimize disruption and maximize productivity. Investing in a high-quality generator and implementing a comprehensive maintenance program are essential for ensuring the long-term reliability and performance of the system. Regular testing, proper maintenance, and prompt repairs are crucial for preventing unexpected failures and maximizing the lifespan of the generator.

A well-maintained industrial power generator is a valuable asset that can provide peace of mind and protect against unforeseen events. In an increasingly interconnected and power-dependent world, the importance of reliable power generation cannot be overstated. From manufacturing plants to hospitals to data centers, industrial power generators play a vital role in keeping businesses running and society functioning smoothly. Choosing the right generator and implementing a robust maintenance program are critical steps in ensuring business continuity and protecting against the potentially devastating consequences of power outages. Therefore, careful consideration of your specific needs and a proactive approach to maintenance are crucial for maximizing the benefits of industrial power generators and safeguarding your operations.

`