The 40kW diesel engine, specifically the K4100ZD model, represents a significant workhorse in the world of power generation. It’s a prime example of how internal combustion technology continues to provide reliable energy across diverse applications. When we talk about a 40kW diesel engine, we're not just discussing a component; we're looking at the heart of a system designed to deliver consistent electrical power, particularly when paired with a generator. Understanding the capabilities and applications of this engine, especially within machinery settings, is crucial for anyone involved in power solutions, from engineers to facility managers. The K4100ZD further specifies this engine, providing a more focused understanding of its particular characteristics and design elements that contribute to its overall performance. Let's delve into the various aspects that make this combination a staple in the industry.

Understanding the K4100ZD Diesel Engine

The K4100ZD diesel engine isn't just any generic engine; it's engineered for durability and reliability, two paramount considerations for engines powering generators. Its design typically incorporates robust components built to withstand continuous operation, reducing the likelihood of breakdowns and minimizing downtime. One key element of the K4100ZD's design is its fuel efficiency. Diesel engines, in general, are known for their higher thermal efficiency compared to gasoline engines. The K4100ZD is designed to extract the maximum amount of energy from each drop of fuel, contributing to lower operating costs over its lifespan. This is often achieved through precise fuel injection systems and optimized combustion chamber designs. Furthermore, the engine's construction often emphasizes accessibility for maintenance. Regular servicing is crucial for extending the life of any engine, and the K4100ZD usually features easily accessible service points, simplifying tasks such as oil changes, filter replacements, and valve adjustments. This makes maintaining the engine easier. What design choices do you think are the most impactful when considering long-term performance and maintenance?

40kW Power Output: Matching Engine to Generator Needs

The 40kW power output of this engine is a critical factor in determining its suitability for various generator applications. This rating signifies the engine's capacity to continuously deliver 40 kilowatts of mechanical power, which is then converted into electrical power by the generator. Matching the engine's power output to the generator's capacity is crucial for optimal performance and efficiency. If the engine is undersized, it may struggle to meet the generator's demand, leading to voltage drops and potential damage. Conversely, an oversized engine may operate inefficiently, consuming more fuel than necessary. Therefore, careful consideration is given to the power requirements of the intended load and the generator's efficiency when selecting a 40kW diesel engine. The 40kW rating makes the K4100ZD a suitable choice for applications ranging from powering small industrial equipment and construction sites to serving as backup power for essential systems in commercial buildings or even providing electricity to remote communities.

Diesel Engine Advantages in Generator Applications

Diesel engines possess several advantages that make them well-suited for generator applications. These engines are renowned for their ruggedness and long service life, enabling them to withstand prolonged periods of continuous operation, which is often required for backup power systems or in remote locations. The reliability stems from their inherent design characteristics, such as their higher compression ratios and robust construction, enabling them to withstand harsher operating conditions. Furthermore, diesel engines typically offer better fuel efficiency compared to gasoline engines, reducing operational costs over their lifespan. The availability of diesel fuel is another advantage, as it is widely available in most regions, facilitating easy refueling in diverse settings. In addition to that, many modern diesel engines are equipped with electronic control systems that optimize performance, enhance fuel efficiency, and provide diagnostic capabilities for troubleshooting. These systems contribute to improved overall performance and reduced maintenance requirements.

K4100ZD in Machinery Applications Beyond Generators

While the 40kW K4100ZD diesel engine is widely used for generators, its versatility extends beyond power generation. Its robust design and reliable performance make it suitable for various machinery applications. Construction equipment, such as small excavators, loaders, and concrete mixers, often utilize diesel engines in this power range. Agricultural machinery, including tractors, irrigation pumps, and harvesters, can also benefit from the engine's torque and efficiency. Industrial equipment, such as air compressors, welding machines, and hydraulic power packs, are other potential applications. The K4100ZD’s adaptability stems from its ability to provide consistent power and torque under varying load conditions. In these machinery applications, the engine often needs to operate for extended periods under heavy workloads, and the K4100ZD is designed to meet these demands. Often these non-generator applications also prioritize long lifespan and relatively easy maintenance, fitting well with the engine's design goals.

Maintenance and Longevity of the K4100ZD Engine

Proper maintenance is crucial for maximizing the lifespan and performance of any diesel engine, including the K4100ZD. Regular servicing, as per the manufacturer's recommendations, is essential for preventing premature wear and tear and ensuring optimal operation. This includes routine tasks such as oil changes, filter replacements (air, fuel, and oil), coolant checks, and inspection of belts and hoses. Following a preventative maintenance schedule can identify potential problems early on, preventing costly repairs and downtime. Additionally, it is crucial to use high-quality lubricants and filters that meet the engine's specifications. These components play a vital role in protecting the engine from wear and tear. Proper storage and handling of fuel are also essential to prevent contamination and ensure smooth operation. Over time, components like injectors and pumps can degrade, so scheduling regular checks and possible replacements can help keep everything running smoothly. Considering these factors helps extend the K4100ZD's operational life.

