The role of a custom generator manufacturer extends far beyond simply assembling pre-fabricated components. It’s about understanding the unique power requirements of a client, delving into the intricacies of their operation, and engineering a solution that fits like a glove. This process necessitates a blend of electrical, mechanical, and software engineering expertise, coupled with a keen understanding of regulatory compliance and environmental considerations. Think of it less as buying a product and more as investing in a partnership that ensures reliable power for your specific needs. The benefits of a custom solution are significant, including optimized efficiency, reduced operational costs, and a longer lifespan compared to off-the-shelf models. Choosing the right manufacturer, therefore, becomes a critical decision with long-term implications for operational success and cost savings.

Understanding the Scope of Customization

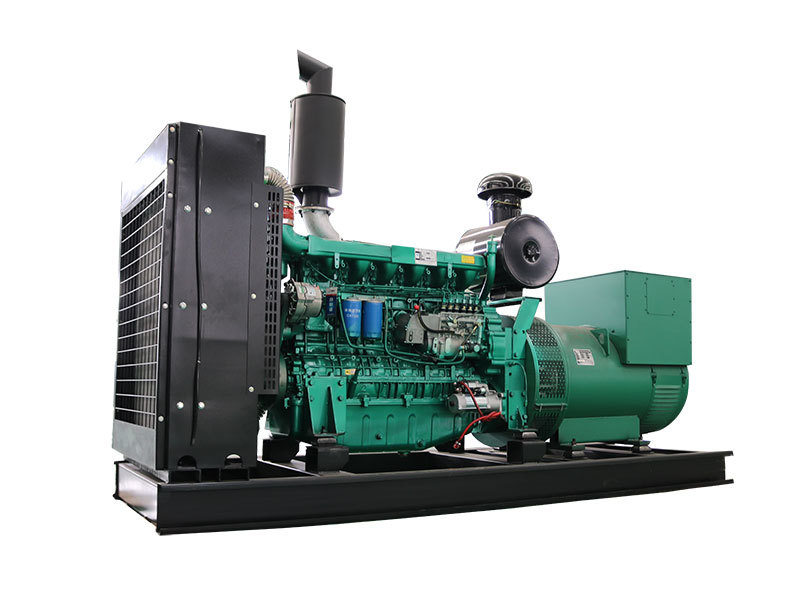

What exactly does it mean to have a generator customized? It encompasses a wide range of possibilities, from selecting the appropriate engine and alternator combination for optimal power output and fuel efficiency, to designing a bespoke control system tailored to specific load management needs. Customization can also involve adapting the generator's enclosure to suit harsh environmental conditions, integrating it seamlessly with existing infrastructure, and implementing specialized monitoring and diagnostic systems. Furthermore, a custom generator manufacturer might be tasked with developing unique safety features or integrating the generator into a larger microgrid or renewable energy system. Consider a remote mining operation in a desert environment – they would likely require a generator with a specialized cooling system, dust filters, and a robust enclosure designed to withstand extreme temperatures and abrasive particles. This is just one example highlighting the need for tailored power solutions in diverse industries.

The Benefits of Choosing a Custom Solution

The advantages of opting for a custom-built generator are numerous, beginning with optimized performance. A generator designed specifically for your application will operate more efficiently, reducing fuel consumption and minimizing emissions. This not only translates to significant cost savings over the lifespan of the generator but also contributes to a more sustainable operation. Moreover, a custom solution allows for greater control over system integration, ensuring seamless compatibility with existing infrastructure and avoiding costly retrofits. Another key benefit is enhanced reliability. By selecting components and configurations that are ideally suited to the operating environment, a custom generator manufacturer can minimize the risk of breakdowns and downtime. In critical applications, such as hospitals or data centers, where power outages can have catastrophic consequences, this reliability is paramount. Imagine the difference between a generic generator struggling to meet the demands of a specialized manufacturing process and a custom-designed unit that consistently delivers the precise power required with minimal interruption.

Key Considerations When Selecting a Manufacturer

Selecting the right custom generator manufacturer is a crucial decision that requires careful consideration. Begin by evaluating the manufacturer's experience and expertise in your specific industry. Do they have a proven track record of delivering successful projects in similar applications? Look for evidence of their engineering capabilities, including their ability to perform detailed load analysis, develop custom control systems, and integrate advanced monitoring technologies. It’s also vital to assess their manufacturing processes and quality control procedures. Are they certified to industry standards such as ISO 9001? Do they conduct rigorous testing of all components and finished products? Furthermore, consider their after-sales support capabilities. Do they offer comprehensive maintenance and repair services, as well as remote monitoring and diagnostic support? A reputable custom generator manufacturer will provide ongoing support throughout the lifespan of the generator, ensuring optimal performance and minimizing downtime. What specific certifications and industry affiliations should you prioritize when evaluating a prospective manufacturer?

