The reliable operation of a 500kVA generator set is paramount for numerous applications, from industrial facilities and data centers to remote construction sites and critical infrastructure. However, when these powerful machines are deployed in hot climates, the challenge of maintaining optimal operating temperatures becomes significantly more complex. Effective cooling system design is not merely an accessory; it is the very backbone of ensuring consistent performance, preventing costly downtime, and extending the lifespan of the generator set. In environments where ambient temperatures frequently soar, a standard cooling approach simply won't suffice. We must delve into the intricacies of thermal management, exploring advanced strategies and technologies tailored to withstand the rigors of heat and humidity. This article will explore the critical considerations and design principles behind robust cooling systems for 500kVA generator sets operating in demanding hot climate conditions.

Understanding the Thermal Challenge in Hot Climates

Operating a 500kVA generator set in a hot climate presents a unique set of thermal management challenges. It’s not just the ambient temperature that's the issue; it’s the cumulative effect of high ambient heat, direct sunlight, and the generator's own heat generation during operation. Internal combustion engines, especially those powering generators of this size, produce a substantial amount of heat as a byproduct of energy conversion. This heat must be efficiently dissipated to prevent overheating, which can lead to a cascade of problems. Reduced power output, decreased fuel efficiency, accelerated wear and tear on engine components, and in severe cases, catastrophic engine failure are all potential consequences of inadequate cooling. In hot climates, the already challenging task of heat dissipation is exacerbated by the reduced temperature differential between the generator set and the surrounding environment. This reduced differential makes it harder for traditional cooling methods to effectively transfer heat away from the engine and alternator, demanding more sophisticated and robust cooling solutions.

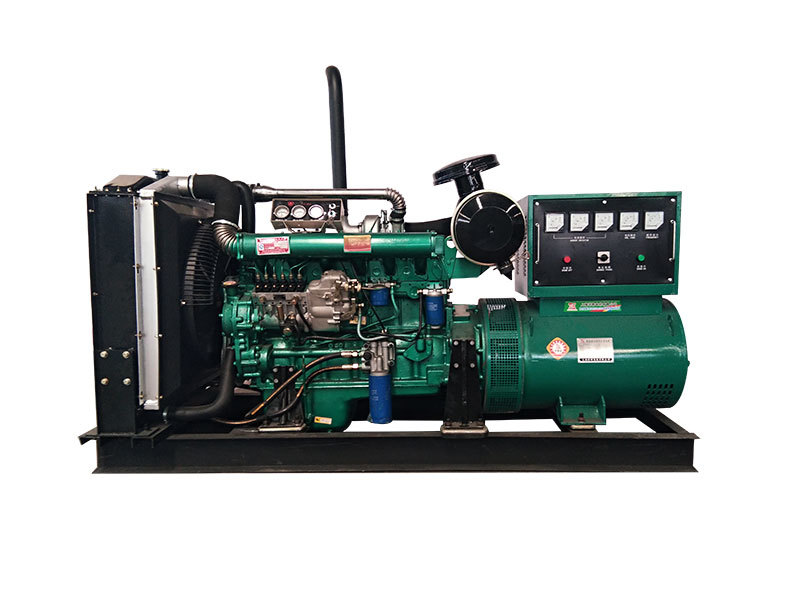

Key Components of a 500kVA Generator Cooling System

A comprehensive cooling system for a 500kVA generator set is more than just a radiator and a fan. It’s an integrated system comprising several key components working in concert to manage heat effectively. The core components include the radiator, responsible for dissipating heat from the engine coolant; the cooling fan, which forces air across the radiator to enhance heat transfer; the coolant pump, circulating coolant throughout the engine and radiator; and the thermostat, regulating coolant temperature to maintain optimal engine operating conditions. In hot climates, these components often need to be uprated or supplemented with additional features. For instance, larger radiators with increased surface area, high-efficiency cooling fans with greater airflow capacity, and robust coolant pumps capable of handling higher temperatures are often necessary. Furthermore, the selection of coolant itself is crucial. Coolants designed for high-temperature environments, offering superior heat transfer properties and corrosion protection, are essential for maintaining cooling system efficiency and longevity under extreme thermal stress. Understanding each component’s role and ensuring their suitability for hot climate operation is paramount for effective cooling system design.

