In a world increasingly reliant on uninterrupted power, the need for dependable backup or primary power sources has never been more critical. From ensuring business continuity during unexpected outages to powering remote operations far from the grid, the demand for robust and reliable electrical generation is constant. Among the various solutions available, the **diesel generator set**, often simply called a **diesel genset**, stands out as a cornerstone of resilient power supply across countless industries and applications. It's a technology that, frankly speaking, has proven its mettle over decades, providing consistent performance when it matters most. But what exactly makes a diesel genset such a go-to solution for critical power needs? Let's dive in and explore the ins and outs of these essential machines.

Unpacking the Fundamentals of a Diesel Genset

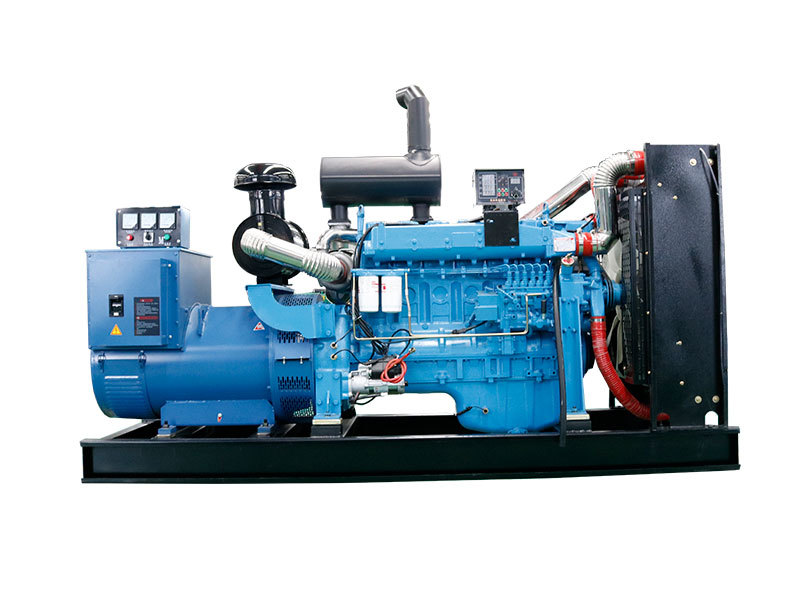

At its core, a diesel generator set is a sophisticated integration of several key components working in harmony to produce electricity. Think of it as a power plant in a box, designed for specific output requirements. The heart of the system is, of course, the diesel engine. This engine converts the chemical energy stored in diesel fuel into mechanical energy through combustion. This mechanical energy, usually rotational force, is then fed into the second crucial component: the alternator, also known as the generator head. The alternator is essentially an electrical generator that uses electromagnetic induction to convert the mechanical energy from the engine into electrical energy, ready to power your lights, machinery, or essential systems. It's worth noting that the quality and efficiency of both the engine and the alternator significantly impact the overall performance and longevity of the genset. Alongside these major players are essential supporting systems, including a fuel tank to supply the diesel, a cooling system to manage the heat generated by the engine, a lubrication system for smooth operation, and crucially, a control panel. This panel acts as the brain, monitoring various parameters, managing output, and often providing automated start/stop functionality, especially in standby applications. Understanding these fundamental parts helps appreciate the engineering behind a reliable power source.

Why Diesel? Evaluating the Advantages and Considerations

Choosing a power source involves weighing various factors, and diesel engines offer a compelling set of advantages that explain their widespread adoption in generator sets. Perhaps the most cited benefit is their inherent reliability and durability. Diesel engines are known for their robust construction and ability to handle heavy loads for extended periods, making them ideal for both standby and continuous power applications. They also tend to be more fuel-efficient than equivalent gasoline engines under similar load conditions, potentially leading to lower running costs, particularly for systems that operate for many hours. The fuel itself, diesel, is less flammable than gasoline, which can be an advantage in terms of storage safety. Furthermore, diesel engines generally require less maintenance compared to gasoline engines, primarily because they don't have a spark ignition system; combustion occurs simply through compression and the introduction of fuel. However, it wouldn't be fair to ignore the considerations. Diesel gensets can be noisier than some other types of generators, though modern enclosures and sound attenuation technologies have significantly mitigated this. Emissions, particularly NOx and particulate matter, are another environmental concern, although engine manufacturers are continuously developing cleaner technologies to meet increasingly stringent regulations. The cost of diesel fuel can also fluctuate, impacting operational budgets. Despite these considerations, the combination of power density, efficiency, and sheer reliability makes diesel gensets a preferred choice for critical power needs.

