In a world increasingly reliant on uninterrupted power, the significance of dependable energy sources cannot be overstated. From critical infrastructure to essential business operations, power outages can lead to significant disruptions, financial losses, and even safety hazards. This is where the diesel generator set emerges as a cornerstone of power reliability, offering a robust and readily available solution for backup and prime power needs. Diesel gensets, as they are also commonly known, have become indispensable across diverse sectors, providing a consistent and powerful energy source when grid power falters or is unavailable altogether. Their enduring popularity stems from their proven performance, fuel efficiency, and adaptability to a wide range of applications, making them a trusted choice for ensuring power continuity in a demanding world.

Understanding the Core Components of a Diesel Generator Set

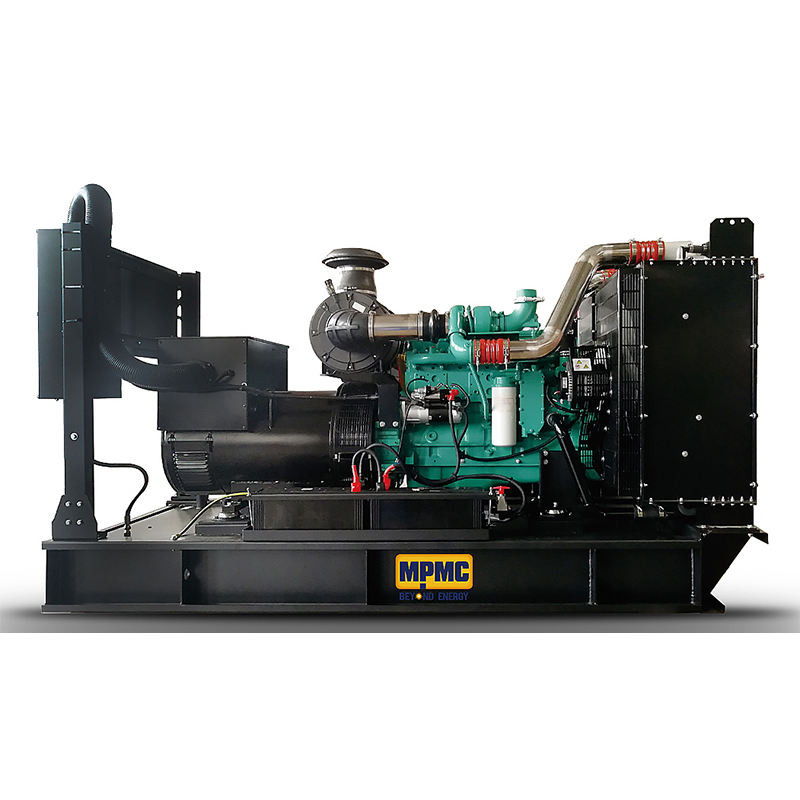

A diesel generator set is more than just an engine; it's a meticulously engineered system comprised of several key components working in harmony to produce electrical power. At its heart lies the diesel engine, renowned for its durability and efficiency in converting fuel into mechanical energy. This mechanical energy is then channeled to the alternator, the electrical generator component, which transforms it into usable electrical energy. The engine and alternator are typically mounted on a sturdy base frame, designed to minimize vibrations and ensure structural integrity. Furthermore, a crucial element is the control system, which monitors and manages the operation of the entire genset, including engine speed, voltage output, and safety parameters. The fuel system, exhaust system, and cooling system are equally vital, each playing a critical role in the efficient and safe functioning of the diesel generator. Understanding these core components is essential to appreciating the sophisticated engineering that underpins the reliability of a diesel genset.

The Diesel Engine: Powering the Genset

The diesel engine is the workhorse of the diesel generator set, and its characteristics largely define the genset's performance and capabilities. Diesel engines are compression-ignition engines, known for their high torque output at lower speeds and superior fuel efficiency compared to gasoline engines, especially under heavy loads. This inherent efficiency translates to lower operating costs over the lifespan of the generator, a significant advantage for businesses and organizations that rely on continuous or frequent backup power. Moreover, diesel engines are built to be incredibly robust and long-lasting, capable of withstanding demanding operating conditions and requiring less frequent maintenance. Manufacturers offer a wide range of diesel engines, varying in size and power output, allowing for the selection of an engine perfectly matched to the specific power requirements of the application, whether it's a small backup system for a home or a large-scale industrial power solution. The reliability and longevity of the diesel engine are fundamental to the overall dependability of the diesel generator set.

The Alternator: Converting Mechanical to Electrical Energy

Following the diesel engine in the power generation process is the alternator, also known as the generator head. This component is responsible for converting the mechanical energy produced by the engine into electrical energy. Inside the alternator, a rotating magnetic field induces an electric current in stationary conductors, a principle of electromagnetic induction. The design and quality of the alternator are critical to the output voltage stability, waveform purity, and overall efficiency of the diesel generator set. Different types of alternators are available, including synchronous and asynchronous types, each with its own characteristics and suitable applications. Factors such as voltage regulation, insulation class, and overload capacity are key considerations when selecting an alternator. A well-matched and high-quality alternator ensures that the diesel genset delivers consistent and clean power, vital for sensitive electronic equipment and demanding industrial machinery alike.

