In today's world, where continuity of operations is paramount, having a dependable power source is non-negotiable for many businesses and institutions. Grid power is generally reliable, yes, but unpredictable outages can occur due to weather events, grid overload, or unexpected equipment failures. For operations that simply cannot afford downtime – think hospitals, data centers, manufacturing facilities, or even large retail complexes – a robust backup power solution isn't a luxury; it's an absolute necessity. This is where the power generator steps in, providing that critical bridge during grid interruptions. While diesel has traditionally been the go-to fuel, natural gas generators have surged in popularity, offering distinct advantages that align with modern demands for efficiency, environmental considerations, and convenience. Specifically, the natural gas generator 200kw size class represents a sweet spot for a wide range of medium to large-scale applications, providing substantial power output capable of keeping significant operations running smoothly when the mains fail. Understanding the capabilities and benefits of this particular size unit is crucial for anyone evaluating their backup or prime power needs.

The Fuel Advantage: Why Natural Gas for Generators?

Comparing natural gas to other fuel sources for power generation reveals several compelling reasons for its increasing adoption, particularly for units like a natural gas generator 200kw. Firstly, and often most importantly, natural gas is typically delivered via pipeline, which means you don't need to store large quantities of fuel on-site in tanks. This eliminates the space requirement for fuel storage, reduces security concerns associated with stored fuel, and removes the logistical headache of refueling, especially during an extended outage when fuel deliveries might be difficult or impossible. To be honest, the convenience of a continuous fuel supply directly from the utility line is a major operational advantage. Secondly, natural gas combustion is inherently cleaner than diesel. This translates to lower emissions of particulate matter, nitrogen oxides (NOx), and sulfur oxides (SOx), making natural gas generators a more environmentally friendly option that can often meet stricter air quality regulations without requiring complex and costly exhaust after-treatment systems. Frankly speaking, this clean burning characteristic is a significant factor for businesses operating in urban areas or those with corporate sustainability goals. Lastly, while fuel costs fluctuate, natural gas has often been more stable and potentially lower in cost compared to diesel fuel over the long term, contributing to lower operational expenses for the generator.

Environmental Benefits of Natural Gas Combustion

Delving deeper into the environmental profile, the combustion of natural gas produces significantly less greenhouse gas emissions compared to diesel, gasoline, or coal, particularly regarding CO2 per unit of energy produced. While it is still a fossil fuel, its cleaner burning nature means less soot, fewer harmful pollutants being released into the atmosphere, and generally lower noise levels during operation compared to many diesel counterparts, though this can vary depending on the generator's enclosure and design. For businesses prioritizing their environmental footprint or facing stringent local emission standards, choosing a natural gas generator 200kw can be a key part of their strategy. Many experts agree that transitioning to natural gas for stationary power generation offers a tangible step towards reducing localized air pollution and contributing to broader climate goals, even as we transition to renewable energy sources. It's worth noting that compliance with environmental regulations, such as those set by the EPA, is often simpler and less expensive with natural gas units due to their lower inherent emissions. This ease of compliance can save businesses considerable time and resources in the long run, allowing them to focus on their core operations rather than navigating complex regulatory hurdles.

Understanding the 200kW Capacity: Is it Right for You?

The choice of generator size is critical; too small and it won't power essential equipment, too large and you've invested unnecessarily while potentially operating inefficiently. The 200kW capacity is not arbitrary; it represents a power output capable of supporting substantial electrical loads. To put it in perspective, 200 kilowatts is equivalent to 200,000 watts or roughly 250 kVA (kilovolt-amperes), depending on the power factor. This capacity is well-suited for medium-sized facilities that require backup power for critical systems like HVAC, lighting, security systems, essential IT infrastructure, and manufacturing processes during an outage. It's often the chosen size for scenarios requiring more power than smaller commercial units (like 50-100kW) can provide, but where the massive scale of multi-megawatt industrial generators isn't necessary. Identifying whether a natural gas generator 200kw is the right fit involves a detailed load assessment. This means calculating the total power consumption of all equipment that absolutely must run during an outage, factoring in starting loads (the surge of power required when motors and other inductive loads first turn on), and adding a buffer for future expansion or safety. I've found that many businesses underestimate their starting loads, leading to undersized generators that fail to perform when needed. A professional load calculation is indispensable here to ensure you select a generator that is neither undersized nor excessively large for your specific operational needs and budget.