Diverse Applications: Where Diesel Gensets Shine

The versatility of the diesel generator set means you'll find them powering operations in an incredibly diverse range of environments and industries. Their ability to provide robust, independent power makes them indispensable where grid power is unreliable, unavailable, or insufficient. Construction sites, for instance, frequently rely on portable or trailer-mounted diesel gensets to power tools, lighting, and temporary facilities before grid connection is established. In the healthcare sector, hospitals and clinics depend on standby diesel generators as a life-saving backup power source to ensure critical equipment like life support systems, operating rooms, and essential lighting remain operational during grid failures. Data centers, which require continuous, high-quality power to prevent costly downtime and data loss, are another major user of diesel gensets for reliable backup. Beyond these, they are essential for powering remote mining operations, agricultural facilities, telecommunications towers, emergency services, and even large-scale events or film productions requiring temporary power. Frankly speaking, almost any operation that cannot afford to lose power, or needs power in an off-grid location, is a potential application for a diesel generator set. The scale can vary dramatically, from small units powering a single facility to massive systems capable of backing up entire buildings or complexes. This widespread adoption across critical sectors underscores their proven capability.

Industrial Diesel Generators: Powering Critical Infrastructure

When we talk about powering essential services and large-scale operations, the focus often shifts to **industrial diesel generators**. These aren't your average backup units; they are heavy-duty workhorses designed for demanding applications, often requiring continuous or long-duration standby power. Industrial gensets are typically built with more robust components, larger fuel tanks (or connections to external tanks), advanced cooling systems, and sophisticated control panels compared to smaller residential or commercial units. They are engineered to operate reliably under harsh conditions and often power critical infrastructure like manufacturing plants, oil and gas facilities, water treatment plants, airports, and large commercial buildings. The power output of industrial units can range from several hundred kilowatts to multiple megawatts, often involving paralleling multiple gensets for even greater capacity and redundancy. Reliability is paramount in these settings, as power loss can lead to significant financial losses, safety hazards, or disruption of essential services. Choosing the right industrial diesel generator involves detailed power studies and understanding the specific load requirements, including transient loads, harmonic distortion limits, and voltage regulation needs. These systems represent a significant investment, but their ability to ensure operational continuity makes them invaluable assets in the industrial landscape.

Key Factors in Choosing the Right Diesel Generator Set

Selecting the appropriate diesel genset for a specific application is a critical decision that requires careful consideration beyond just the price tag. One of the most fundamental factors is determining the correct size, typically measured in kVA (kilovolt-amperes) or kW (kilowatts). Oversizing can lead to inefficient operation and potential engine issues (like 'wet stacking'), while undersizing will result in the generator being unable to handle the connected load, potentially causing shutdowns or damage. A thorough load assessment is essential, identifying all the equipment that needs to be powered, their starting (surge) and running power requirements, and whether the load is single-phase or three-phase. Other important considerations include the application type – is it for standby power, prime power (main source), or continuous power? This affects duty cycle and required features. Environmental factors like altitude and ambient temperature can impact a generator's performance and must be accounted for. Noise levels are often a concern, particularly in residential or urban areas, making the type of enclosure (open frame, sound-attenuated, weather-proof) a key decision point. Frankly speaking, navigating these technical specifications and matching them to your unique needs is vital. Many factors contribute to **choosing the right diesel generator set**, and expert guidance can be invaluable in making an informed decision that ensures reliable, long-term performance.

Mastering Diesel Generator Maintenance for Longevity

Much like any complex machinery, a diesel generator set requires diligent and regular maintenance to ensure its reliability and extend its lifespan. Skipping maintenance is a common mistake that can lead to unexpected failures, costly repairs, and shortened equipment life. A comprehensive **diesel generator maintenance** program typically includes routine checks and preventive measures. This involves regularly checking fluid levels – engine oil, coolant, and fuel. The quality of the fuel is surprisingly critical; stale or contaminated fuel can cause significant problems, which is why fuel polishing and storage management are sometimes necessary. Regular replacement of filters – oil filters, fuel filters, and air filters – is also essential to keep the engine running cleanly and efficiently. Load testing, where the generator is run under load for a specified period, is a crucial step, especially for standby units, to ensure it will perform as expected when needed. This helps identify potential issues before an emergency arises. Checking the battery is also vital, as a genset that fails to start due to a dead battery is useless, regardless of engine condition. Keeping detailed logs of all maintenance activities helps track service intervals and identify any recurring issues. Investing in proper maintenance is not just about fixing problems; it's a proactive approach to preventing failures and maximizing the return on your generator investment. Have you ever wondered just how much a simple fluid check can save you in potential downtime and repair costs? It's substantial.

