In today's interconnected and highly automated world, relying solely on the main power grid can be a significant vulnerability for businesses, institutions, and even large residential properties. Power outages, whether brief flickers or prolonged blackouts caused by weather, grid instability, or unforeseen events, can disrupt operations, lead to substantial financial losses, compromise safety, and damage reputation. For many critical applications, particularly those requiring a robust and reliable source of backup electricity, a substantial power generation solution is not just an option; it's an absolute necessity. This is precisely where a **standby generator 250kVA** comes into play, offering the capacity and performance required to keep essential systems running smoothly when the grid fails. Understanding the capabilities and requirements of a generator of this size is the first step towards ensuring continuous, uninterrupted power flow, safeguarding against the unpredictability of external power sources and maintaining operational integrity.

Why, you might ask, is a 250kVA unit often the specific choice for many organizations? It boils down to power demand and the specific needs of the facility. A 250 kilovolt-ampere (kVA) generator is a powerful machine, capable of providing approximately 200 kilowatts (kW) of usable power (assuming a typical power factor of 0.8). This capacity is generally insufficient for small offices or homes, but it's perfectly suited for a wide range of medium-to-large scale applications. Think data centers that cannot afford a single second of downtime, hospitals where life support systems depend on continuous power, manufacturing plants that need to maintain production lines, large retail complexes, or critical infrastructure like water treatment facilities or telecommunications hubs. These environments have significant power requirements for lighting, HVAC, critical equipment, and IT systems, and a 250kVA unit often strikes the ideal balance between power output, physical footprint, fuel efficiency, and cost for these scenarios. Frankly speaking, correctly sizing a generator is paramount, and for many substantial operations, 250kVA represents the sweet spot that ensures all critical loads, and potentially some non-critical ones, remain powered.

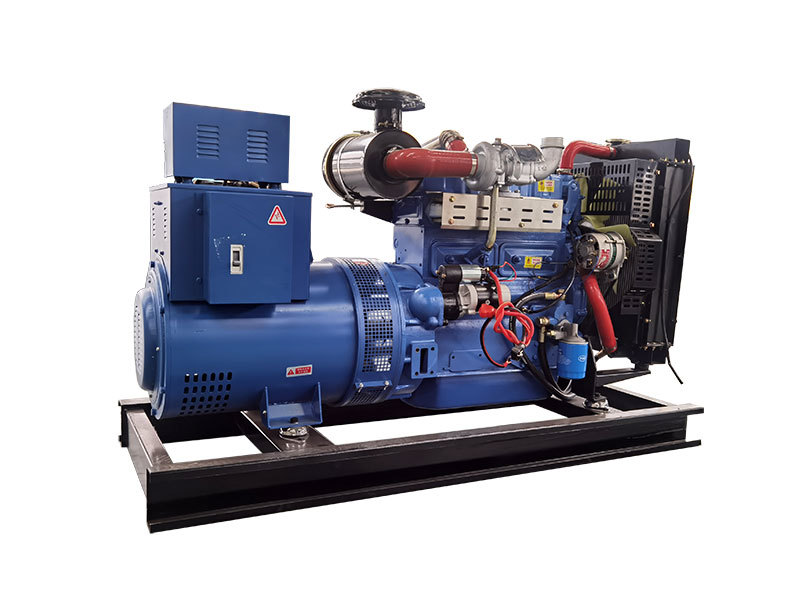

Understanding the Anatomy of a 250kVA Generator

Delving into the core of what makes a **standby generator 250kVA** function reveals several key components working in harmony. At its heart is the engine – typically a robust, industrial-grade diesel or natural gas engine designed for reliable operation under load for extended periods. Diesel engines are renowned for their durability, fuel efficiency under heavy load, and readily available fuel storage options, making a **250kVA diesel generator** a popular choice for backup power. Coupled with the engine is the alternator, which converts the engine's mechanical energy into electrical energy. The quality and design of the alternator are crucial for stable voltage and frequency output, essential for protecting sensitive electronic equipment. Then there's the control panel, the brain of the operation, monitoring engine parameters, managing starting and stopping sequences, and often featuring advanced diagnostics and communication capabilities. Lastly, the automatic transfer switch (ATS), which we'll discuss further, is the component that makes it a "standby" generator, automatically sensing a power outage and initiating the generator start sequence.

