In today's world, consistent and reliable power is the lifeblood of countless industries. From keeping data centers operational to ensuring hospitals can function during emergencies, the demand for uninterrupted electricity is paramount. When grid power falters, businesses and critical infrastructure turn to robust backup power solutions. Among these, the industrial diesel generator stands out as a workhorse, providing dependable and substantial power when it's needed most. These generators are not just about keeping the lights on; they are about maintaining productivity, ensuring safety, and safeguarding critical operations across a vast spectrum of sectors. Understanding their importance, functionality, and selection is crucial for any business or organization that relies on continuous power.

The Indispensable Role of Industrial Diesel Generators

The significance of an industrial diesel generator extends far beyond simple backup power. They serve as a primary power source in remote locations where grid access is limited or nonexistent, and they are crucial for peak shaving during periods of high energy demand, helping to reduce electricity costs. Consider the vast construction sites where heavy machinery and temporary facilities require substantial power, or the remote mining operations that are entirely reliant on on-site power generation. In these scenarios, diesel generators are not a contingency; they are the primary and often sole source of electrical energy. Moreover, in industries like telecommunications and manufacturing, even brief power outages can lead to significant financial losses and operational disruptions. Therefore, investing in a reliable industrial diesel generator is not just an operational expense, but a strategic investment in business continuity and resilience. Have you ever considered the potential impact of a power outage on your own operations? It’s a scenario that highlights the true value of having a dependable backup power system in place.

Understanding How Industrial Diesel Generators Work

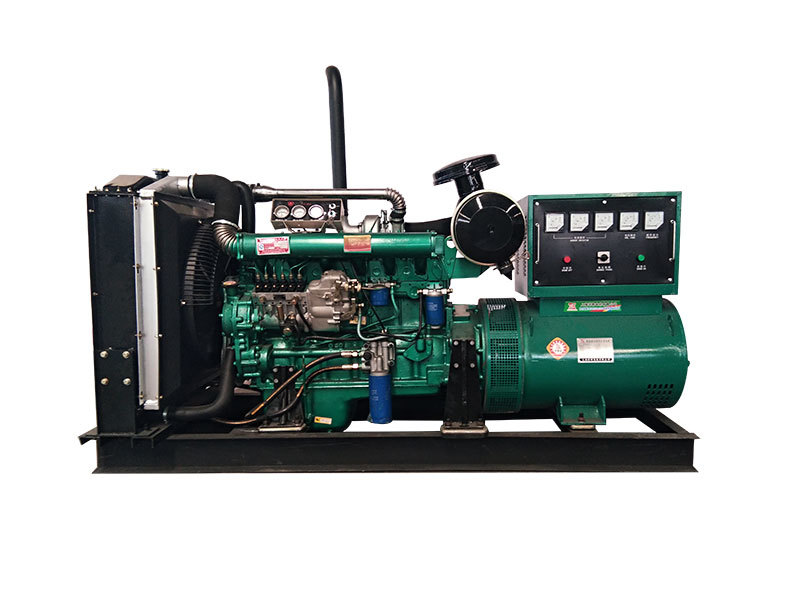

At their core, industrial diesel generators are relatively straightforward machines, but their engineering and construction are highly refined to ensure reliability and efficiency. The fundamental principle is the conversion of chemical energy in diesel fuel into mechanical energy, which is then converted into electrical energy. The process begins with a diesel engine, which combusts diesel fuel to drive a crankshaft. This crankshaft is mechanically coupled to an alternator, also known as a generator head. The alternator then utilizes electromagnetic induction to generate an electrical current. Modern industrial diesel generators are equipped with sophisticated control systems that monitor various parameters such as voltage, frequency, and load, ensuring stable and consistent power output. They also often incorporate features like automatic voltage regulation (AVR) and automatic transfer switches (ATS) to seamlessly switch between grid power and generator power during outages. Understanding these basic components and their interaction helps appreciate the robust nature of these power solutions.

Key Benefits of Choosing an Industrial Diesel Generator

There are compelling reasons why industrial diesel generators remain a preferred choice for backup and prime power applications. Firstly, their reliability is unmatched. Diesel engines are known for their durability and ability to operate under demanding conditions for extended periods. Secondly, they offer excellent fuel efficiency, especially at higher load factors, making them cost-effective for continuous or frequent use. Thirdly, diesel fuel is readily available and relatively inexpensive compared to other fuels in many regions. Furthermore, industrial diesel generators are available in a wide range of power outputs, from a few kilowatts to megawatts, making them scalable to suit diverse power requirements, from small businesses to large industrial complexes. Finally, advancements in technology have led to quieter and more environmentally friendly diesel generators, addressing some of the historical concerns related to noise and emissions. These advantages collectively make them a practical and dependable power solution for a multitude of applications.