Matching Capacity to Specific Loads

Properly matching the 200kW capacity to your facility's load profile involves understanding both continuous running loads and intermittent surge loads. Continuous loads are the steady power requirements of equipment that will operate constantly, such as lighting systems, computers, servers, and basic HVAC. Surge loads, on the other hand, are temporary but significantly higher power demands, typically from electric motors when they start up (e.g., pumps, compressors, some manufacturing machinery). A generator must be capable of handling both the total continuous load and the peak surge load without stalling or tripping. For a 200kW unit, this capacity allows it to support a considerable amount of continuous load while still having enough headroom to accommodate the startup demands of multiple motors sequentially or simultaneously. Interestingly enough, the specific type of equipment being powered also influences the required generator specifications beyond just kW rating, such as voltage regulation, frequency stability, and transient response. For sensitive electronics, ensuring the generator provides stable, clean power is crucial. This is why simply matching the nameplate kW rating isn't enough; a thorough analysis of the specific loads and their characteristics is essential when considering a natural gas generator 200kw to guarantee reliable performance under real-world conditions during an emergency.

Common Applications for a 200kW Natural Gas Generator

The versatility and robust power output of a natural gas generator 200kw make it suitable for a diverse range of applications across various sectors. Many medium-sized commercial buildings, such as office complexes, retail centers, and larger restaurants, utilize this size for standby power to maintain essential services like lighting, elevators, point-of-sale systems, and HVAC during grid failures, ensuring customer comfort and business continuity. Healthcare facilities, including clinics, nursing homes, and smaller hospitals, rely on 200kW units to power critical systems like emergency lighting, medical equipment, and essential life support, where even a brief power interruption can have serious consequences. Light industrial facilities and manufacturing plants often deploy generators of this capacity to keep critical production lines operational or to safely shut down sensitive processes during outages, minimizing material waste and equipment damage. Data centers and IT facilities that aren't large enough to require multi-megawatt systems often find a 200kW generator perfect for powering essential servers, network equipment, and cooling systems to prevent data loss and maintain connectivity. Have you ever wondered how pharmacies keep temperature-sensitive medicines stable or how grocery stores prevent massive spoilage during an extended outage? A 200kW generator is frequently the answer, providing sufficient power for refrigeration units and essential lighting.

Commercial and Industrial Use Cases

Beyond the examples above, the application spectrum continues to broaden. Agricultural operations might use a 200kW unit to power pumps for irrigation or ventilation systems in barns and greenhouses. Educational institutions and research facilities need reliable power for laboratories, servers, and safety systems. Municipal buildings like fire stations, police stations, and community centers often require this level of power to serve as emergency shelters or maintain essential public services. Even large residential complexes or multi-unit buildings can benefit from a 200kW natural gas generator to ensure continued operation of common areas, security systems, elevators, and potentially critical services for residents. The key across all these applications is the need for significant, reliable backup power from a convenient fuel source. The ability of natural gas to be continuously supplied via pipeline is a distinct advantage in these settings, particularly for applications where outages could be prolonged, or where on-site fuel storage poses logistical or safety challenges. This makes the 200kW natural gas unit a highly practical and dependable choice for ensuring operational resilience in a wide array of commercial, institutional, and industrial environments, safeguarding against the unpredictable nature of grid power.