Ensuring Peak Performance and Reliability

Beyond regular maintenance, achieving peak performance and long-term reliability from your diesel generator set involves several other critical factors. Proper installation by qualified technicians is paramount. Incorrect wiring, inadequate ventilation, or improper exhaust routing can compromise safety and performance. The quality of the components themselves makes a huge difference. Choosing a generator set built with reputable engine brands and high-quality alternators ensures a higher level of performance and durability. Factory testing and commissioning are also crucial steps. A generator should be thoroughly tested under various load conditions before being put into service to verify it meets specifications and operates correctly. For critical applications, features like automatic transfer switches (ATS) that seamlessly switch power from the grid to the generator during an outage are essential for uninterrupted operation. Redundancy, such as having multiple smaller generators instead of one large one, or N+1 configurations, can provide an extra layer of reliability for mission-critical facilities. In my experience, partnering with a supplier or service provider who understands the intricacies of generator systems and can offer ongoing support, remote monitoring, and preventive maintenance contracts is invaluable for ensuring your genset is always ready to perform when called upon. Reliability isn't just a feature; it's the core promise of a diesel generator set, and achieving it requires attention to detail at every stage.

The Future and Evolving Landscape of Diesel Gensets

While diesel generators have been a workhorse for decades, the technology and the context in which they operate are constantly evolving. Environmental regulations regarding emissions are becoming stricter globally, pushing manufacturers to develop cleaner engines, utilize advanced after-treatment systems, and explore alternative fuels. Biodiesel blends, for example, are becoming more common, offering a renewable component to the fuel mix. Furthermore, advancements in control systems and digital technology are bringing increased intelligence to diesel gensets. Remote monitoring capabilities allow operators to check the status, performance, and maintenance needs of a genset from afar, improving response times and optimizing service schedules. Integration with renewable energy sources, such as solar or wind power, is another growing trend. Diesel gensets can act as reliable backup or supplemental power sources in hybrid systems, ensuring power continuity even when renewable sources are intermittent. Interestingly enough, while other power generation technologies are emerging, the sheer power density, reliability, and established infrastructure for diesel fuel mean that diesel generator sets are likely to remain a vital part of the power landscape for the foreseeable future, particularly for critical and high-power applications, even as they become more efficient and environmentally conscious.

Common Troubleshooting Tips and When to Seek Help

Even with the best maintenance, generators can occasionally encounter issues. Knowing some basic troubleshooting steps can sometimes save you time and a service call. If a diesel genset fails to start, check the fuel level – sounds simple, but it's a common oversight. Ensure the battery is charged and the connections are clean and tight. Check the control panel for any error codes or indicators. Sometimes, a tripped breaker on the generator itself or in the transfer switch system might be the cause of no power output. If the generator starts but produces unstable voltage or frequency, check the load – is it within the generator's capacity? Are there any unusual noises or vibrations? While these basic checks can be helpful, it is absolutely crucial to know when to call in the professionals. For any issue involving the engine's internal components, the alternator, or complex electrical faults, it is best to rely on qualified technicians. Working with high voltage electricity and complex mechanical systems is dangerous without the proper training and tools. Attempting repairs beyond your expertise can cause further damage to the generator or, more importantly, pose a serious safety risk. Relying on experienced service providers ensures that issues are diagnosed and fixed correctly and safely, restoring your generator's reliability quickly.

Partnering for Reliable Power Solutions

Understanding the nuances of diesel generator sets, from their basic components and types to the critical importance of proper selection and ongoing maintenance, highlights the complexity involved in ensuring truly reliable power. Whether you need backup power for a small business, prime power for an off-grid location, or robust **industrial diesel generators** for critical infrastructure, getting it right is essential. Our company specializes in providing comprehensive power solutions tailored to your specific requirements. We offer a wide range of high-quality diesel gensets designed for various applications, from compact residential units to powerful industrial systems. Our expertise extends beyond just supplying equipment; we provide in-depth consultation to help you assess your power needs and assist with **choosing the right diesel generator set**, ensuring optimal performance and efficiency. Furthermore, we offer professional installation services and comprehensive **diesel generator maintenance** programs designed to maximize the lifespan and reliability of your investment. We understand that reliable power is non-negotiable for many operations, and our goal is to provide solutions that give you peace of mind, knowing your power needs are covered, no matter the circumstances. Don't leave your power security to chance; partner with experts who can deliver the reliable power you need.

In conclusion, the diesel generator set remains a powerful, reliable, and versatile solution for a vast array of power generation needs. While the technology continues to evolve, its fundamental strength lies in its ability to provide robust power precisely when and where it's required. From preventing downtime in critical facilities to enabling operations in remote areas, the role of the diesel genset is undeniable. Navigating the options, ensuring correct installation, and committing to a rigorous maintenance schedule are key to unlocking the full potential and longevity of these essential machines. Investing in a quality diesel generator set and partnering with knowledgeable professionals ensures that you have a dependable power source ready to perform when called upon, safeguarding your operations and assets against the unpredictability of power supply. Reliable power is not a luxury; it's a necessity, and a well-chosen and maintained diesel generator set delivers just that.

For more detailed information, please visit our official website: Diesel generator set