Beyond the main components, several other elements contribute to the overall performance and reliability of a 250kVA system. The cooling system, usually radiator-based, is vital for maintaining optimal engine temperature during operation. The fuel system, including tanks, pumps, and filters, must be designed to supply the engine with a consistent and clean fuel supply. For diesel units, proper fuel maintenance is crucial to prevent issues like microbial growth or filter clogging. The exhaust system, which includes mufflers and piping, is essential for directing harmful fumes away from the facility and often incorporates noise reduction technologies to meet local regulations. Furthermore, the base frame provides structural support and often integrates vibration isolation to minimize noise and wear. Understanding these interconnected systems helps appreciate the engineering complexity behind a reliable backup power solution of this magnitude and highlights why professional installation and maintenance are non-negotiable.

Planning for Installation: More Than Just Plugging In

Installing a **standby generator 250kVA** is a complex undertaking that requires careful planning and execution. It's far more involved than simply placing the unit outside and connecting a few wires. Proper site selection is critical; the location must be accessible for maintenance and fuel delivery, meet setback requirements from buildings and property lines, and consider noise emissions. The ground must be stable enough to support the significant weight of the generator, often requiring a reinforced concrete pad. Fuel storage is another major consideration, especially for diesel units, requiring appropriately sized and located tanks that meet safety and environmental regulations. The electrical connection involves integrating the generator output seamlessly with the building's electrical system via the ATS, which is a task for licensed electricians. Exhaust routing must be carefully planned to ensure fumes are safely dispersed. In my experience, overlooking any of these factors during the planning phase can lead to costly problems down the line, from code violations to operational issues.

Environmental factors and noise are also significant considerations when planning for a 250kVA generator installation. These units are powerful machines, and their operation generates both heat and noise. While manufacturers incorporate sound attenuation measures, such as acoustically treated enclosures, the noise level can still be a concern, particularly in urban or residential areas. Compliance with local noise ordinances is essential, and additional soundproofing or strategic placement might be necessary. Similarly, exhaust emissions must meet relevant environmental standards. Choosing a unit that complies with the latest emissions regulations is important. Furthermore, managing heat dissipation from the radiator requires adequate airflow around the unit. Proper planning includes assessing these factors and implementing appropriate solutions, often involving working with experienced engineers and installers familiar with the intricacies of integrating large backup power systems into various environments. It's worth noting that regulations vary significantly by location, adding another layer of complexity to the planning process.

Fueling Your Backup: Diesel vs. Natural Gas

When considering a 250kVA standby generator, the choice of fuel source is one of the primary decisions, with diesel and natural gas being the most common options for this size. Each has its distinct advantages and disadvantages. Diesel generators are known for their robust performance under heavy loads, quick starting capabilities, and fuel efficiency when running for extended periods, especially for emergency backup where they might run infrequently but need to perform reliably when called upon. Diesel fuel can be stored on-site, providing independence from external fuel supply lines during a widespread outage. However, diesel fuel requires regular testing and potential treatment to prevent degradation and contamination, and its storage is subject to environmental regulations. Emissions from diesel engines are also a consideration, though modern engines are significantly cleaner than older models.

Natural gas generators, on the other hand, offer the advantage of a continuous fuel supply via the utility pipeline, eliminating the need for on-site storage and the associated maintenance and regulatory burdens. They typically produce fewer emissions than diesel generators and can be quieter in operation. However, their starting capability can sometimes be less immediate than diesel, and performance might slightly decrease under extremely heavy loads compared to a comparably sized diesel unit. Reliance on the natural gas pipeline also means that an outage affecting both the electrical grid and the gas supply (though less common) could render the generator inoperable. The choice between diesel and natural gas for a 250kVA unit often depends on factors like local fuel availability and cost, environmental regulations, site constraints for fuel storage, and the specific operational requirements and run time expectations of the backup power system. It's a decision that warrants careful analysis of your facility's unique needs and circumstances.

The Critical Role of the Automatic Transfer Switch (ATS)

For a generator to truly function as a "standby" system, providing seamless backup power without manual intervention during an outage, an Automatic Transfer Switch (ATS) is absolutely indispensable. Think of the ATS as the conductor orchestrating the transition between utility power and generator power. When the ATS detects a loss of utility power, it waits a predetermined brief period (to confirm the outage isn't just a momentary fluctuation), signals the standby generator to start, and once the generator reaches its stable operating voltage and frequency, the ATS safely disconnects the building's electrical load from the utility grid and connects it to the generator. When utility power is restored and stable, the ATS transfers the load back to the utility and signals the generator to shut down after a cool-down period. This process happens automatically, typically within seconds or minutes depending on the configuration, ensuring minimal disruption to critical operations.