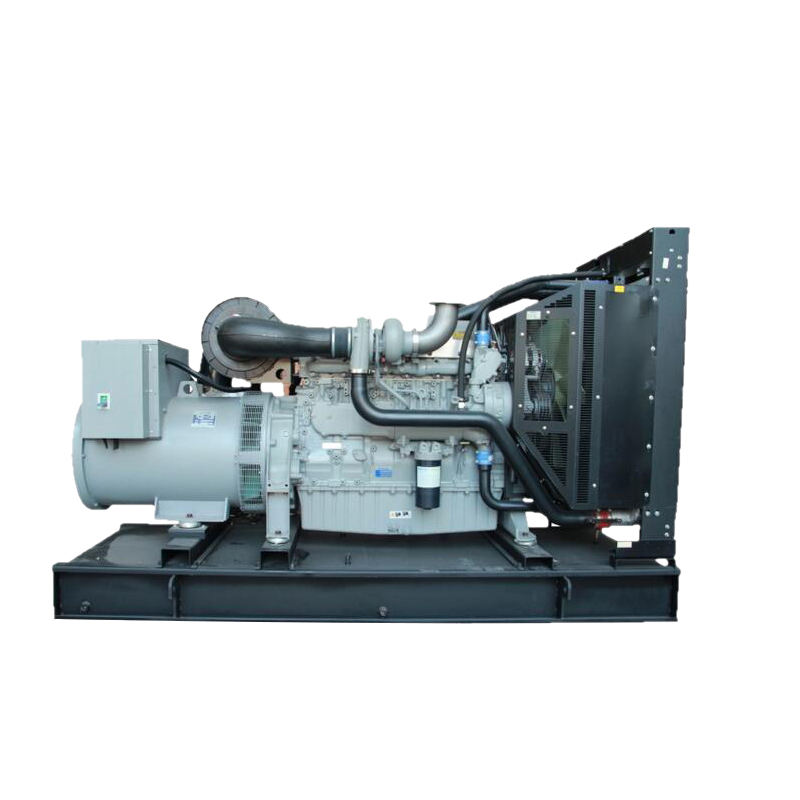

Essential Features to Look for in a 200kW Unit

Selecting a natural gas generator 200kw involves looking beyond just the power rating. Several key features contribute significantly to the generator's reliability, efficiency, ease of use, and overall lifespan. The engine is the heart of the generator, and for a unit of this size, you'll typically find robust industrial-grade engines designed for continuous or extended operation. Look for engines from reputable manufacturers known for durability and performance on natural gas fuel. The alternator, which converts mechanical energy from the engine into electrical energy, is equally important. Ensure it's properly matched to the engine and designed to handle the expected load types (including motor starting). The control system is the generator's brain. Modern controllers offer sophisticated monitoring, diagnostics, and remote management capabilities. A good control system allows you to track performance, fuel consumption, maintenance alerts, and even remotely start or stop the generator, providing invaluable insights and control. Enclosures are crucial for protecting the generator from weather and reducing noise. For many applications, especially in populated areas, a sound-attenuated enclosure is essential to meet local noise ordinances and minimize disturbance. Transfer switches are another critical component, seamlessly switching power from the utility grid to the generator when an outage occurs and back again when utility power is restored, often automatically. This automatic operation is key for ensuring truly hands-off backup power when you need it most, allowing your business to continue without manual intervention.

Control Systems and Remote Monitoring

In today's connected world, the capabilities of the control system can significantly enhance the value and usability of a 200kW natural gas generator. Advanced controllers offer features like automatic self-testing, which regularly runs the generator for a short period to ensure it's ready to operate when needed. They can also log performance data, track maintenance intervals based on runtime, and provide detailed diagnostic codes if an issue arises, simplifying troubleshooting. Remote monitoring capabilities, often accessible via a web portal or mobile app, allow you to check the generator's status, view alerts, and even initiate tests from anywhere. This is particularly valuable for facilities with multiple sites or for managers who aren't always on-site. Imagine receiving a text alert the moment your generator starts up during an outage, confirming that your backup power is engaged – that's the peace of mind advanced monitoring provides. These systems can also integrate with Building Management Systems (BMS) for centralized monitoring and control. When evaluating a natural gas generator 200kw, paying close attention to the sophistication and features of its control system and available monitoring options is vital for ensuring easy management, proactive maintenance, and reliable performance over its operational life, ultimately contributing to greater peace of mind.

Seamless Installation: Getting Your 200kW Natural Gas Generator Ready

The installation of a 200kW natural gas generator is a significant project that requires careful planning and execution, typically involving licensed professionals. Proper installation is crucial for safety, reliability, and compliance with building codes and regulations. The first step is site selection and preparation. The generator needs to be placed on a sturdy, level base, often a concrete pad, capable of supporting its substantial weight. It must be located outdoors with adequate clearance for ventilation, exhaust dispersal, and maintenance access, away from windows, doors, and property lines as dictated by local codes, especially regarding noise and emissions. Next is connecting to the natural gas supply. While the fuel source is convenient, ensuring the gas line is appropriately sized to provide the necessary volume and pressure for a 200kW engine is critical. This often requires coordination with the local gas utility and the installation of dedicated piping. Frankly speaking, an undersized gas line can severely impact the generator's ability to start and run under load. The electrical connection involves wiring the generator into the facility's electrical system via an automatic transfer switch (ATS). This complex wiring ensures a safe transition between utility and generator power and typically requires a master electrician. Additional steps include installing the exhaust system (ensuring proper venting and potentially muffling), setting up the control wiring, and connecting any remote monitoring systems. Permitting and inspections are almost always required for an installation of this size to ensure compliance with all relevant safety and building codes.

