Introduction

When it comes to generator sets, cooling is a critical aspect that ensures optimal performance and longevity. In my experience, many people overlook the importance of choosing the right cooling technology. This article delves into the two primary cooling solutions: air and liquid cooling. By understanding their unique advantages and disadvantages, you can make an informed decision for your generator set's cooling needs.

How Do Generator Sets Generate Heat?

To appreciate the role of cooling technologies, let's first understand why generator sets produce heat. As it turns out, heat is a byproduct of the electrical energy generation process. The engine within the generator set burns fuel to generate mechanical energy, which is then converted into electrical energy. This energy conversion process releases heat, which must be dissipated to maintain optimal operating temperatures.

Air Cooling Solutions

Benefits of Air Cooling

Air cooling is a popular choice for smaller generator sets due to its simplicity and cost-effectiveness. Interestingly enough, air cooling systems rely on natural or forced air circulation to dissipate heat. Here are some benefits of air cooling solutions:

Drawbacks of Air Cooling

While air cooling offers numerous advantages, it's not without its limitations. Here are some drawbacks to consider:

- Size and noise restrictions: Air-cooled generator sets tend to be larger and noisier than liquid-cooled units, which may be a concern in residential or noise-sensitive applications.

- Limited cooling capacity: Air cooling may struggle to dissipate heat efficiently in high-ambient temperature environments or large power output applications.

Liquid Cooling Solutions

Benefits of Liquid Cooling

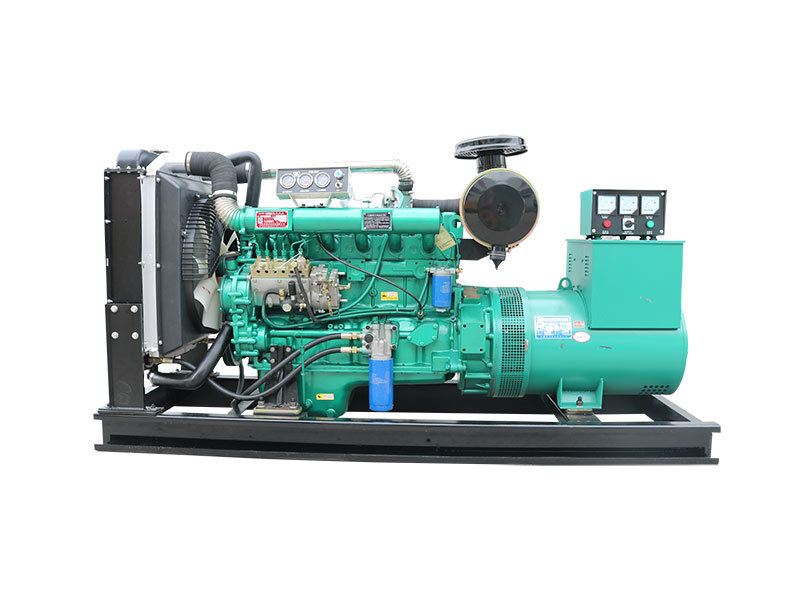

Liquid cooling is often the preferred choice for larger and more powerful generator sets. Liquid cooling systems use a combination of water, antifreeze, and coolant to absorb and dissipate heat. Here are some advantages of liquid cooling solutions:

- Compact and quiet: Liquid-cooled generator sets are typically smaller and quieter than air-cooled units, making them suitable for various applications.

- Enhanced cooling capacity: Liquid cooling provides superior heat dissipation, making it ideal for high-power output applications or environments with extreme ambient temperatures.

- Longer lifespan: Due to more consistent operating temperatures, liquid-cooled generator sets often have longer service lives than air-cooled units.

Drawbacks of Liquid Cooling

Despite its advantages, liquid cooling does have some potential downsides:

- Higher initial costs: Liquid-cooled generator sets tend to be more expensive than air-cooled units due to their complexity.

- Increased maintenance: Liquid cooling systems have more moving parts and require more frequent maintenance, such as coolant changes.

Making the Right Choice

When deciding between air and liquid cooling solutions for your generator set, consider factors such as the required power output, ambient temperatures, noise restrictions, and budget. In many cases, air cooling may be sufficient for smaller, lower-power applications, while liquid cooling is better suited for larger, more powerful generator sets or extreme environments.

Conclusion

In conclusion, understanding the differences between air and liquid cooling technologies is crucial for selecting the right generator set cooling solution. Each technology has unique advantages and disadvantages that should be carefully considered based on your specific needs. By making an informed decision, you can ensure optimal performance, efficiency, and longevity for your generator set.

So, what's your next step? If you're still unsure about which cooling technology is best for your generator set, consult with a trusted industry professional or manufacturer. They can provide personalized recommendations based on your unique requirements and help you make the most informed decision possible.