In today's interconnected world, where everything from our homes to our industries relies heavily on a consistent power supply, the importance of dependable electricity simply cannot be overstated. Power outages, whether caused by severe weather, grid failures, or unforeseen technical issues, can bring daily life to a standstill, halt business operations, and even pose safety risks. This is where the critical role of **Generator Sets** comes into sharp focus. Often seen as silent guardians, these systems are designed to kick into action precisely when the primary power source fails, providing an essential bridge that keeps the lights on, the machinery running, and vital services operational. But what exactly are generator sets, and why are they such an indispensable investment for anyone serious about ensuring continuity and resilience in the face of power disruptions? Frankly speaking, they are far more than just a backup; they are a proactive measure against uncertainty, a fundamental component of modern infrastructure that grants peace of mind by guaranteeing power availability when you need it most. Understanding their function, variety, and application is the first step towards securing this crucial layer of protection, transforming vulnerability into robust independence from external power fluctuations. We've seen firsthand the impact of unexpected outages, and the foresight to have a reliable generator set in place makes all the difference.

Understanding the Core Function and Types of Generator Sets

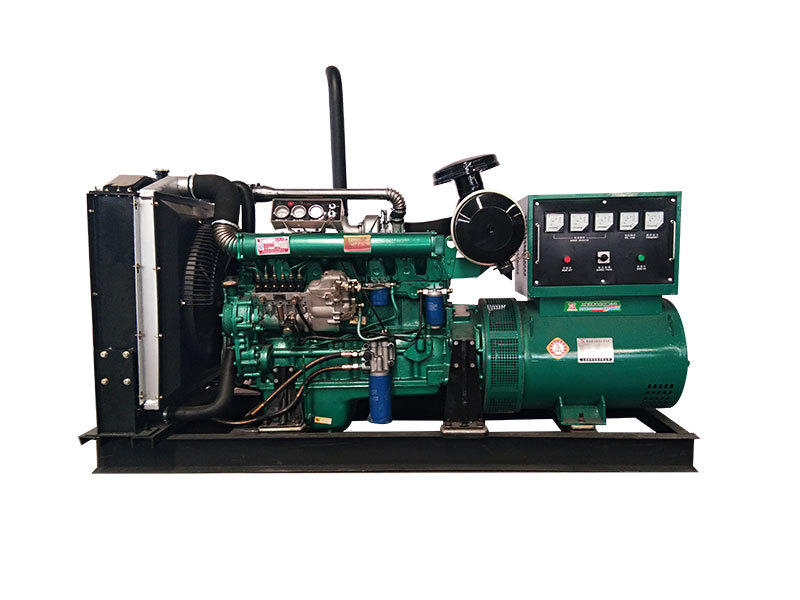

At their heart, a generator set, often abbreviated as genset, is an integrated unit comprising an engine and an electrical generator (often called an alternator) mounted together. The engine burns fuel (like diesel, natural gas, or propane) to create mechanical energy, which then drives the alternator, converting that mechanical energy into electrical power. It's a straightforward principle, but the execution involves sophisticated engineering to ensure reliability and efficiency. Interestingly enough, the sheer variety of generator sets available means there's a solution for almost every need, from powering a small home during an outage to providing the sole power source for a remote industrial site. We primarily encounter several main types based on fuel and application. Diesel generator sets are perhaps the most common, widely known for their robustness, durability, and fuel efficiency, especially in larger applications. They require less maintenance compared to some other types and have a long lifespan, making them a favorite for industrial and commercial **backup power generators**. Natural gas generator sets are popular in residential and commercial settings where natural gas lines are readily available; they are often quieter and produce fewer emissions. Propane gensets offer flexibility as propane can be stored on-site, making them suitable for areas without natural gas infrastructure. The choice of fuel and type heavily influences factors like running costs, environmental impact, and maintenance requirements, making careful consideration essential during the selection process. We guide clients through these options daily, highlighting how different types align with specific operational demands and environmental goals.

Choosing the Right Generator Set: Capacity and Application

Selecting the appropriate generator set is perhaps the most critical decision you'll face, and it's one that requires careful calculation and foresight. A common mistake is underestimating the power requirements, leading to an overloaded generator that could fail when needed most or suffer a significantly shortened lifespan. Conversely, oversizing can lead to unnecessary upfront costs and less efficient operation at lower loads. Determining the correct capacity involves conducting a thorough load assessment. You need to identify all the electrical loads that the generator will need to support simultaneously – lights, appliances, HVAC systems, critical machinery, computers, and any other essential equipment. It's not just about adding up the continuous running watts; you also need to account for starting watts, which can be several times higher for inductive loads like motors. Have you ever wondered why a small generator might power lights but trip when a refrigerator compressor starts? That's often due to insufficient starting power. Beyond capacity, you must consider the intended application. Is it for standby power, running only during grid outages? Or is it for prime power, providing the main electricity source for a location not connected to the grid? Standby generators are typically less expensive for a given capacity but are not designed for continuous running, whereas prime power units are built for endurance. The environment where the genset will operate also matters – altitude, temperature extremes, and humidity can all impact performance. Getting this step right is paramount, and frankly, it's where professional consultation becomes invaluable to ensure long-term satisfaction and reliability from your **Generator Sets**.