Without an ATS, a standby generator would require manual operation – someone would have to be on-site to detect the outage, start the generator, and manually switch the power source, which is impractical and can lead to significant downtime. Moreover, attempting to connect a generator directly to the grid without proper isolation (which the ATS provides) can be extremely dangerous, potentially backfeeding power onto the grid and posing a severe hazard to utility workers. For a substantial system like a 250kVA standby generator, the ATS must be appropriately rated for the facility's electrical load and fault current capacity. Different types of ATS exist, including open transition (brief break in power during transfer), closed transition (momentary parallel operation), and delayed transition, each suited for different applications and power sensitivity requirements. Selecting the right ATS is as crucial as choosing the generator itself for ensuring safe, reliable, and automatic backup power.

Maintenance: The Key to Uninterrupted Reliability

Investing in a **standby generator 250kVA** is a significant commitment aimed at ensuring power reliability. However, this investment only pays off if the generator is ready to perform flawlessly when needed. This readiness is solely dependent on a rigorous and proactive maintenance schedule. Generators are complex machines with engines, electrical components, and control systems that require regular attention, even when they are just sitting idle in standby mode. Routine maintenance includes scheduled inspections, fluid checks and changes (oil, coolant), filter replacements (fuel, air, oil), battery checks (ensuring the starting battery is charged and healthy), and visual inspections of connections, hoses, and belts. Fuel quality management is particularly important for diesel units to prevent issues that can lead to starting failures or poor performance.

Beyond basic checks, regular load testing is a critical part of maintaining a 250kVA standby generator. Load testing involves running the generator under a significant electrical load for a set period. This practice serves several purposes: it burns off carbon deposits in the engine (especially important for units that run infrequently), verifies that the generator can produce its rated power output, and confirms that all components function correctly under working conditions. Many experts agree that monthly or quarterly load tests, depending on the application and generator type, are essential. Frankly speaking, skipping or postponing maintenance might save money in the short term, but it drastically increases the risk of generator failure during an actual power outage, completely defeating the purpose of having a standby system. A professional maintenance contract with a qualified service provider is highly recommended for a generator of this size and importance.

Choosing the Right 250kVA Solution Provider

Acquiring and implementing a **standby generator 250kVA** system involves more than just purchasing the equipment; it requires partnering with a knowledgeable and reliable provider. The complexity of sizing the unit correctly, navigating installation requirements (including local codes and permits), and ensuring ongoing maintenance necessitates expertise. When evaluating potential providers, look for a company with a proven track record specifically with larger generator systems. They should be able to assist with a thorough load analysis of your facility to ensure the 250kVA size is indeed appropriate or recommend adjustments if necessary. Their experience in installing similar systems will be invaluable in addressing site preparation, fuel storage, exhaust, and electrical integration challenges. A good provider will also have experienced technicians capable of performing both the initial installation and crucial ongoing maintenance and repair services.

Furthermore, consider the level of ongoing support offered. A reliable provider should offer comprehensive service contracts, including scheduled preventative maintenance visits and 24/7 emergency repair services. Ask about their typical response times, especially during widespread outages when demand for generator service spikes. Warranty coverage on both the generator unit and the installation work is also an important factor. Communication and transparency are key; you want a partner who can clearly explain the system, the installation process, maintenance requirements, and any potential challenges. Ultimately, selecting the right provider is about building a long-term relationship with experts you can trust to keep your critical power protection system functioning perfectly, ensuring peace of mind knowing that your operations are safeguarded against grid failures. This is where our company's expertise comes into play, guiding clients through every step from selection to ongoing support.

Applications Where 250kVA Makes the Difference

Interestingly enough, the applications requiring a 250kVA standby generator are diverse but share a common thread: the need for significant, reliable power backup to prevent critical disruption. Hospitals and healthcare facilities, for instance, depend entirely on backup power to maintain operating rooms, life support equipment, and essential patient care systems during outages. Data centers rely on units this size (and often much larger) to ensure continuous power to servers and cooling systems, protecting invaluable data and maintaining online services. Manufacturing plants use 250kVA generators to power production lines, preventing costly shutdowns, damage to equipment, or spoilage of materials. Large retail stores or shopping centers might use them to keep lighting, security systems, HVAC, and refrigeration running, avoiding lost sales and security risks. Critical infrastructure like pumping stations for water or wastewater treatment also require substantial backup to maintain essential public services.

