The Importance of Precision and Excellence in Generator Set Production

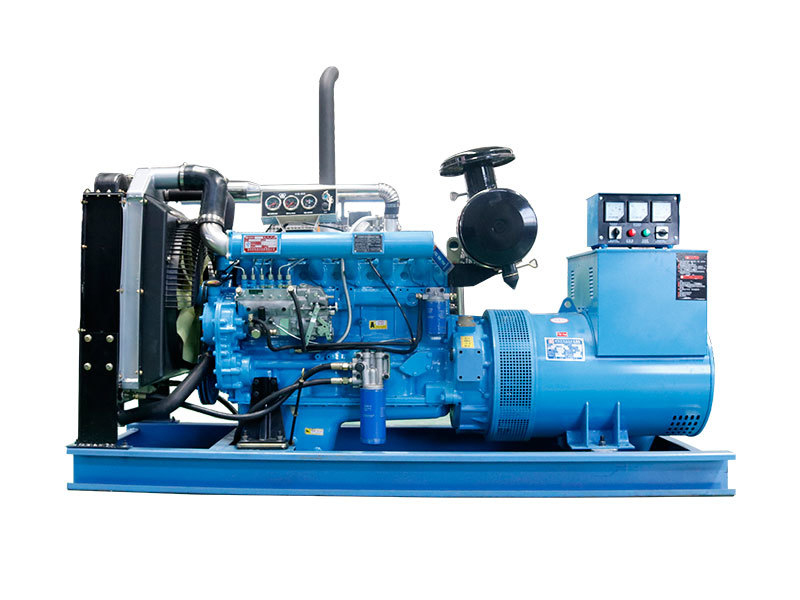

When it comes to manufacturing generator sets, precision and excellence are absolutely necessary. Generator sets are responsible for providing power during emergencies, outages, and in remote locations, so it's crucial that they operate reliably and efficiently. To achieve this level of performance, manufacturers must adhere to strict production processes that prioritize precision and excellence.

Design and Engineering

The first step in generator set production is design and engineering. This is where manufacturers determine the specifications of the generator set, including its size, power output, and fuel type. They must also consider factors such as noise levels and emissions. To ensure that the generator set meets these specifications, manufacturers use computer-aided design (CAD) software to create detailed drawings and models of the machinery.

Manufacturing and Assembly

Once the design and engineering phase is complete, the manufacturing process begins. This involves machining, welding, and assembling the various components of the generator set. To ensure precision and accuracy, manufacturers use computer numerical control (CNC) machines to produce parts with tight tolerances. They also employ skilled workers to assemble the components, ensuring that everything fits together perfectly.

Quality Control and Testing

Quality control is an essential aspect of generator set production. Manufacturers must ensure that every generator set meets their high standards for performance and reliability. To do this, they conduct rigorous testing and inspection throughout the production process. This includes testing for electrical and mechanical performance, as well as testing for safety and environmental compliance.

Electrical Performance Testing

Electrical performance testing is critical for ensuring that the generator set will provide reliable power when it's needed. This involves testing the generator's ability to produce and maintain a consistent voltage and frequency output. Manufacturers also test the generator's ability to handle various loads, ensuring that it can provide power to a range of equipment and appliances.

Mechanical Performance Testing

Mechanical performance testing is equally important. This involves testing the generator's engine, alternator, and other components to ensure that they are operating efficiently and reliably. Manufacturers also test the generator's cooling and exhaust systems to ensure that they are functioning properly.

Safety and Environmental Compliance Testing

Safety and environmental compliance testing is essential for ensuring that the generator set meets regulatory standards and poses no risk to users or the environment. This includes testing for electrical safety, as well as testing for emissions and noise levels. Manufacturers must also ensure that the generator set is designed and built to withstand various environmental conditions, including extreme temperatures, humidity, and dust.

Service and Support

Once the generator set is manufactured, it's important that it's properly maintained to ensure optimal performance and longevity. Manufacturers provide service and support to their customers, including regular maintenance and repair services. They also offer training and resources to help users operate and maintain the generator set safely and effectively.

Maintenance and Repair Services

Regular maintenance is essential for keeping the generator set in good working order. Manufacturers offer maintenance services that include inspecting and servicing the generator set's engine, alternator, and other components. They also offer repair services for any issues that may arise, ensuring that the generator set is quickly restored to full functionality.

Training and Resources

Manufacturers also provide training and resources to help users operate and maintain the generator set safely and effectively. This includes user manuals, training videos, and other educational materials. They also offer on-site training and support for more complex installations and applications.

Conclusion

The production of generator sets is a complex process that requires precision and excellence at every stage. From design and engineering to manufacturing and assembly, quality control and testing, and service and support, manufacturers must prioritize performance, reliability, and safety. By doing so, they can provide their customers with generator sets that deliver reliable power when it's needed most.