The Engineering Process: From Concept to Completion

The engineering process undertaken by a reputable custom generator manufacturer is a detailed and collaborative endeavor. It typically begins with a thorough consultation to understand the client's specific power requirements, operating environment, and budgetary constraints. This is followed by a detailed load analysis to determine the optimal generator size and configuration. The engineering team then develops a custom design, incorporating the appropriate engine, alternator, control system, and enclosure. This design is typically presented to the client for review and approval before proceeding to the manufacturing phase. During manufacturing, the generator is assembled according to the approved design, using high-quality components and adhering to strict quality control procedures. Once assembled, the generator undergoes rigorous testing to ensure that it meets all performance specifications. Finally, the generator is delivered to the client's site, installed, and commissioned by experienced technicians. The entire process is carefully managed to ensure that the project is completed on time and within budget. What level of involvement do you expect from the manufacturer during the design and testing phases?

Materials, Components, and Technological Advancements

The selection of materials and components plays a crucial role in the performance and longevity of a custom generator. High-quality engines, alternators, and control systems are essential for reliable power generation. A reputable custom generator manufacturer will source components from trusted suppliers and rigorously test them to ensure that they meet stringent quality standards. The materials used for the generator's enclosure should also be carefully selected to withstand the specific environmental conditions in which the generator will be operating. For example, in coastal environments, corrosion-resistant materials are essential. Furthermore, advancements in technology are constantly driving innovation in the generator industry. This includes the development of more efficient engines, more advanced control systems, and more sophisticated monitoring and diagnostic tools. A forward-thinking custom generator manufacturer will embrace these advancements and incorporate them into their designs to provide clients with the most reliable and efficient power solutions available. For example, some manufacturers are now offering generators with remote monitoring capabilities that allow them to proactively identify and address potential issues before they lead to downtime. How important is it to you that your generator incorporates the latest technological advancements?

Integrating Custom Generators into Existing Systems

Successfully integrating a custom generator into an existing power system requires careful planning and execution. A key consideration is ensuring seamless compatibility with existing infrastructure, including electrical panels, switchgear, and transfer switches. A reputable custom generator manufacturer will work closely with the client's engineering team to develop a detailed integration plan that minimizes disruption and avoids costly retrofits. This plan should address issues such as voltage compatibility, frequency synchronization, and load sharing. Furthermore, it is essential to ensure that the generator is properly grounded and protected against electrical faults. The integration process may also involve configuring the generator's control system to communicate with existing monitoring and control systems. In some cases, it may be necessary to install additional equipment, such as surge suppressors or harmonic filters, to protect the generator and other sensitive equipment from electrical disturbances. Consider a hospital needing a backup generator – seamless transition during a power outage is critical, demanding meticulous integration with existing systems and backup power infrastructure.

Case Studies: Real-World Applications of Custom Generators

Examining real-world applications of custom generators can provide valuable insights into the benefits of tailored power solutions. Consider a data center that requires a highly reliable backup power system to protect its critical infrastructure. A custom generator manufacturer designed a solution that included redundant generators, automatic transfer switches, and a sophisticated monitoring system. This ensures that the data center can seamlessly switch to backup power in the event of a utility outage, minimizing downtime and preventing data loss. Another example is a construction site in a remote location that requires a portable generator to power heavy equipment. The manufacturer designed a generator with a rugged enclosure, a high-capacity fuel tank, and a user-friendly control panel. This allows the construction crew to work efficiently and safely in a challenging environment. These case studies highlight the diverse range of applications for custom generators and demonstrate the value of partnering with a manufacturer that can provide tailored solutions to meet specific needs. Think about the unique power needs of a film production company shooting on location – a customized generator, designed for quiet operation and portability, could be essential for their operations.

The Future of Custom Generator Manufacturing

The future of custom generator manufacturing is likely to be shaped by several key trends. One trend is the increasing demand for more sustainable power solutions. This is driving the development of generators that are powered by renewable fuels, such as biodiesel and biogas. Another trend is the growing importance of remote monitoring and diagnostic capabilities. This allows generator owners to proactively identify and address potential issues before they lead to downtime. Furthermore, advancements in technology are enabling the development of more compact and efficient generators. This is particularly important for applications where space is limited. As the demand for reliable and sustainable power solutions continues to grow, the role of the custom generator manufacturer will become increasingly important. These manufacturers will need to be able to provide innovative and tailored solutions that meet the evolving needs of their clients. In what ways do you foresee advancements in battery storage technology impacting the demand for custom generators in the future?

In conclusion, selecting a custom generator manufacturer is a significant investment that can yield substantial long-term benefits. By choosing a partner with the expertise, experience, and commitment to quality, you can ensure that you have a reliable and efficient power solution that meets your specific needs. The journey from initial consultation to final installation requires a collaborative approach, ensuring that the final product not only meets but exceeds expectations. Ultimately, a custom generator is not just a piece of equipment; it’s a strategic asset that can contribute to the success and sustainability of your operations.