Air-Cooled vs. Liquid-Cooled Systems: Considerations for Hot Climates

Generator sets typically employ either air-cooled or liquid-cooled systems. For 500kVA generators operating in hot climates, liquid-cooled systems are almost invariably the preferred choice due to their superior heat management capabilities, especially at higher power outputs. Air-cooled systems, while simpler in design and maintenance, rely solely on air circulation to dissipate heat. In hot climates, the already warm ambient air has limited capacity to effectively cool a large 500kVA generator engine, potentially leading to overheating issues. Liquid-cooled systems, on the other hand, utilize a coolant fluid to absorb heat from the engine and then transfer it to a radiator where it is dissipated to the air. This two-stage process is significantly more efficient at removing heat, particularly in high ambient temperature conditions. Liquid cooling offers better temperature control, reduces engine noise, and generally provides more reliable performance for larger generators operating under heavy loads and in hot environments. While air-cooled options might exist for smaller generators, for the 500kVA class in hot climates, liquid cooling is the standard for ensuring operational reliability and longevity.

Enhancing Radiator Performance in High Ambient Temperatures

The radiator is the primary heat exchanger in a liquid-cooled generator set, and its performance is critical in hot climates. To maximize radiator efficiency in high ambient temperatures, several design and operational considerations come into play. Firstly, radiator size and surface area are paramount. Larger radiators with increased fin surface area provide greater heat dissipation capacity. Selecting radiators constructed from materials with high thermal conductivity, such as copper or aluminum alloys, also enhances heat transfer. Secondly, airflow across the radiator is crucial. High-efficiency cooling fans, often with variable speed drives, can optimize airflow based on engine temperature and load. Fan shrouds are also important to ensure that airflow is directed effectively through the radiator core, preventing air recirculation and maximizing cooling efficiency. Regular radiator maintenance, including cleaning to remove debris and ensuring proper coolant levels and condition, is also essential for sustained performance. In extremely hot climates, supplementary cooling methods like radiator misters or evaporative coolers, which pre-cool the air entering the radiator, can further enhance cooling capacity, although these introduce additional complexity and maintenance requirements.

Optimizing Coolant and Coolant Circulation

The coolant itself plays a vital role in the overall cooling system effectiveness, particularly in hot climates. Selecting the right type of coolant is not just about preventing freezing; it’s primarily about maximizing heat transfer and protecting engine components from corrosion and cavitation at high temperatures. High-quality coolants designed for heavy-duty engines and high-temperature operation often incorporate advanced additives that enhance heat transfer, raise boiling points, and prevent scale buildup. The coolant circulation system, driven by the coolant pump, must also be robust enough to maintain adequate flow rates even under high thermal loads. In hot climates, it's worth considering coolant pumps with increased capacity or even auxiliary coolant pumps to ensure sufficient coolant flow, particularly during peak load conditions or extended operation. Regular coolant checks and replacements, following manufacturer recommendations, are crucial for maintaining coolant effectiveness and preventing cooling system degradation. Have you ever considered the long-term impact of using substandard coolant in a hot climate? It’s a seemingly small detail that can have significant consequences for generator reliability and lifespan.