Diverse Applications of Diesel Generator Sets

The versatility of the diesel generator set is a major factor contributing to its widespread adoption across numerous sectors. In healthcare, hospitals rely heavily on diesel gensets to maintain critical life support systems, operating room functionality, and essential medical equipment during power outages. Data centers, the backbone of our digital world, also depend on backup diesel power to prevent data loss and service interruptions. Industries ranging from manufacturing and construction to telecommunications and agriculture utilize diesel generators for both prime and standby power. In remote locations where grid access is limited or non-existent, diesel gensets serve as the primary power source, enabling vital operations and supporting communities. Furthermore, emergency services like fire departments and disaster relief organizations rely on mobile diesel generators to provide power in crisis situations. The adaptability of diesel gensets to diverse power needs and environmental conditions underscores their importance in maintaining essential services and supporting economic activity worldwide. Have you ever considered just how many critical services rely on these often-unseen powerhouses?

Advantages of Choosing a Diesel Generator Set

Opting for a diesel generator set offers a multitude of advantages that make it a compelling choice for power generation needs. Foremost among these is reliability. Diesel engines are known for their robustness and longevity, capable of operating for extended periods under demanding conditions. Fuel efficiency is another significant benefit, particularly in applications requiring continuous or frequent operation. Diesel fuel, while subject to price fluctuations, generally offers a higher energy density compared to gasoline, translating to more kilowatt-hours per gallon. Durability and low maintenance are also key advantages; diesel engines are designed for heavy-duty use and require less frequent servicing compared to some other engine types. Furthermore, diesel generators are available in a wide range of power outputs, from small portable units to multi-megawatt industrial installations, providing scalability to match diverse power requirements. The combination of reliability, efficiency, durability, and scalability makes diesel gensets a highly practical and cost-effective power solution for a vast spectrum of applications.

Selecting the Right Diesel Generator Set: Key Considerations

Choosing the appropriate diesel generator set is a crucial decision that requires careful consideration of several factors to ensure optimal performance and meet specific power needs. The first and foremost consideration is power requirement. Accurately assessing the total power demand of the equipment and systems to be powered is essential to selecting a genset with sufficient capacity. It's generally recommended to factor in a safety margin to accommodate potential peak loads and future expansion. Next, consider the application: Is it for standby power, prime power, or continuous operation? This will influence the duty cycle and required features of the genset. Environmental factors, such as ambient temperature, altitude, and noise restrictions, also play a role in genset selection. Fuel availability and storage considerations are important, as is the level of automation and control required. Finally, budget constraints and long-term operating costs, including fuel, maintenance, and potential repairs, should be carefully evaluated. A thorough assessment of these factors will guide you towards selecting a diesel generator set that effectively and efficiently meets your power generation requirements. Thinking about these considerations upfront can save significant time and resources in the long run.

Maintenance and Longevity of Diesel Generator Sets

While diesel generator sets are renowned for their durability, regular maintenance is paramount to ensuring their continued reliability and extending their operational lifespan. A proactive maintenance schedule should include routine inspections, fluid checks (oil, coolant, fuel), filter replacements (air, oil, fuel), and battery maintenance. Engine tune-ups, alternator inspections, and control system checks should also be performed periodically, as recommended by the manufacturer's guidelines. Proper lubrication is critical to minimizing wear and tear on engine components. Fuel quality is another important factor; using clean, high-quality diesel fuel helps prevent fuel system issues and engine damage. Regular testing of the genset under load is essential to verify its performance and identify any potential problems before they escalate. By adhering to a comprehensive maintenance plan and addressing any issues promptly, owners can maximize the lifespan and ensure the dependable operation of their diesel generator set for years to come. Investing in regular maintenance is an investment in the long-term reliability of your power solution.

Future Trends and Innovations in Diesel Generator Technology

The field of diesel generator set technology is continuously evolving, driven by demands for greater efficiency, reduced emissions, and enhanced performance. Manufacturers are actively developing more fuel-efficient diesel engines, incorporating advanced combustion technologies and electronic controls to optimize fuel consumption and minimize operating costs. Emissions reduction is a major focus, with advancements in exhaust after-treatment systems, such as diesel particulate filters and selective catalytic reduction, significantly reducing harmful pollutants. Hybrid generator systems, combining diesel gensets with battery storage or renewable energy sources, are gaining traction, offering improved fuel efficiency and reduced environmental impact. Remote monitoring and control technologies are becoming increasingly sophisticated, enabling proactive maintenance and optimizing genset performance remotely. Furthermore, research into alternative fuels, such as biodiesel and synthetic diesel, is ongoing, with the potential to further enhance the sustainability of diesel generator technology. These innovations are ensuring that diesel gensets remain a relevant and evolving power solution for the future, adapting to changing environmental regulations and energy demands.

Conclusion: Diesel Generator Sets – A Reliable Power Solution for Today and Tomorrow

In conclusion, the diesel generator set stands as a testament to reliable and robust power generation. From its fundamental components to its diverse applications and ongoing technological advancements, the diesel genset continues to be a vital asset for ensuring power continuity across a multitude of sectors. Its inherent reliability, fuel efficiency, and adaptability make it a preferred choice for both standby and prime power needs. By understanding the key aspects of diesel generator technology, from selection and maintenance to future trends, users can make informed decisions to optimize their power solutions. As we move forward, the diesel generator set is poised to remain a cornerstone of power reliability, adapting and innovating to meet the evolving demands of a power-dependent world. For those seeking dependable power solutions, exploring the capabilities of diesel generator sets is a crucial step towards ensuring operational continuity and peace of mind. What are your primary power reliability concerns, and how might a diesel genset address them?

For more detailed information, please visit our official website: diesel generator set