Site Preparation and Utility Coordination

Detailed site preparation is non-negotiable for a successful installation. This includes not only the concrete pad but also ensuring accessibility for delivery and future maintenance. Consideration must be given to drainage around the site to prevent water buildup, which could damage the generator or its components. Noise is another factor; even with a sound-attenuated enclosure, strategic placement can further minimize the impact on surrounding areas. Utility coordination is particularly important for the natural gas connection. You need to confirm that the existing gas meter and supply line are sufficient for the generator's fuel requirements at peak demand. If not, upgrades to the meter, regulator, or piping may be necessary, which can take time and require planning with the utility company well in advance. Similarly, coordinating the electrical hookup with the power utility might be necessary if the installation involves complex tie-ins or upgrades to the main service panel. Proper planning with all involved parties – generator supplier, installer, electrician, plumber, and utility companies – is essential to ensure the installation of your natural gas generator 200kw proceeds smoothly, safely, and on schedule, minimizing disruption to your operations and guaranteeing the system is ready to perform when called upon.

Maintaining Peak Performance of Your 200kW Generator

Like any complex piece of machinery, a 200kW natural gas generator requires regular maintenance to ensure its reliability and longevity. Skipping maintenance is a gamble you simply cannot afford to take with critical backup power equipment. A well-maintained generator is far more likely to start and carry the load successfully during an emergency than one that has been neglected. Maintenance schedules are typically based on run hours and calendar time, and your generator's manual will provide specific recommendations. Routine checks should include inspecting fluid levels (oil, coolant), checking for leaks, inspecting belts and hoses, and ensuring the air intake and exhaust are clear of obstructions. The engine oil and filters need to be changed periodically, similar to a vehicle engine, though the interval will depend on the generator's usage. The fuel system, ignition system (spark plugs, etc.), and cooling system also require regular inspection and servicing. Interestingly enough, exercising the generator regularly – running it under load for a set period, typically weekly or monthly – is a crucial maintenance practice. This helps keep the engine and components lubricated, burns off moisture in the exhaust system, and confirms that the transfer switch is functioning correctly. Many modern control systems have built-in exercise functions, making this easy to schedule and monitor.

Scheduled Servicing and Support

While some routine checks can be performed by on-site personnel, more in-depth servicing should be conducted by qualified technicians with experience in servicing industrial generators, specifically natural gas models. Scheduled service visits typically involve comprehensive inspections, adjustments, and replacements of wear items according to the manufacturer's recommendations. Technicians can identify potential issues before they lead to failure, such as worn belts, failing batteries, or unusual engine noises. They also have specialized tools and diagnostic equipment to ensure the generator is running optimally. Having a service contract with a reputable provider is highly recommended for a natural gas generator 200kw. A service contract typically includes regular scheduled maintenance visits, priority response during emergencies, and access to expert technical support. It provides peace of mind knowing that your critical backup power system is being professionally cared for. In my experience, investing in preventative maintenance is always cheaper and less stressful than dealing with a generator failure during a real power outage. Ensuring you have access to readily available parts and knowledgeable support is also crucial; ask your provider about their parts inventory and technician availability when considering a service plan or choosing a generator supplier.

Selecting the Ideal 200kW Natural Gas Generator for Your Needs

With various manufacturers and models available, selecting the right natural gas generator 200kw requires careful consideration of several factors beyond just the power rating and fuel type. Start by evaluating the reputation and track record of the generator manufacturer. Look for companies with a history of producing reliable, durable industrial-grade equipment. Consider the quality of the components used, particularly the engine and alternator, as these are central to the generator's performance and lifespan. Beyond the basic specifications, look at features that add value, such as advanced control panels, sound-attenuated enclosures, weatherproofing, and any available options for paralleling units if future capacity expansion might be needed. Support and service are equally important. Does the manufacturer or their distributor have a strong support network in your area? What kind of warranty is offered? What are the terms of available service contracts? These factors are critical for ensuring that you not only purchase a quality product but also have the necessary support to keep it running reliably for years to come. Why is this approach so effective? Because the cheapest generator upfront may end up being the most expensive in the long run due to maintenance issues, lack of support, or premature failure. Investing in a quality unit with solid support provides the best return on investment in terms of reliability and peace of mind.