Enclosure Design and Ventilation for Hot Climate Generator Sets

The generator set enclosure plays a significant role in overall cooling system performance, especially in hot climates. A poorly designed enclosure can trap heat, hindering airflow and reducing the effectiveness of the cooling system. Enclosure design must prioritize ventilation to facilitate heat dissipation. This includes incorporating appropriately sized air intake and exhaust vents strategically positioned to promote cross-ventilation and prevent hot air recirculation within the enclosure. Louvered vents, which allow airflow while providing some protection from the elements, are commonly used. Furthermore, the enclosure material itself can impact heat absorption. Light-colored enclosures reflect more solar radiation, reducing heat buildup compared to dark-colored enclosures. In particularly demanding hot climates, forced ventilation systems, using auxiliary fans to actively draw cool air into the enclosure and expel hot air, may be necessary. The placement of the generator set is also a factor. Positioning the generator in a shaded area or orienting it to minimize direct sunlight exposure can reduce the thermal load on the cooling system. Effective enclosure design and ventilation are crucial for creating a more favorable operating environment for the generator set in hot climates.

Advanced Cooling Technologies for Extreme Heat

For extremely hot climates or applications demanding peak performance under severe thermal stress, advanced cooling technologies can offer significant advantages. These technologies go beyond conventional radiator and fan systems to provide enhanced cooling capacity. One such technology is evaporative cooling, which utilizes the principle of evaporative cooling to pre-cool intake air for the radiator, significantly increasing cooling efficiency. Another approach is the use of two-stage cooling systems, where a secondary cooling loop and heat exchanger are added to further reduce coolant temperature before it enters the engine. For critical applications, redundant cooling systems, incorporating backup radiators, fans, and coolant pumps, can provide an extra layer of security against cooling system failures. Thermoelectric cooling, while less common for large generator sets due to efficiency limitations, can be used for targeted cooling of specific components. These advanced technologies often involve higher upfront costs and increased complexity but can be justified in situations where operational reliability and performance in extreme heat are paramount. It’s worth noting that the selection of advanced cooling technologies should be based on a thorough assessment of the specific operating environment and performance requirements.

Maintenance and Best Practices for Hot Climate Cooling Systems

Even the most sophisticated cooling system requires diligent maintenance to ensure continued performance, especially in the harsh conditions of hot climates. Regular maintenance is not an option; it’s a necessity for preventing breakdowns and maximizing the lifespan of the generator set. Key maintenance tasks include regular inspection of coolant levels and condition, checking for leaks, and replacing coolant at recommended intervals. Radiator fins should be cleaned regularly to remove dust, debris, and insects that can impede airflow and reduce heat transfer efficiency. Cooling fan blades should be inspected for damage and proper operation, and fan belts (if applicable) should be checked for tension and wear. The thermostat should be tested periodically to ensure it is functioning correctly and regulating coolant temperature within the specified range. In dusty environments, air filters for the engine and enclosure ventilation system need more frequent replacement to maintain airflow and prevent overheating. Implementing a proactive maintenance schedule, tailored to the specific operating environment and generator set model, is crucial for ensuring the long-term reliability of the cooling system and the generator set as a whole. Ignoring these seemingly routine checks can lead to significant problems down the line, especially in demanding hot climates.

Our Solutions for Generator Cooling in Hot Climates

At our company, we understand the critical importance of robust cooling systems for generator sets operating in hot climates. We offer a range of generator sets, including 500kVA models, specifically designed and engineered to excel in demanding thermal environments. Our generator sets incorporate advanced cooling system designs, including oversized radiators, high-efficiency cooling fans, and optimized coolant circulation systems. We utilize high-quality coolants formulated for high-temperature operation and offer options for enhanced enclosure ventilation and advanced cooling technologies for extreme heat applications. Furthermore, we provide comprehensive maintenance and support services to ensure the continued reliability of your generator sets in hot climates. Our expert team can assist you in selecting the right generator set and cooling system configuration for your specific needs and operating conditions. We are committed to providing solutions that deliver dependable power, even in the most challenging environments, ensuring your operations remain uninterrupted and efficient. Choosing the right cooling system is an investment in the long-term performance and reliability of your 500kVA generator set, and we are here to partner with you in making that critical decision.

For more detailed information, please visit our official website: Cooling system design