Delving into Key Components and Their Significance

Understanding the individual components of a generator set provides crucial insight into its overall function and reliability. While the engine and alternator are the primary players, several other parts are essential for seamless operation. The engine, as mentioned, is the powerhouse, converting fuel into mechanical energy. Its size, type (diesel, gas, etc.), and quality directly impact the generator's capacity, fuel efficiency, and longevity. A robust, well-maintained engine is the backbone of any reliable genset. The alternator, or generator head, is the electrical component that converts the mechanical energy from the engine into usable electrical power. The quality of the windings and design of the alternator influence the stability and purity of the output power, which is particularly important for sensitive electronics. Then there's the fuel system, which includes the fuel tank, lines, and filters, ensuring a clean and consistent supply of fuel to the engine. A often-overlooked but vital component is the control panel. This is the brain of the operation, monitoring parameters like voltage, frequency, engine temperature, and oil pressure. Modern control panels offer advanced features like remote monitoring, automatic start/stop based on power availability (especially when paired with an Automatic Transfer Switch), and diagnostics. Without a functional control panel, the genset cannot operate efficiently or safely. Mufflers and exhaust systems manage noise and emissions, while the cooling system (usually air or liquid) prevents the engine from overheating. Each of these components must work in harmony for the generator set to perform optimally, and any failure in one can compromise the entire system's effectiveness. It's worth noting that the quality and integration of these parts are what truly differentiate reliable **diesel generator sets** from less dependable options.

Installation and Siting: More Than Just Placing the Unit

Proper installation of a generator set is just as critical as selecting the right unit. It's not simply a matter of putting the genset on the ground and hooking up a few wires. The location, foundation, ventilation, exhaust routing, fuel connections, and electrical hookups all require careful planning and execution, often needing compliance with local building codes and electrical standards. Choosing the right site involves considering factors like accessibility for maintenance and fuel delivery, proximity to the electrical load, noise levels, and safety regulations regarding fuel storage and exhaust emissions. The foundation must be level, stable, and capable of supporting the weight of the genset, especially for larger units. Adequate ventilation is crucial to provide the engine with enough air for combustion and prevent overheating; hot exhaust fumes also need to be safely directed away from buildings and vents. Improper ventilation is a common cause of generator performance issues or failure. Fuel storage solutions must be compliant with safety regulations and sized appropriately for the generator's run time requirements. Electrical connections must be performed by qualified electricians, particularly the integration with your existing electrical system and the installation of an Automatic Transfer Switch (ATS) if you desire automatic backup power. Frankly, attempting a DIY installation without the necessary expertise can be dangerous and may even void your warranty. Our company specializes in comprehensive installation services, ensuring that every aspect meets stringent safety and performance standards, providing peace of mind that your generator set is ready when needed.

Essential Maintenance for Peak Performance and Longevity

Like any complex piece of machinery, generator sets require regular and diligent maintenance to ensure they operate reliably when called upon and to maximize their lifespan. Neglecting maintenance is a surefire way to discover your generator isn't ready during a critical power outage. A proactive maintenance schedule is not merely recommended; it's absolutely essential. This typically includes routine checks such as inspecting fluid levels (oil, coolant), checking the fuel system for leaks, inspecting belts and hoses, and examining electrical connections for corrosion or looseness. Filters – fuel, oil, and air – need periodic replacement according to the manufacturer's guidelines. Engine oil also needs changing at specified intervals, as contaminated oil can cause excessive wear. Battery maintenance is particularly important for units with electric start; terminals should be cleaned, connections checked, and battery charge levels verified. A genset that won't start because of a dead battery is useless, regardless of how well the engine or alternator performs. Testing the generator regularly, usually under load, is perhaps the most crucial maintenance step. This ensures that the unit starts reliably and can handle the required load. Many experts agree that weekly or monthly test runs are a minimal requirement for standby units. Keeping detailed records of all maintenance activities, including inspections, repairs, and service dates, helps track the genset's health and identify potential issues before they cause a breakdown. Investing in a professional maintenance contract is often the most practical solution, providing expert care and adherence to schedules, ensuring your generator set remains a dependable asset for years to come.