Diverse Applications Across Industries

The versatility of the industrial diesel generator is evident in its widespread use across a multitude of sectors. In healthcare, hospitals rely on them to power life-support systems, operating rooms, and critical patient care areas during grid failures. Data centers, the backbone of the digital economy, depend on generators to maintain uninterrupted operation of servers and networking equipment, preventing data loss and service disruptions. Manufacturing plants utilize them to keep production lines running, minimizing downtime and ensuring consistent output. Construction sites benefit from their portability and ability to power heavy equipment and site facilities in areas without grid access. Even in the agricultural sector, large-scale farming operations use diesel generators for irrigation systems and powering processing facilities. From emergency services to critical infrastructure, the applications are vast and underscore their importance in keeping essential services functioning.

Selecting the Right Industrial Diesel Generator: Key Considerations

Choosing the appropriate industrial diesel generator is a crucial decision that requires careful evaluation of several factors. The first and foremost consideration is power requirement. Accurately assessing the total power demand of the equipment and systems to be supported is essential to select a generator with adequate capacity. It's always prudent to factor in future growth and potential increases in power needs. Secondly, consider the application type – is it for standby power, prime power, or continuous operation? This will influence the generator's duty cycle and required features. Fuel consumption, noise levels, and emission standards are also important considerations, especially in environmentally sensitive areas or densely populated urban environments. Finally, budget and maintenance requirements should be factored into the decision-making process. Investing in a higher quality, more efficient generator may have a higher upfront cost but can result in long-term savings through lower fuel consumption and reduced maintenance. Properly evaluating these factors will ensure that the selected generator meets your specific needs and provides reliable power for years to come.

Maintenance and Longevity of Your Industrial Diesel Generator

To ensure the continued reliability and longevity of an industrial diesel generator, regular and proactive maintenance is paramount. Like any complex machinery, diesel generators require routine servicing to operate optimally and prevent breakdowns. This includes regular inspections of fluid levels (oil, coolant, fuel), filter replacements (oil, air, fuel), battery checks, and testing of the generator's performance under load. Scheduled maintenance should follow the manufacturer's recommendations and be performed by qualified technicians. Proper maintenance not only extends the lifespan of the generator but also ensures its readiness when it's needed most during a power outage. Neglecting maintenance can lead to unexpected failures, reduced efficiency, and costly repairs. Investing in a comprehensive maintenance plan is a wise decision that safeguards your investment and ensures continuous power availability. What steps are you taking to ensure the upkeep of your backup power systems?

Environmental Considerations and Advancements in Diesel Technology

Historically, diesel engines have faced scrutiny regarding emissions. However, significant advancements in diesel technology have led to cleaner and more environmentally friendly industrial diesel generators. Modern generators are equipped with sophisticated emission control systems, such as diesel particulate filters (DPF) and selective catalytic reduction (SCR), which significantly reduce harmful pollutants like particulate matter, nitrogen oxides (NOx), and carbon monoxide (CO). Furthermore, manufacturers are increasingly focusing on fuel efficiency, which not only reduces operating costs but also lowers overall emissions. There's also growing interest in alternative fuels, such as biodiesel and renewable diesel, which can further minimize the environmental impact of diesel generators. While environmental concerns are valid, it's important to recognize the strides made in diesel technology and the availability of cleaner, more efficient generator models. Choosing a generator that meets current emission standards is a responsible and increasingly important consideration for businesses and organizations.

Future Trends in Industrial Diesel Generator Technology

The future of industrial diesel generators is likely to be shaped by several key trends. Hybrid power systems, combining diesel generators with renewable energy sources like solar or wind, are gaining traction. These hybrid systems offer a balance of reliability and sustainability, reducing reliance on fossil fuels while ensuring consistent power availability. Another trend is the integration of smart technologies and remote monitoring capabilities. Modern generators are increasingly equipped with sensors and communication systems that allow for remote performance monitoring, predictive maintenance, and automated diagnostics. This enhances operational efficiency and reduces downtime. Furthermore, research and development efforts are focused on improving engine efficiency, reducing emissions further, and exploring alternative fuels that can be used in diesel generators. These advancements suggest that diesel generators will continue to play a vital role in the power generation landscape, evolving to meet the changing demands of industries and environmental considerations.

In conclusion, industrial diesel generators remain a cornerstone of reliable power solutions for a wide range of industries. Their dependability, versatility, and continuous technological advancements ensure they will continue to be a critical asset for businesses and organizations requiring backup or prime power. From hospitals and data centers to construction sites and remote operations, their ability to provide consistent power is indispensable. Our company offers a comprehensive range of industrial diesel generators designed to meet diverse power needs and ensure business continuity. We are committed to providing high-quality, reliable, and efficient power solutions to support your critical operations. Choosing the right generator and implementing a robust maintenance plan are key to maximizing its benefits and ensuring years of dependable service. If you are looking for a reliable power solution, consider the proven performance and enduring value of an industrial diesel generator.

For more detailed information, please visit our official website: industrial diesel generator