Generator sets, while indispensable for providing power in various situations, can be a significant source of noise pollution. This noise, often characterized by a low-frequency hum and potentially disruptive high-frequency components, isn't just a nuisance; it's often regulated by local, state, and federal authorities. Understanding and complying with these noise regulations for generator sets is crucial for avoiding fines, maintaining good community relations, and operating your equipment legally. This article dives deep into the complexities of noise regulations and offers practical, actionable solutions to help you achieve compliance and minimize noise impact.

Understanding the Landscape of Noise Regulations

Navigating the legal framework surrounding generator noise can feel like wading through a swamp. Different jurisdictions have different standards, and these standards can vary based on factors like zoning (residential vs. industrial), time of day (daytime vs. nighttime), and proximity to sensitive areas (hospitals, schools). Generally, noise regulations are expressed in decibels (dB), a logarithmic unit measuring sound pressure level. A key concept is the "A-weighted" decibel (dBA), which adjusts the measurement to reflect how the human ear perceives sound. Many regulations specify maximum permissible dBA levels at the property line or at a certain distance from the generator set. Failure to comply can result in warnings, fines, or even operational shutdowns. So, the first step is always to check your local ordinances and any applicable state or federal guidelines. Are you unsure where to start? Contacting your local environmental protection agency or a qualified noise consultant can provide clarity and ensure you're on the right track.

The Impact of Noise: More Than Just an Annoyance

While noise might seem like a minor inconvenience, its impact extends far beyond simple irritation. Prolonged exposure to high noise levels can lead to a variety of health problems, including hearing loss, sleep disturbances, increased stress, and even cardiovascular issues. Consider the impact on residential areas; a noisy generator operating late at night can disrupt sleep patterns and significantly reduce the quality of life for nearby residents. In industrial settings, excessive noise can impair communication, reduce productivity, and increase the risk of accidents. Beyond the human impact, noise pollution can also affect wildlife, disrupting natural habitats and breeding patterns. Therefore, addressing generator noise is not just about legal compliance; it's about promoting public health, environmental responsibility, and good corporate citizenship. Choosing a generator set with inherent sound dampening features can make a considerable difference, often reducing the need for extensive modifications later on.

Strategies for Achieving Noise Compliance: A Multi-Pronged Approach

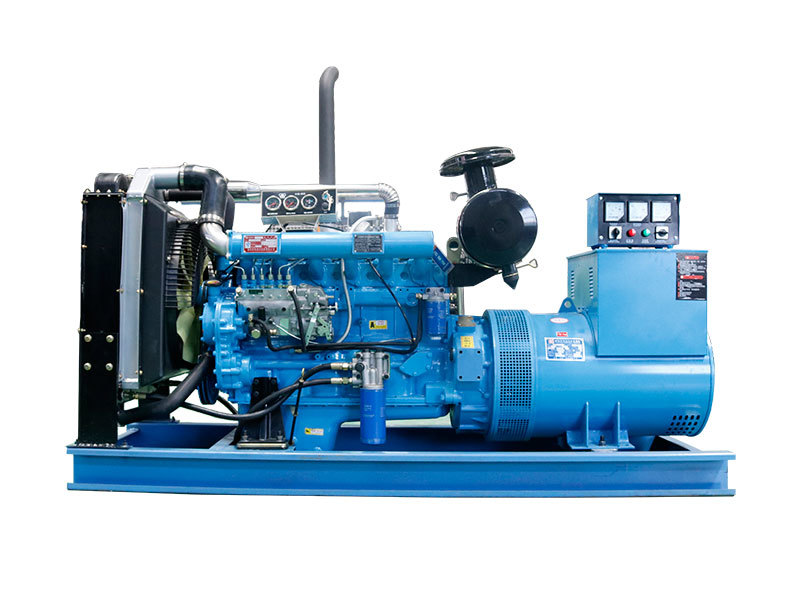

Achieving noise compliance often requires a multi-faceted approach that combines preventative measures with reactive solutions. This begins with selecting a generator set that inherently produces less noise. Look for models specifically designed for quiet operation, often featuring features like sound-attenuated enclosures and vibration dampening mounts. Next, consider the placement of the generator set. Locating it as far away as possible from noise-sensitive areas is a simple but effective strategy. Orienting the generator so that the exhaust and engine noise are directed away from neighbors can also make a noticeable difference. Finally, implementing noise mitigation measures, such as sound barriers, acoustic enclosures, and exhaust silencers, can further reduce noise levels. Remember that even small adjustments can have a significant impact, particularly when combined strategically. Do you find yourself struggling with fluctuating noise levels depending on generator load? Consider installing a variable exhaust silencer that adjusts its performance based on engine RPM.