Integrating the K4100ZD with Generators: A Technical Overview

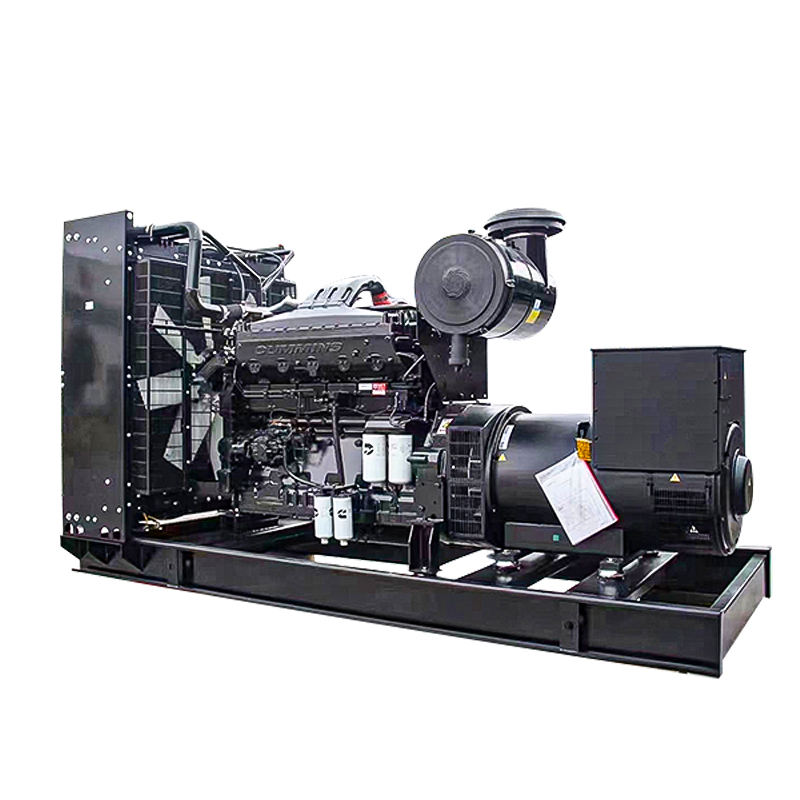

The integration of the K4100ZD diesel engine with a generator involves carefully matching the engine's mechanical output with the generator's electrical output characteristics. This requires precise alignment, coupling, and control systems. The engine's crankshaft is typically coupled directly to the generator's rotor, transmitting the mechanical power produced by the engine to the generator. A control panel is used to monitor and control the engine's operation, including starting, stopping, and adjusting speed and load. The control panel also provides protection against overloads, over-speed, and other abnormal conditions. Furthermore, the engine and generator are often mounted on a common base frame to provide stability and minimize vibration. Proper ventilation is crucial for dissipating heat generated by both the engine and the generator. In many applications, sound attenuation measures are also implemented to reduce noise levels. The cooling system is a critical aspect of the integration, designed to maintain optimal engine temperature and prevent overheating. These technical aspects are important for proper operation.

Real-World Applications of K4100ZD Powered Generators

The applications of generators powered by the 40kW K4100ZD diesel engine are wide-ranging and impactful. They provide essential backup power for hospitals, ensuring continuous operation of life-support systems and critical medical equipment during power outages. Data centers rely on these generators to maintain uninterrupted power supply to servers and networking equipment, preventing data loss and service disruptions. Construction sites utilize these generators to power tools, lighting, and other equipment, enabling work to continue even in the absence of grid electricity. Agricultural operations often depend on these generators to power irrigation systems, pumps, and other equipment, supporting crop production and livestock management. Remote communities, where grid electricity is unavailable or unreliable, utilize these generators as their primary source of power for homes, businesses, and essential services. The reliability and versatility of these generators make them essential components in various critical applications.

The Future of Diesel Engines in Power Generation

While the energy landscape is rapidly evolving with the rise of renewable energy sources, diesel engines continue to play a significant role in power generation, particularly in situations where reliability and portability are paramount. Advancements in diesel engine technology are focusing on improving fuel efficiency, reducing emissions, and integrating with alternative fuels. Technologies such as common-rail fuel injection, turbocharging, and exhaust gas recirculation (EGR) are being implemented to optimize combustion and minimize pollutants. The development of hybrid systems that combine diesel engines with battery storage or renewable energy sources is also gaining traction. These hybrid systems offer the potential to reduce fuel consumption, lower emissions, and improve overall system efficiency. Furthermore, research is underway to explore the use of biofuels and synthetic fuels in diesel engines, reducing reliance on fossil fuels. Diesel engines remain a viable and adaptable solution for diverse power generation needs, especially where dependability is paramount. What emerging technologies do you think will most impact the future of diesel engine applications?

Conclusion: The Enduring Relevance of the 40kW Diesel Engine K4100ZD

The 40kW diesel engine K4100ZD, as a prime mover for generators, remains a vital component in numerous applications, providing dependable power where it's needed most. Its robust design, fuel efficiency, and versatility make it a reliable choice for backup power systems, machinery operation, and remote power generation. While the energy landscape is changing, the K4100ZD's ability to deliver consistent and reliable power ensures its continued relevance in the foreseeable future. Its adaptability and improvements will allow it to play a major role. Its enduring presence underscores the importance of internal combustion engines in powering our world, especially in situations requiring consistent and readily available energy.