Evaluating Manufacturers and Features

When comparing different 200kW natural gas generator options, dig into the specifics provided by each manufacturer. Compare engine details: Is it a dedicated natural gas engine or a modified diesel engine? What is its fuel efficiency? How is the cooling system designed for reliable operation in your climate? Look at the alternator's capabilities, including its ability to handle motor starting loads (transient response) and maintain stable voltage and frequency. Compare the control system features – ease of use, level of monitoring, communication options. Is the enclosure designed for your specific environment (e.g., coastal areas requiring enhanced corrosion protection)? What is the decibel rating of the enclosure? For a commercial natural gas generator, noise levels can be a significant factor depending on its location. Also, consider the total cost of ownership, which includes the initial purchase price, installation costs, estimated fuel costs, and long-term maintenance expenses. Gathering quotes from multiple reputable suppliers and comparing the detailed specifications, features, warranty, and service offerings side-by-side is essential. Don't hesitate to ask for references from businesses in similar industries or with similar power requirements. Our company can provide detailed specifications and comparisons for 200kW natural gas generator options, helping you navigate these technical details to make an informed decision that best suits your operational requirements and budget, ensuring you get a generator you can truly rely on.

Environmental Considerations and Compliance

Operating a natural gas generator 200kw involves adhering to various environmental regulations, primarily concerning air emissions and noise levels. While natural gas burns cleaner than diesel, generator emissions are still regulated in many jurisdictions. Compliance requirements vary significantly by location, often depending on national, state, and local air quality standards. You may need to obtain permits before installing and operating the generator, and ongoing compliance might involve regular emissions testing and reporting. It's crucial to understand the specific regulations applicable to your site early in the planning process, as they can influence the required generator specifications, installation procedures, and ongoing operational costs. Manufacturers design generators to meet various emission standards (e.g., EPA standards in the United States), but verifying that a specific model is compliant in your area is your responsibility. Noise pollution is another significant consideration, particularly in urban or suburban settings. Local ordinances often specify maximum permissible noise levels at property boundaries. While sound-attenuated enclosures are standard for commercial generators, their effectiveness varies. Site selection, strategic placement, and potentially additional sound barriers may be necessary to meet local noise regulations. Understanding these environmental and regulatory requirements upfront is essential for a smooth installation and compliant operation, avoiding potential fines or operational restrictions down the line.

Navigating the complexities of environmental permits and compliance can seem daunting, but it is a critical step in the process of acquiring and operating a natural gas generator 200kw. Regulations are constantly evolving, and what was acceptable yesterday may not be today. Factors such as the generator's intended use (standby or prime power), annual operating hours, and the specific air quality zone your facility is located in can all impact the required permits and compliance measures. Some areas may require the use of specific technologies, such as catalytic converters, to further reduce emissions, even on natural gas units. Additionally, there may be reporting requirements on fuel usage and operating hours. Engaging with local authorities and environmental consultants early in your project can help identify all applicable regulations and ensure your generator purchase and installation plan accounts for everything necessary for compliance. It's also important to consider how future regulatory changes might impact your generator's operation over its lifespan. While natural gas generators offer inherent environmental advantages, proactive planning and attention to detail regarding compliance are key to avoiding unforeseen issues and ensuring long-term, trouble-free operation, allowing you to focus on the core needs of your business.

Conclusion: Securing Your Operations with a 200kW Natural Gas Generator

Choosing a natural gas generator 200kw is a strategic decision for businesses and institutions that require reliable, substantial backup power. The advantages of natural gas as a fuel source – convenience of pipeline delivery, cleaner emissions profile, and potential cost savings – make it a highly attractive option compared to traditional diesel generators for many applications. The 200kW capacity itself is well-suited for a wide range of medium-to-large commercial, institutional, and light industrial needs, providing the power necessary to keep critical operations running smoothly during utility outages. From ensuring patient care in healthcare facilities to preventing data loss in IT centers and maintaining production in manufacturing plants, a properly sized and installed 200kW unit offers peace of mind and protects against significant financial losses and operational disruption. Key considerations when selecting a unit include the quality of the engine and alternator, the sophistication of the control system and monitoring options, the effectiveness of the enclosure, and the availability of reliable service and support. Don't forget the importance of professional installation, regular maintenance, and adherence to environmental regulations to ensure optimal performance and longevity of your investment. By carefully assessing your load requirements, understanding the features that matter, and partnering with a reputable supplier, you can confidently select and deploy a 200kW natural gas generator that provides the dependable backup power your operations require, safeguarding against the uncertainties of the grid and ensuring business continuity no matter what. If you're ready to explore the possibilities and determine the best natural gas generator solution for your specific needs, taking the next step to consult with experts is crucial.

For more detailed information, please visit our official website: natural gas generator 200kw