Sound Barriers: Creating a Buffer Zone

Sound barriers are physical structures designed to block or deflect sound waves, creating a "shadow zone" of reduced noise levels. These barriers can be constructed from a variety of materials, including concrete, brick, wood, and specialized acoustic panels. The effectiveness of a sound barrier depends on its height, length, and material composition. A taller and longer barrier will generally provide greater noise reduction. The material should be dense and non-reflective to absorb sound rather than reflect it. Sound barriers can be particularly effective in situations where the generator set is located near a property line or residential area. Interestingly, a strategically placed barrier doesn't need to completely enclose the generator to be effective; even a partial barrier can significantly reduce noise levels in specific directions. When designing a sound barrier, consider the frequency of the noise being emitted by the generator set. Low-frequency sounds are more difficult to block than high-frequency sounds, requiring thicker and more robust materials.

Acoustic Enclosures: Containing the Noise Source

Acoustic enclosures offer a more comprehensive noise reduction solution by completely enclosing the generator set within a soundproof structure. These enclosures are typically constructed from metal or composite materials and lined with sound-absorbing materials, such as fiberglass or mineral wool. Acoustic enclosures can achieve significant noise reduction, often reducing noise levels by 15-30 dBA or more. They also offer the added benefit of protecting the generator set from the elements, extending its lifespan and reducing maintenance requirements. However, acoustic enclosures can be more expensive than other noise mitigation measures and may require professional installation. Proper ventilation is crucial to prevent overheating, so enclosures need to be designed with carefully calculated air intake and exhaust systems. In some cases, custom-designed enclosures are necessary to accommodate specific generator set models or site requirements.

Exhaust Silencers: Muffling the Roar

The exhaust system is often a major source of generator noise. Exhaust silencers, also known as mufflers, are designed to reduce the noise emitted from the exhaust by damping sound waves as they travel through the system. Silencers come in a variety of designs, each offering different levels of noise reduction. Reactive silencers use internal baffles to reflect and cancel out sound waves, while absorptive silencers use sound-absorbing materials to dampen the noise. The choice of silencer depends on the specific noise reduction requirements and the characteristics of the generator set. In some cases, multiple silencers may be used in series to achieve maximum noise reduction. It's important to choose a silencer that is compatible with the generator set's exhaust system and to ensure that it is properly installed to avoid leaks and performance issues. Using a high-quality exhaust silencer is a crucial step in achieving generator set soundproofing.

Long-Term Maintenance and Monitoring for Sustained Compliance

Even after implementing noise mitigation measures, it's essential to maintain a long-term monitoring and maintenance program to ensure continued compliance with noise regulations. This includes regularly inspecting sound barriers, acoustic enclosures, and exhaust silencers for damage or wear and tear. Any necessary repairs should be made promptly to prevent noise levels from increasing. Consider using sound level meters to periodically measure noise levels at various locations around the generator set. This will help you identify any potential issues early on and take corrective action before they escalate. Furthermore, it's crucial to stay informed about any changes to local, state, or federal noise regulations. Regulations can be updated periodically, and it's your responsibility to ensure that your generator set continues to comply with the latest requirements. Keeping a detailed record of noise measurements and maintenance activities can also be helpful in demonstrating compliance to regulatory authorities.

Leveraging Technology for Noise Control

Modern technology offers several advanced solutions for managing and mitigating generator noise. Active noise control (ANC) systems, for instance, use microphones and speakers to generate "anti-noise" waves that cancel out the original sound waves. While ANC systems are more complex and expensive than traditional noise mitigation measures, they can be highly effective in reducing low-frequency noise. Noise monitoring systems use sensors and data analytics to continuously track noise levels and provide real-time alerts when thresholds are exceeded. This allows for proactive intervention to prevent noise violations. Furthermore, advancements in generator set design have led to the development of quieter models that incorporate noise-reducing technologies at the source. Investing in these technologies can not only improve noise compliance but also enhance the overall performance and efficiency of your generator set.

Finding the Right Expertise: Consulting with Professionals

Navigating the complexities of noise regulations for generator sets and implementing effective noise mitigation strategies can be challenging. In many cases, it's beneficial to consult with qualified professionals who specialize in acoustics and noise control. These experts can conduct noise assessments, recommend appropriate mitigation measures, and ensure compliance with all applicable regulations. They can also provide guidance on selecting the right generator set for your specific needs, taking into account factors like noise levels, power requirements, and budget. Working with a professional can save you time, money, and headaches in the long run by ensuring that you're implementing the most effective and cost-efficient solutions. Remember, investing in professional expertise is an investment in compliance, peace of mind, and good community relations.

In conclusion, complying with noise regulations for generator sets requires a comprehensive understanding of the legal framework, a proactive approach to noise mitigation, and a commitment to long-term monitoring and maintenance. By implementing the strategies outlined in this article, you can minimize noise pollution, maintain compliance, and ensure a harmonious relationship with your neighbors. What specific noise challenges are you currently facing with your generator set, and what steps are you considering to address them? Taking action now can prevent future problems and contribute to a quieter, healthier environment. To start, explore the option of a noise assessment to accurately measure your generator's sound output and identify areas for improvement. Contact a certified acoustical consultant today for personalized guidance and solutions.