Diverse Applications Across Various Sectors

The versatility of generator sets makes them indispensable across a wide spectrum of applications, extending far beyond simple emergency home backup. In the residential sector, smaller gensets provide essential power during outages, keeping lights, refrigerators, and essential electronics running, significantly improving comfort and safety. Moving to the commercial realm, businesses rely on generator sets to prevent costly downtime. Retail stores, restaurants, and offices can lose significant revenue and face data loss during power failures. A reliable backup system ensures operations continue uninterrupted, protecting inventory and customer service. For critical facilities like hospitals, data centers, and communication hubs, generator sets are not just a convenience but a life-saving necessity. These institutions require continuous power to maintain essential services, run medical equipment, protect sensitive data, and keep communication lines open. In the industrial sector, large-scale **industrial generators** power manufacturing plants, construction sites, mining operations, and oil and gas facilities, often serving as the primary power source in remote locations or providing critical backup to prevent disruption to complex processes and supply chains. Emergency services, including police, fire departments, and disaster relief organizations, depend heavily on portable and stationary generator sets to power command centers, temporary shelters, and communication equipment in areas affected by disasters where grid power is unavailable. The specific demands of each application necessitate different types and sizes of generator sets, highlighting the importance of tailored solutions to meet unique power requirements and operational challenges effectively.

Considering Integration and Advanced Features

Modern generator sets often integrate seamlessly into existing power systems and offer advanced features that enhance their functionality and ease of use. One of the most significant integration components is the Automatic Transfer Switch (ATS). An ATS is installed between the main power supply (the grid) and the generator set. When the ATS detects a loss of utility power, it automatically signals the generator to start. Once the generator reaches stable voltage and frequency, the ATS transfers the electrical load from the grid to the generator. When grid power is restored, the ATS transfers the load back to the utility and signals the generator to cool down and shut off. This automated process is essential for true standby power, eliminating the need for manual intervention during an outage. For larger installations or facilities with fluctuating power demands, paralleling multiple generator sets can offer significant advantages. Paralleling allows two or more generators to work together, sharing the load. This provides redundancy – if one unit fails, the others can continue to supply power. It also offers scalability; you can add more generators as power needs increase or run only the necessary units during periods of lower demand, improving fuel efficiency. Advanced control systems offer remote monitoring and management capabilities, allowing operators to check the status, performance data, and diagnostic alerts of their generator set from a computer or mobile device. These features are particularly valuable for critical applications or sites where continuous on-site monitoring is impractical. We offer systems that integrate these advanced features, providing our clients with intelligent, reliable, and easy-to-manage power solutions tailored to their specific needs, whether it's for a complex **industrial generator** setup or a simple home backup system.

Troubleshooting Common Issues and Seeking Expertise

Even with diligent maintenance, generator sets can occasionally encounter issues. Knowing how to identify common problems or when to call for professional help is crucial for minimizing downtime. Some frequent issues include failure to start, which can often be traced back to battery problems, fuel issues (low level, clogged filter, old fuel), or control panel errors. Low power output or unstable voltage might indicate issues with the alternator, engine performance, or load calculation errors. Excessive noise or vibration could signal mechanical problems within the engine or generator head. Overheating is another concern, potentially caused by inadequate coolant levels, clogged radiators, or poor ventilation. Black or white smoke from the exhaust can point to engine combustion issues, requiring expert diagnosis. While basic checks like verifying fuel levels, checking the battery connection, and ensuring all switches are in the correct position are steps homeowners or operators can take, attempting complex repairs without proper knowledge can be dangerous and may cause further damage. This is where relying on experienced professionals becomes invaluable. Many issues require specialized diagnostic tools and in-depth understanding of both engine and electrical systems. Instead of guessing or trying fixes that might worsen the problem, it's often more efficient and safer to consult with experts. Our team has encountered and resolved a vast array of generator set issues, from simple fixes to complex overhauls, and we are equipped to diagnose problems accurately and implement effective, lasting solutions, ensuring your generator set is restored to peak operating condition quickly and reliably.

Conclusion: Securing Your Power Future with Generator Sets

In an era where power interruptions carry significant consequences, investing in reliable **Generator Sets** is no longer just a luxury; for many, it's a fundamental necessity. From safeguarding your family's comfort and safety at home to ensuring uninterrupted operations for complex industrial processes, the ability to generate your own power provides an unparalleled level of resilience and independence. We've explored the different types, the critical process of selecting the right capacity and application, the vital roles of key components, the importance of proper installation and siting, the non-negotiable need for regular maintenance, the diverse applications across various sectors, and the benefits of integrated systems and troubleshooting common issues. The journey to securing reliable power involves understanding your needs, choosing a high-quality system, ensuring it's installed correctly, and committing to its ongoing care. Frankly, the peace of mind that comes from knowing you have a dependable backup power source is invaluable. If you're ready to take the next step towards power security, whether you're looking for a home standby unit, a commercial solution, or robust industrial power, we are here to help. Our expertise covers the full spectrum, from initial assessment and selection to professional installation, integration of advanced features, and ongoing maintenance services. Don't wait for the next outage to realize the importance of a generator set; proactive planning today guarantees power when you need it most tomorrow. What steps will you take today to ensure your power future is secure? Contacting experts is a solid starting point.

For more detailed information, please visit our official website: Generator Sets