Beyond these common examples, many other sectors benefit significantly from the capabilities of a 250kVA unit. Telecommunications facilities need uninterrupted power for network equipment. Educational institutions like universities might use them to power dormitories, labs, or critical research facilities. Large office buildings often require them to keep essential systems, including elevators, security, and core IT infrastructure, operational. Even large residential estates with extensive power demands for automation, climate control, and security might find a 250kVA unit necessary. Have you ever wondered how these critical services stay operational during major storms or grid failures? Often, it's thanks to a properly sized and maintained standby generator like a 250kVA system. Understanding the specific power needs and critical loads of your facility is paramount to determining if this is the right size solution for your application.

Beyond Power: Features and Options for 250kVA Systems

Modern 250kVA standby generators come with a range of features and options that enhance their functionality, reliability, and ease of management. Remote monitoring capabilities, for instance, allow operators to check the generator's status, receive alerts, and even initiate tests from off-site, crucial for facilities with limited on-site staff or multiple locations. Advanced control panels offer detailed diagnostics, event logs, and programmable exercise schedules. Sound-attenuated enclosures are standard for most installations, significantly reducing noise levels to comply with regulations and minimize disruption. Cold weather kits, including block heaters and battery blankets, ensure reliable starting in low temperatures. Automatic fuel transfer systems can pull fuel from a remote tank. Emissions control technologies are also becoming increasingly sophisticated to meet stricter environmental standards.

Furthermore, options like paralleling capabilities allow multiple generators to work together to meet higher load demands or provide redundancy. This means a facility could potentially use two smaller generators (e.g., two 150kVA units) paralleled to meet a 250kVA+ load, offering increased flexibility and reliability (if one unit fails, the other can still carry a portion of the load). Transfer switch options, as mentioned earlier, can be customized based on the required transition type and the complexity of the electrical system. Surge protection is often integrated to safeguard the generator and connected equipment from voltage spikes. To be honest, the specific features and options chosen for a 250kVA system should be carefully considered based on the application's unique needs, operational environment, and budget. Working with an experienced provider helps navigate these choices to build a system that is not only powerful but also smart, reliable, and compliant.

Ensuring Long-Term Performance and Value

The long-term value of a 250kVA standby generator is directly tied to its consistent readiness and operational lifespan. Proper installation, as discussed, is foundational, but diligent ongoing care is what preserves the investment and ensures the generator will perform reliably for years, even decades. This includes adhering strictly to the manufacturer's recommended maintenance schedule, using high-quality replacement parts and fluids, and addressing any alerts or potential issues promptly. Beyond routine service, periodic comprehensive inspections by certified technicians can identify wear and tear before it leads to failure. Keeping detailed service records is also crucial for tracking the generator's history and scheduling future maintenance. Environment plays a role too; protecting the unit from harsh weather and ensuring good ventilation within its enclosure contributes to its longevity.

Investing in training for your staff, if they are responsible for basic checks or responding to alarms, is also a worthwhile endeavor. While professional service is essential for complex tasks, having on-site personnel who understand the system basics can be beneficial. Considering the total cost of ownership, which includes the initial purchase price, installation costs, fuel expenses, and maintenance costs, helps in long-term planning and budgeting. A well-maintained 250kVA generator not only provides reliable backup power but also retains better resale value if it ever needs to be upgraded or replaced. Ultimately, viewing the generator not just as a piece of equipment but as a critical system requiring dedicated care is key to maximizing its performance, ensuring its reliability when you need it most, and protecting your operations effectively against the uncertainties of power availability.

Conclusion: Securing Your Operations with 250kVA

In conclusion, the need for reliable power backup is increasingly critical for a wide array of businesses and institutions. A **standby generator 250kVA** represents a robust and capable solution for facilities with significant power demands that cannot afford downtime. From ensuring patient safety in healthcare facilities and protecting invaluable data in data centers to maintaining production in manufacturing and keeping essential services operational, a 250kVA unit provides the power needed to ride out grid outages seamlessly. Understanding the components, planning the installation meticulously, choosing the right fuel and transfer switch technology, and committing to a rigorous maintenance schedule are all vital steps in deploying a dependable backup power system of this size. Choosing a knowledgeable and experienced provider to guide you through the entire process, from initial load assessment and sizing to installation and long-term service, is arguably the most critical decision you will make. It provides the confidence that your investment is sound and that your operations are truly protected. If your facility's power needs fall within the substantial range that a 250kVA generator can serve, taking the necessary steps to acquire and maintain such a system is a proactive measure that safeguards against disruption and ensures continuity.

For more detailed information, please visit our official website: standby generator 250kva